Method for self-heating pyrolysis gasification of biomass by gas backflow combustion

A technology of pyrolysis gasification and biomass, which is applied in the manufacture of combustible gas, petroleum industry, energy input, etc. It can solve the problems of difficulty in establishing an oxidation and reduction reaction balance mechanism, low gas transmission efficiency, and high nitrogen content, and achieve low content , rapid response and high gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

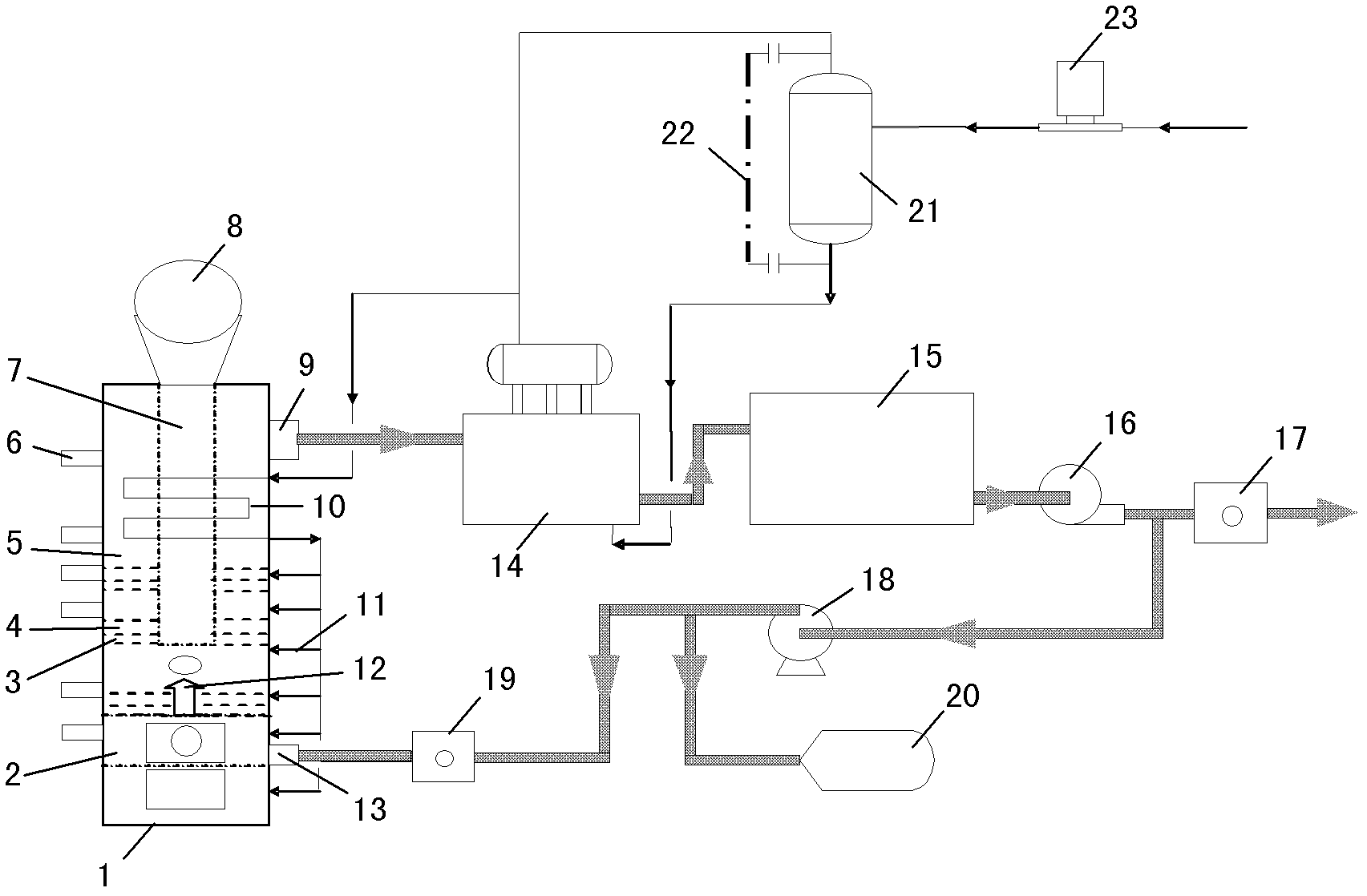

Method used

Image

Examples

Embodiment 1

[0024] Use fast-growing eucalyptus as raw material to produce combustible gas.

