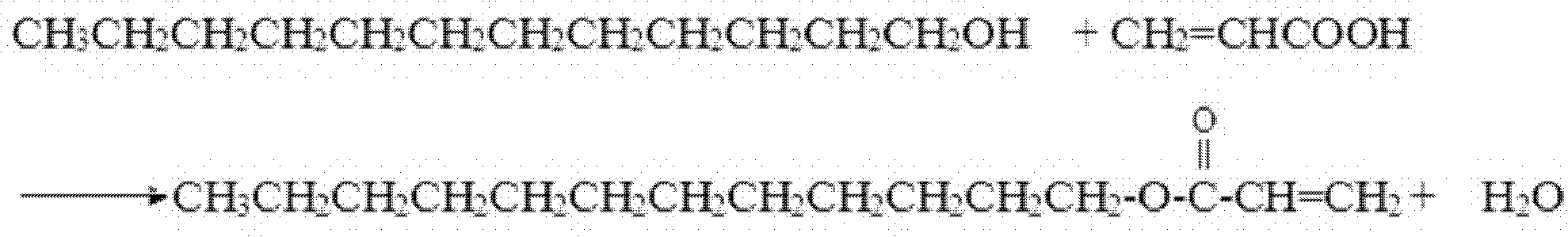

Pollution-free production method of lauryl alcohol acrylate, hexadecanol acrylate or stearyl alcohol acrylate

A technology of palm alcohol acrylate and lauryl acrylate, applied in the field of photocurable materials, can solve the problems of water environment pollution, high treatment cost and high manufacturing cost, achieve high yield, ensure yield and quality, and have excellent environmental benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]In the 3000L reactor, drop into 500 kilograms of toluene, 290 kilograms of cyclohexane, 711 kilograms of lauryl alcohol (molecular weight 186), 289 kilograms of acrylic acid, 8 kilograms of p-hydroxyanisole, 4 kilograms of hypophosphorous acid, 55 kilograms of p-toluenesulfonic acid; Stir, continuously feed compressed air into the kettle through the distributor at the bottom of the kettle, heat up to 85-95°C and start reflux dehydration, esterification reaction for 9-10 hours, kettle temperature 95-105°C, when reflux dehydration until no water comes out, Detect the acid value of 10-25mgKOH / g, after the reaction is over, cool to 40°C; add 25 kg of caustic soda and 60 kg of water, and stir for 30 minutes; add 6 kg of magnesium polysilicate, stir and absorb for 30 minutes; Above MPa, water and solvent are distilled under reduced pressure at 50-95°C. After the recovered water and solvent are separated, the water can be used directly in the next neutralization without any trea...

