Prepolymer, oriented film, preparation method for oriented film, and liquid crystal display device

A technology of liquid crystal display devices and prepolymers, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of loss of orientation performance, intolerance to solvents, large pretilt angle, etc., to improve alignment performance and enhance chemical stability , Reduce the effect of repulsive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In addition, the present invention also provides the preparation method of above-mentioned alignment film, and this method comprises the following steps:

[0052] 1) dissolving the above-mentioned polyimide prepolymer in an organic solvent, stirring evenly, coating it on a glass substrate, drying to remove the solvent and forming a film;

[0053] 2) Raise the temperature to 350-400°C to cross-link the phenylacetylene groups.

[0054] The above-mentioned organic solvent is not particularly limited as long as it is a high-boiling-point aprotic solvent, for example, N-methylpyrrolidone, DMAc (N, N-dimethylacetamide), DMF (N, N-dimethylformamide) can be used. )Wait. The above-mentioned coating method is not particularly limited, for example, spin coating, roll coating, brush coating, knife coating, dip coating, curtain coating, spray coating, gravure coating, etc. can be used, and spin coating is preferred. The drying can be carried out in a vacuum oven by increasing the ...

preparation example 1

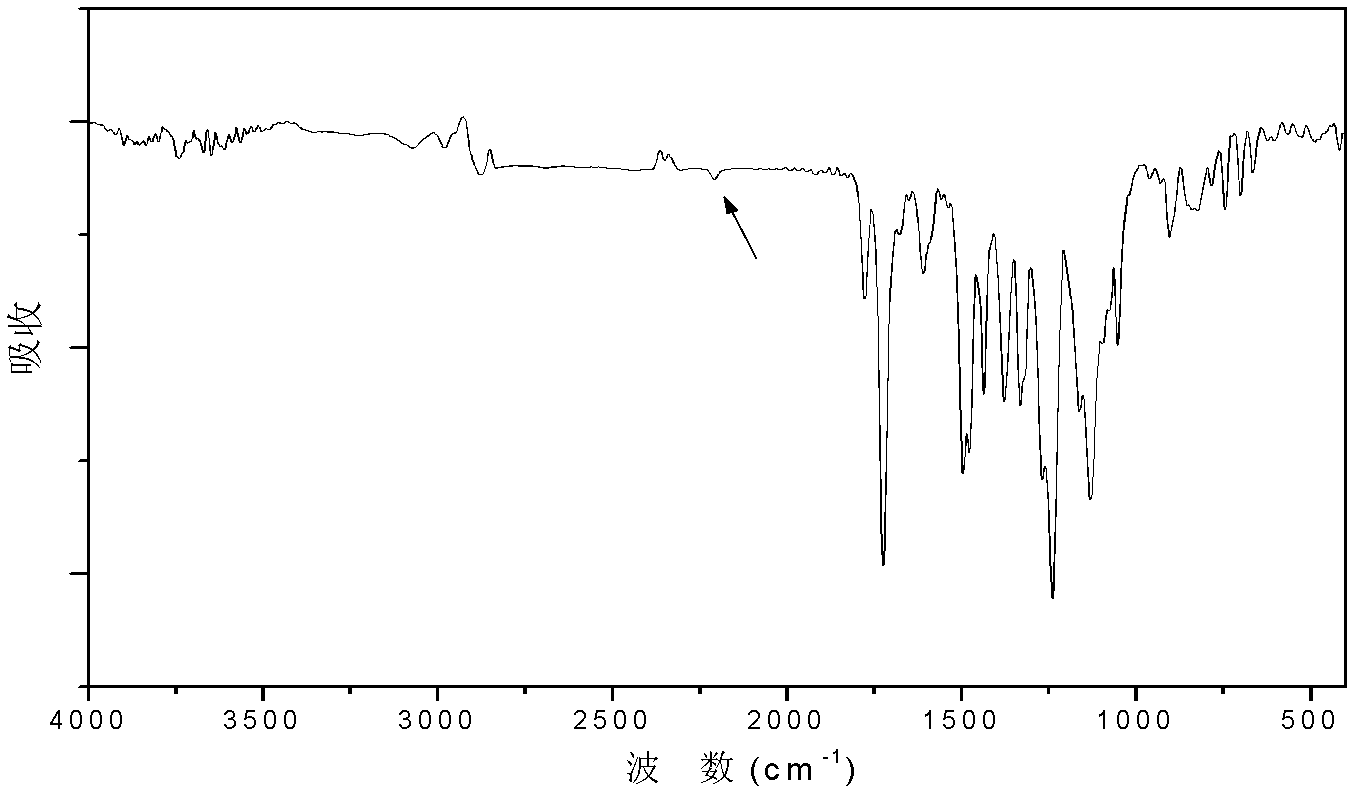

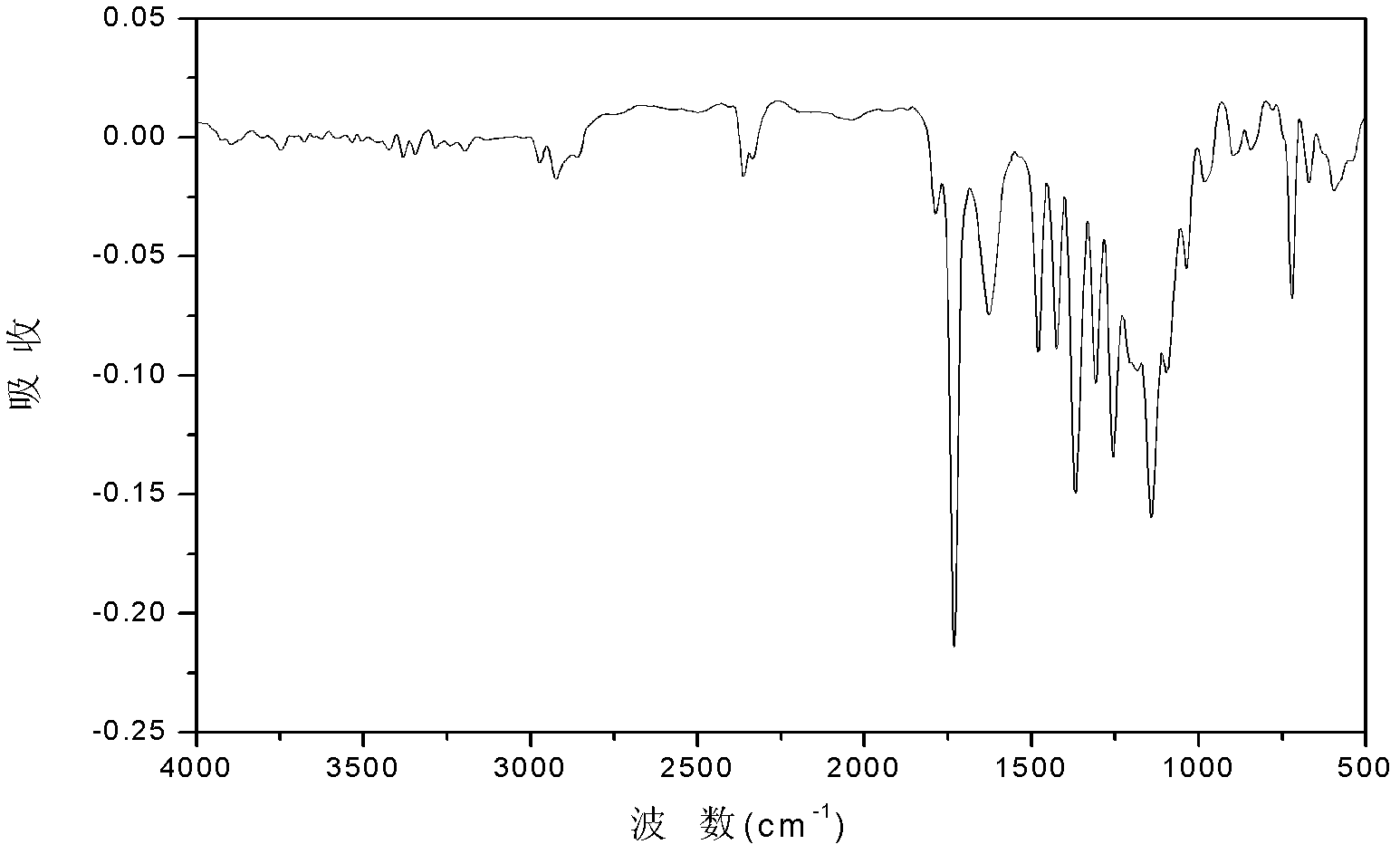

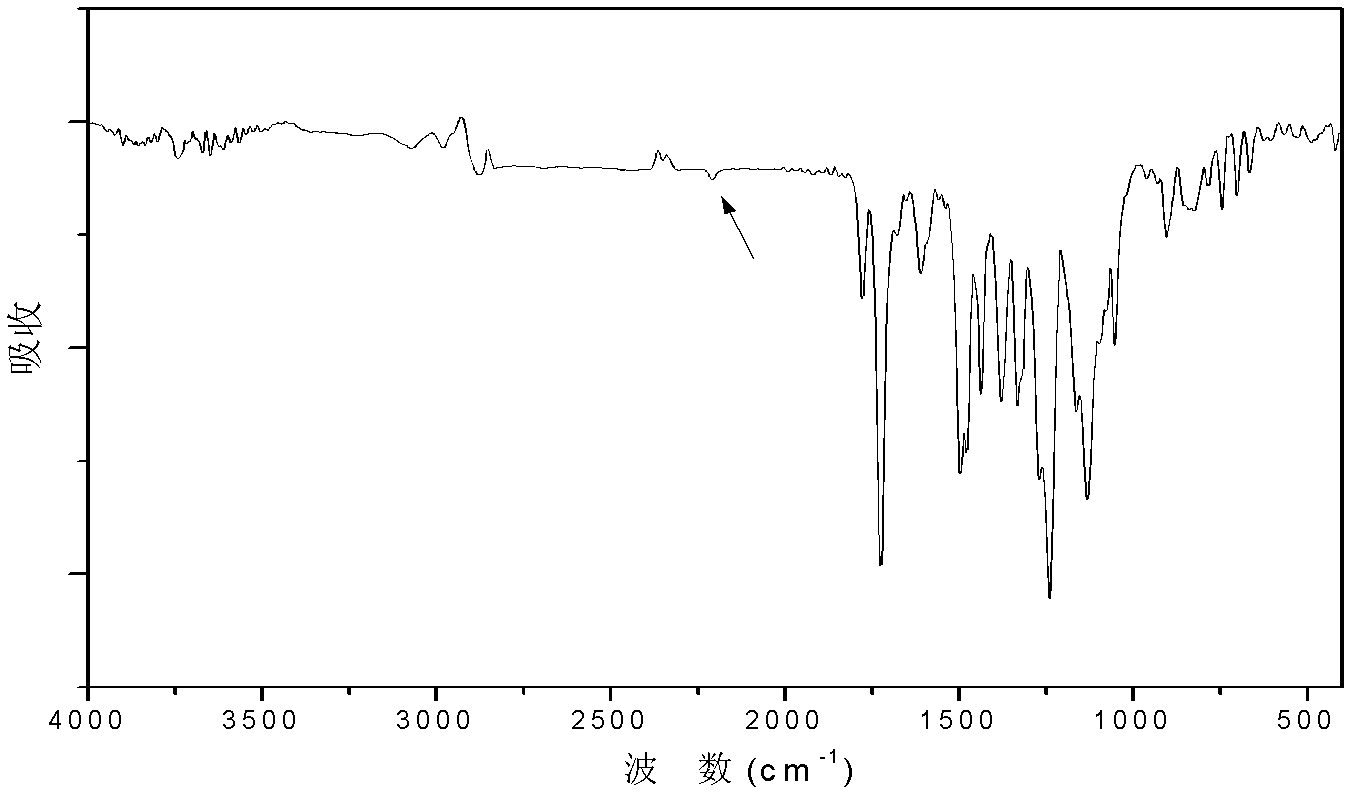

[0058] Preparation Example 1: Preparation of PENA

[0059] Add 4-bromo-1,8-naphthalene anhydride ( AR, Anshan Huifeng Chemical Co., Ltd.) 10g, phenylacetylene 5.5g (6ml) (AR, Sigma-Aldrich Company), triphenylphosphine 0.1956g (CP, Shanghai Reagent No. 1 Factory), cuprous iodide 0.0657 g (AR, Sigma-Aldrich Company), triphenylphosphine palladium dichloride 0.0322g (AR, Sigma-Aldrich Company), 50ml distilled triethylamine (AR, Tianjin Chemical Reagent No. 2 Factory), 100ml toluene (AR, Beijing Chemical Reagent No. 1 Factory), the reaction mixture was slowly heated to reflux with an oil bath for 6.5 hours under the condition of feeding nitrogen, while keeping the nitrogen unobstructed. It can be observed that a yellow-white solid precipitates on the wall of the reaction bottle, and it is cooled and filtered to obtain a yellow solid. Afterwards, the catalyst and the inorganic salt produced by the reaction were washed away with distilled water, dried at 120°C for 2 hours, and recr...

preparation example 2

[0060] Preparation Example 2: Preparation of diamine monomer 1,4-bis(4-amino-2-trifluoromethylphenoxy)-2-(3'-trifluoromethylphenyl)benzene

[0061] The 1,4-bis(4-amino-2-trifluoromethylphenoxy)-2-(3'-trifluoromethylphenyl)benzene used in the examples is prepared according to the following chemical formula, and the specific steps are as follows stated.

[0062] Preparation of dinitromonomer: Add 0.2mol (50.84g) of trifluoromethylbisphenol to a 1000ml three-necked flask equipped with mechanical stirring, nitrogen vent, water device (Dean-Stark trap), and reflux condenser (According to the literature: Liu BJ, Wang GB, Hu W, Jin YH, Chen CH, Jiang ZH, et al.J Polym Sci Part A Polym Chem 2002; 40:3392 The method described in preparation), 2-chloro-5- Nitro-3-trifluorotoluene 0.4mol (90.22g) (AR, Shanghai Shandao Chemical Co., Ltd.), anhydrous potassium carbonate 0.24mol (33.12g) (AR, Tianjin Chemical Reagent Factory), DMF 500ml (AR, Tianjin Tiantai Fine Chemicals Co., Ltd.) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com