[0025] 1. Crush the fast-growing eucalyptus branches with a crusher and sort them to obtain materials with a size of 2-5mm.

[0026] 2. Before the formal start of the experiment, the gasifier first goes through the start-up phase, and charcoal and coke are used as starting materials in the start-up phase. Two tasks need to be completed in the start-up phase: first, to raise the temperature of the temperature measuring point of the gasifier to: the temperature of the first temperature measuring point at the bottom of the gasifier is > 1100°C, and the third from the top of the gasifier The temperature at the temperature measuring point is >650°C; secondly, the preparation of water vapor required by the gasification furnace is completed.

[0027] 3. Pour 162 kg of crushed and screened fast-growing eucalyptus into the hopper 8 one after another, and use a frequency converter to adjust the frequency o...

Embodiment 2

[0037] 1. Crush cassava stalks with a crusher and sort them to obtain 162kg of 1-3mm materials.

[0038] 2. The start-up and gas production stages of the gasifier are the same as in Example 1.

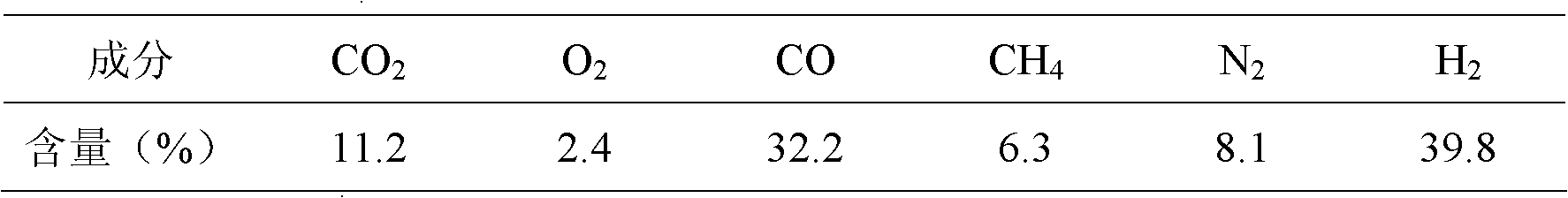

[0039] 3. Experimental results

[0040] Gas production is 252.7m 3 , the obtained combustible gas component content is shown in Table 3.

[0041] Table 3 Contents of combustible gas components

[0042]

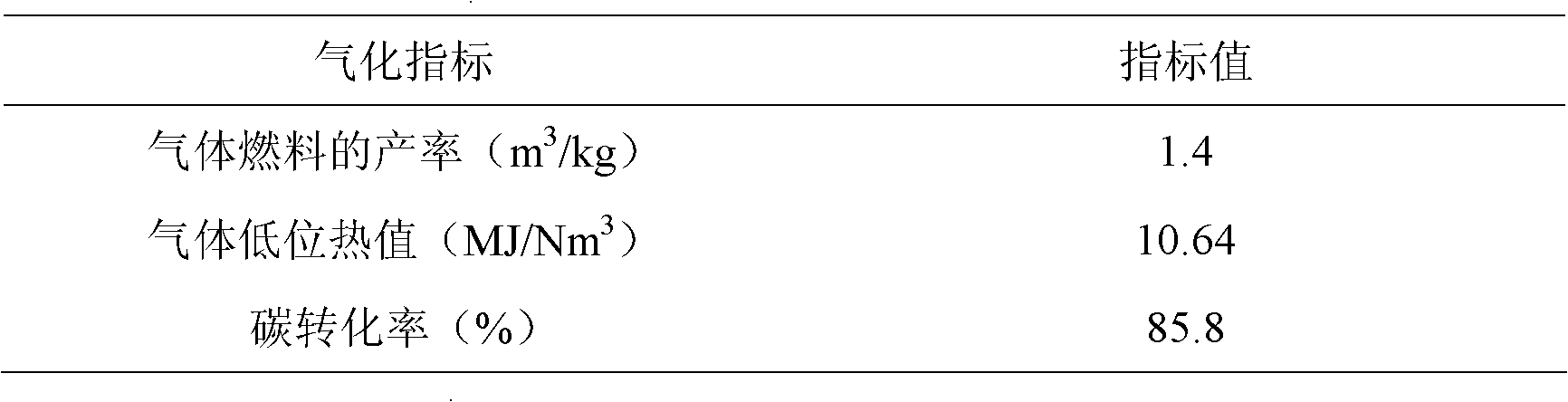

[0043] 4. Gasification index

[0044] The gasification index of the experiment is shown in Table 4

[0045] Table 4 Gasification indicators

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com