Boriding method of wear-resisting composite member

An assembly and boronizing technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems affecting the connection strength of the assembly, affecting the boronizing effect, and welding and falling off in the welding area of the assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

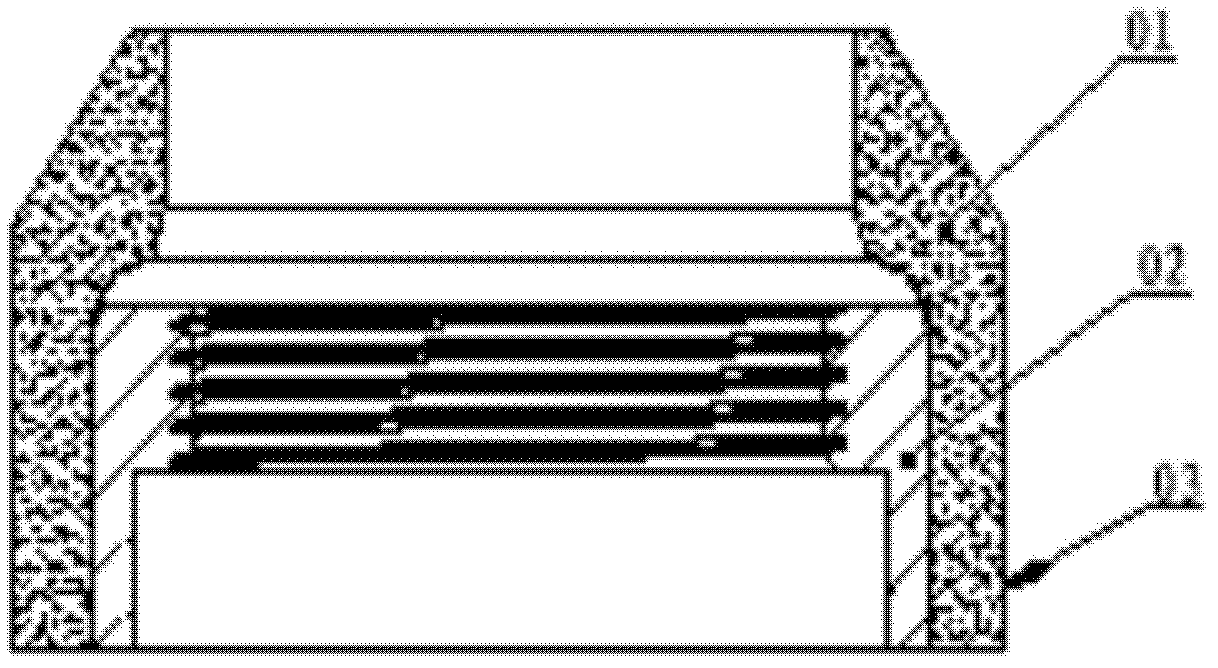

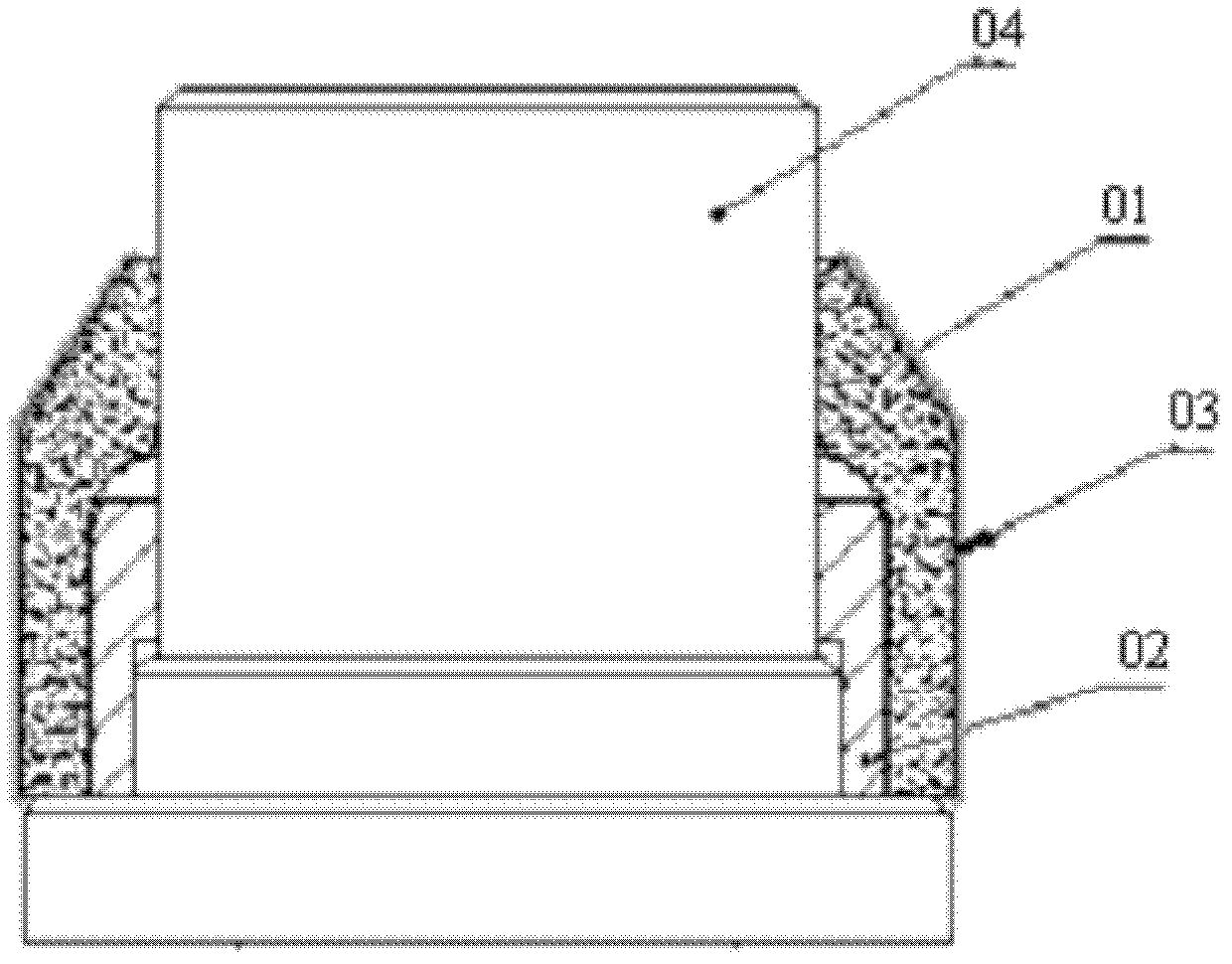

[0032] a) Match the wear-resistant assembly with a stepped mandrel and clamp it on the rotary table, such as figure 1 with figure 2 as shown, figure 1 Schematic diagram of the structure of the wear-resistant assembly, figure 2 It is a schematic diagram of the wear-resistant assembly installed on the workbench. In the figure, 01 is the tungsten-cobalt alloy part, 02 is the stainless steel part, 03 is the working surface of the wear-resistant assembly, and 05 is the workpiece through the mandrel.

[0033] b) placing the prepared anhydrous borax, sodium carbonate and rare earth in the charging cylinder of the thermal spray gun;

[0034] c) Start the rotary table and ignite the spray gun to uniformly heat the outer surface of the workpiece, and use a digital display induction thermometer to detect the surface temperature. When the temperature reaches 850°C, start spraying boronizing agent evenly on the circumference of the workpiece to form a boronizing layer. Wear-resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com