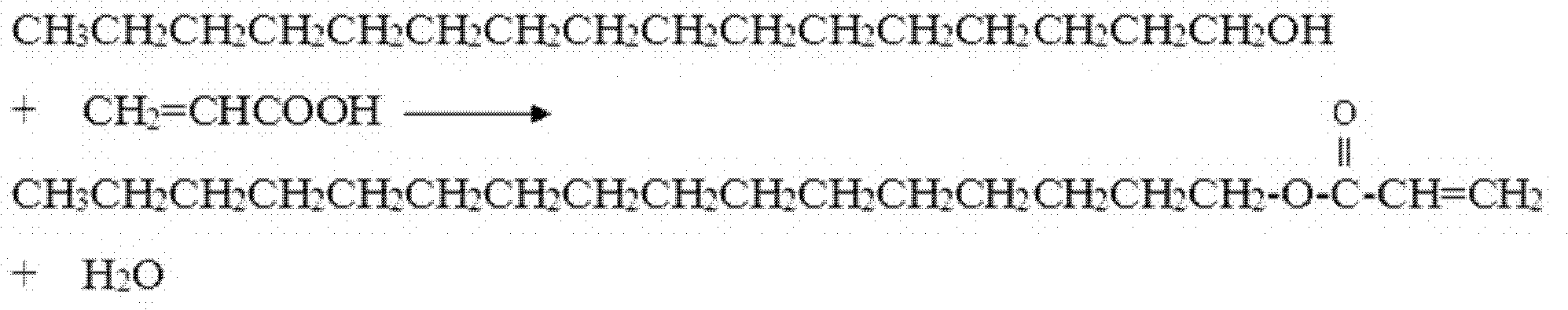

Embodiment 2

[0043] In the 3000L reactor, drop 585 kilograms of cyclohexane, 1108 kilograms of palmitic alcohol (molecular weight 242.5), 362 kilograms of acrylic acid, 6 kilograms of p-hydroxyanisole, 3 kilograms of sodium hypophosphite, 30 kilograms of methanesulfonic acid; The bottom distributor continuously feeds compressed air into the kettle, raises the temperature to 80-85°C and starts reflux dehydration, the esterification reaction lasts for 10-12 hours, the kettle temperature is 85-92°C, when the reflux dehydration reaches anhydrous, the acid value is detected to be 10 ~25mgKOH / g, after the reaction is over, cool to 40°C; add 32 kg of caustic soda and 75 kg of water, and stir for 30 minutes; add 6.5 kg of magnesium polysilicate, stir and absorb for 30 minutes; Distill water and solvent under reduced pressure at -95°C; after the recovered water and solvent are separated, the water can be used directly in the next neutralization without any treatment, and the solvent can be used dire...

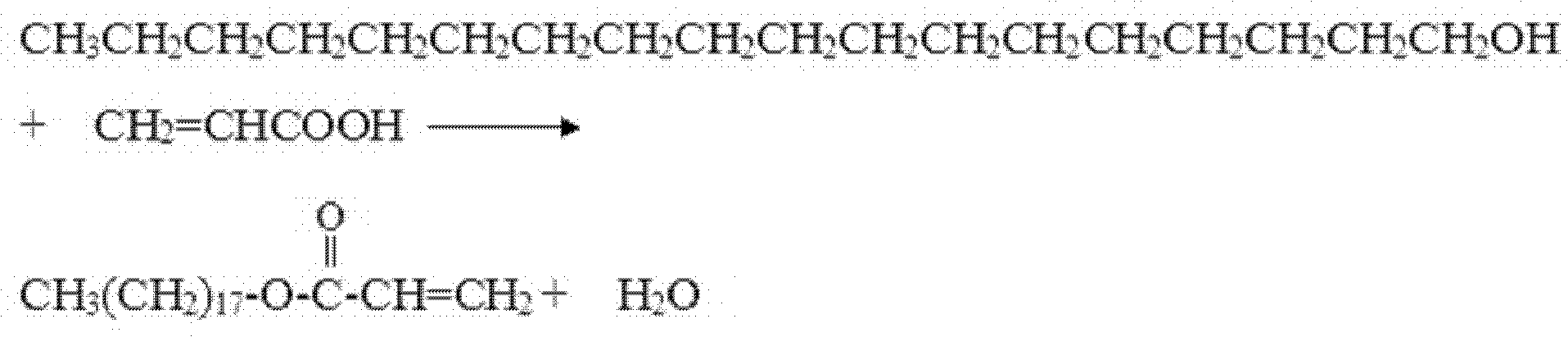

Embodiment 3

[0045] 162 kg of methylcyclopentane, 198 kg of toluene, 1345 kg of stearyl alcohol (molecular weight 270.5), 390 kg of acrylic acid, 7.2 kg of p-hydroxyanisole, 1.8 kg of hypophosphorous acid, and 25.6 kg of methanesulfonic acid were put into the 3000L reactor ; Turn on stirring, continuously feed compressed air into the kettle through the distributor at the bottom of the kettle, raise the temperature to 85-95°C and start reflux dehydration, the esterification reaction is 9-10 hours, the kettle temperature is 95-105°C, when the reflux dehydration reaches anhydrous When the acid value is 10-25mgKOH / g, after the reaction is over, cool to 40°C; add 43 kg of caustic soda and 108 kg of water, and stir for 30 minutes; add 17.3 kg of magnesium polysilicate, stir and absorb for 30 minutes; Above -0.098MPa, water and solvent are distilled under reduced pressure at 50-95°C. After the recovered water and solvent are separated, the water can be used directly in the next neutralization with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com