Method for preparing Tb-doped BiFeO3 ferroelectric film on surface of conductive glass substrate

A technology for conducting glass and substrate surface, applied in the field of functional materials, can solve the problems of low dielectric constant of bismuth ferrite material, large leakage conductance of bismuth ferrite material, difficult to observe large remanent polarization value, etc., so as to improve the residual polarization value. Polarization value, the effect of suppressing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Select the FTO conductive glass substrate as the substrate, place the cut FTO conductive glass substrate in detergent, acetone, and ethanol for ultrasonic cleaning for 10 minutes to remove impurities such as grease on the surface of the FTO conductive glass substrate; After cleaning, rinse the substrate with a large amount of distilled water, and finally dry it with nitrogen;

[0027] Step 2: Place the clean FTO conductive glass substrate in a UV irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanliness", form hydroxyl groups with better hydrophilicity, and improve the hydrophilicity of the substrate;

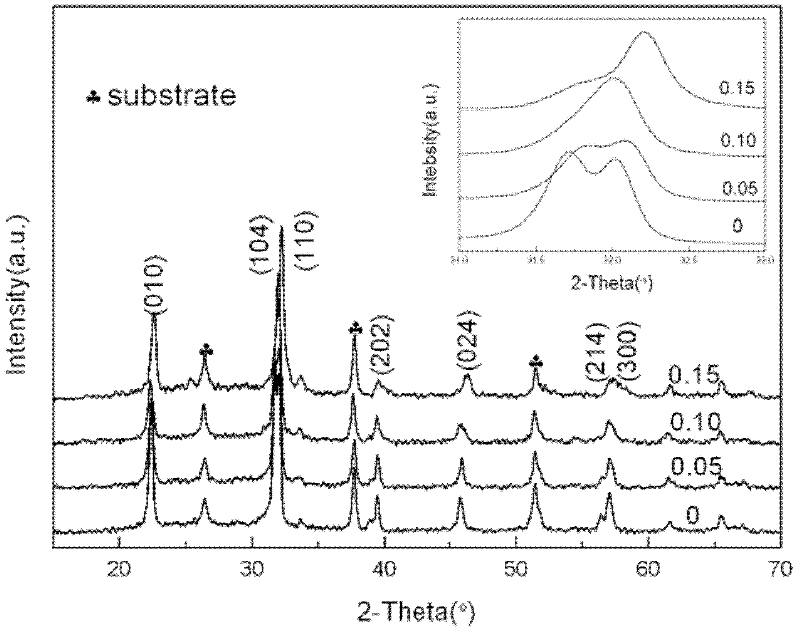

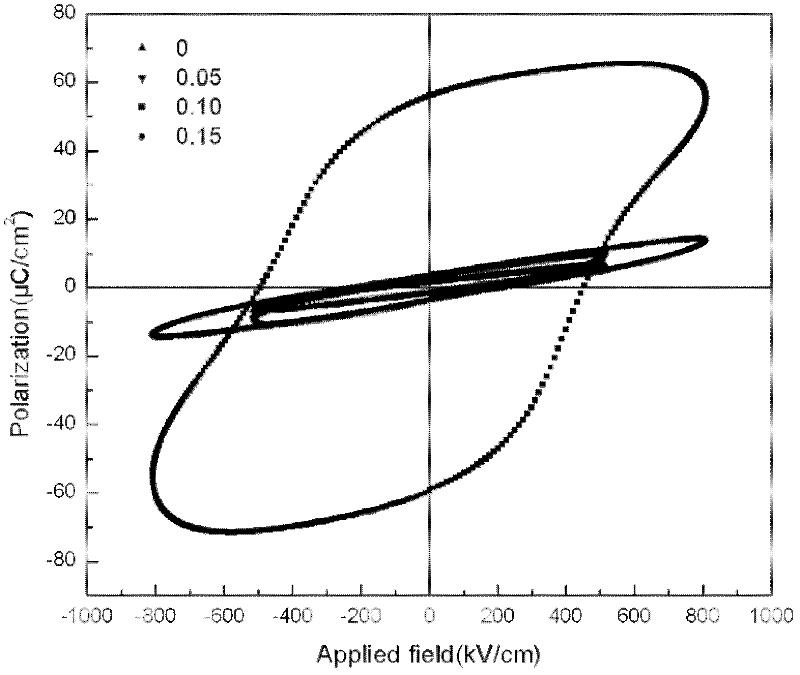

[0028] Step 3: Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O and Tb(NO 3 ) 3 ·5H 2 O was dissolved in a mixture of ethylene glycol methyl ether and glacial acetic acid at a molar ratio of 1:0.95:0.05 to obtain a precursor solution with a metal ion concentration of 0.3-0.9 mol / L, and magnetically stirred for 0.5 h to obtain stable ...

Embodiment 2

[0032] Step 1: Select the FTO conductive glass substrate as the substrate, place the cut FTO conductive glass substrate in detergent, acetone, and ethanol for ultrasonic cleaning for 10 minutes to remove impurities such as grease on the surface of the FTO conductive glass substrate; After cleaning, rinse the substrate with a large amount of distilled water, and finally dry it with nitrogen;

[0033] Step 2: Place the clean FTO conductive glass substrate in a UV irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanliness", form hydroxyl groups with better hydrophilicity, and improve the hydrophilicity of the substrate;

[0034] Step 3: Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O and Tb(NO 3 ) 3 ·5H 2 O was dissolved in a mixture of ethylene glycol methyl ether and glacial acetic acid at a molar ratio of 1:0.90:0.10 to obtain a precursor solution with a metal ion concentration of 0.3-0.9 mol / L, and magnetically stirred for 0.5 h to obtain stable ...

Embodiment 3

[0038] Step 1: Select the FTO conductive glass substrate as the substrate, and place the cut FTO conductive glass substrate in detergent, acetone, and ethanol for ultrasonic cleaning for 10 minutes to remove grease and other impurities on the surface of the FTO conductive glass substrate. Rinse the substrate with a large amount of distilled water after each ultrasonic cleaning, and finally dry it with nitrogen;

[0039] Step 2: Place the clean FTO conductive glass substrate in a UV irradiator for 40 minutes to make the surface of the substrate reach "atomic cleanliness", form hydroxyl groups with better hydrophilicity, and improve the hydrophilicity of the substrate;

[0040] Step 3: Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O and Tb(NO 3 ) 3 ·5H 2 O was dissolved in a mixture of ethylene glycol methyl ether and glacial acetic acid at a molar ratio of 1:0.85:0.15 to obtain a precursor solution with a metal ion concentration of 0.3-0.9 mol / L, and magnetically stirred for 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com