Method for preparing large-size lanthanum gallium silicate crystals in batches

A technology of lanthanum silicate and large size is applied in the field of batch preparation of large size lanthanum silicate crystals to achieve the effects of reducing processing loss and man-hours, low equipment cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

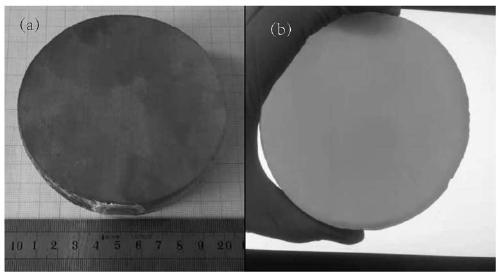

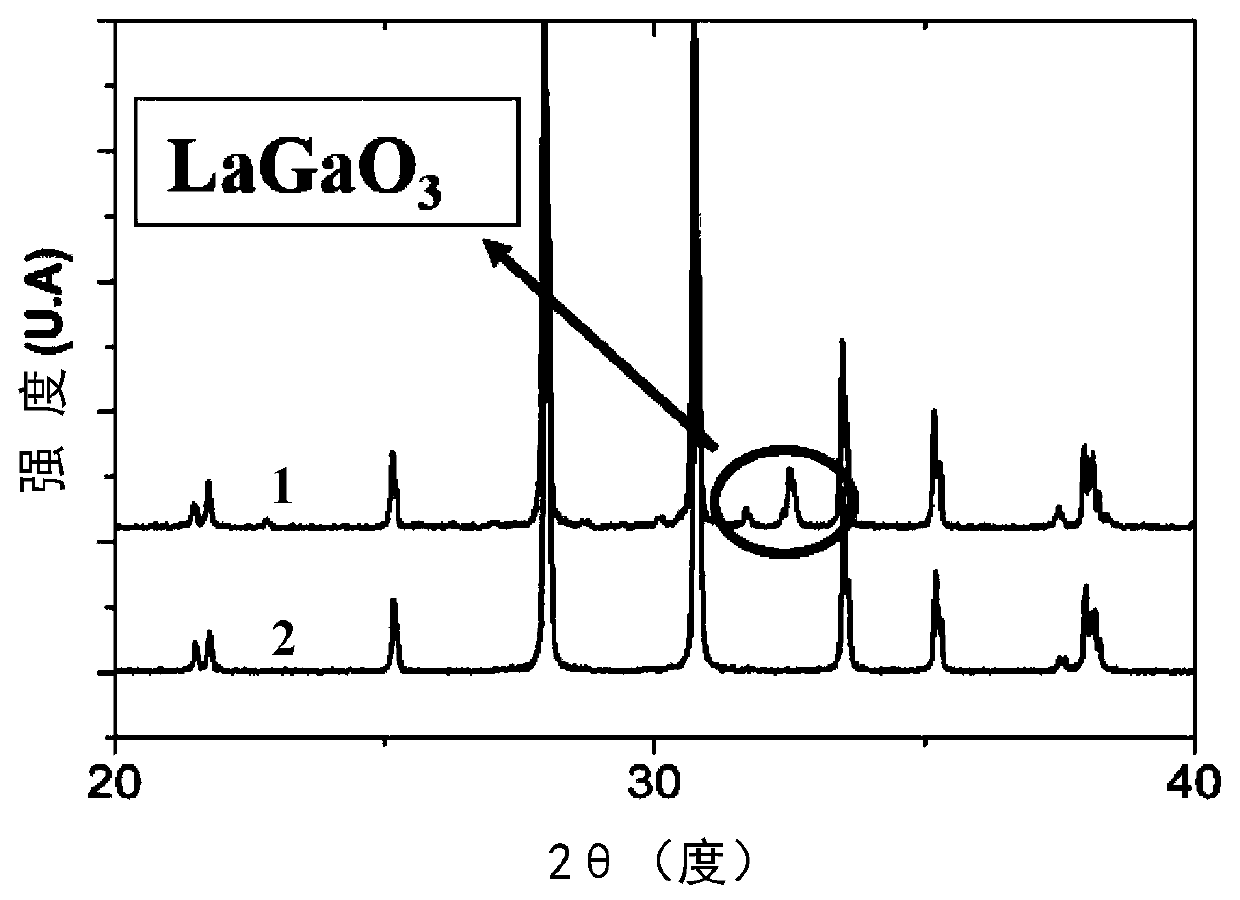

Embodiment 1

[0040] High purity La 2 o 3 , Ga 2 o 3 and SiO 2 The molar ratio of the powder is 3:5(1+x):(1-y) ingredients (x=0~0.008, y=0~0.01), with alcohol and agate balls as the mixing medium, at 60 rpm Mixed by wet ball milling for 20 hours, then dried, isostatically pressed into a dense cylindrical block, and sintered at 1300°C for 15 hours. The obtained polycrystalline blocks were put into three platinum crucibles of Φ76.2×200mm respectively, the thickness of the crucible was 0.3mm, and the orientation seed crystal of Φ76.2×50mm was placed on the bottom of the crucible in advance, and placed in the descending furnace Position, the furnace temperature is controlled at 1510°C, the crucible drops at a rate of 0.4mm / h after the top of the seed crystal is melted and kept for 8 hours, and the furnace temperature is raised at a rate of 1.5°C / day. After 18 days of growth, all the raw materials crystallize and stop falling. The furnace temperature is slowly lowered to 400°C at a rate of...

Embodiment 2

[0042] High purity La 2 o 3 , Ga 2 o 3 and SiO 2 The molar ratio of the powder is 3:5(1+x):(1-y) ingredients (x=0~0.008, y=0~0.01), with alcohol and agate balls as the mixing medium, at 60 rpm Mixed by wet ball milling for 20 hours, then dried, isostatically pressed into a dense cylindrical block, and sintered at 1300°C for 15 hours. The obtained polycrystalline material blocks were put into three platinum crucibles of Φ76.2×200mm respectively, the thickness of the crucible was 0.3mm, and a Φ76.2×50mm The oriented seed crystal is placed in a proper position in the descending furnace, the furnace temperature is controlled at 1520°C, the top of the seed crystal is melted and kept for 5 hours, the crucible is lowered at a rate of 0.4mm / h, and the furnace temperature is raised at a rate of 1.5°C / day. After 18 days of growth, all raw materials crystallize and stop falling. The furnace temperature is slowly cooled to 400°C at a rate of 20°C / h, and then cooled to room temperatu...

Embodiment 3

[0044] High purity La 2 o 3 , Ga 2 o 3 and SiO 2 The molar ratio of the powder is 3:5(1+x):(1-y) ingredients (x=0~0.01, y=0~0.01), with alcohol and agate balls as the mixing medium, at 60 rpm Mixed by wet ball milling for 20 hours, then dried, isostatically pressed into a dense cylindrical block, and sintered at 1350°C for 10 hours. The obtained polycrystalline blocks were put into three platinum crucibles of Φ101.6×200mm respectively, the thickness of the crucible was 0.4mm, and the orientation seed crystal of Φ101.6×50mm was placed on the bottom of the crucible in advance, and placed in the descending furnace Position, the furnace temperature is controlled at 1510°C, the top of the seed crystal is melted and kept for 10 hours, the crucible is lowered at a rate of 0.35mm / h, and the furnace temperature is raised at a rate of 2°C / day. After 20 days of growth, all the raw materials crystallize and stop falling. The furnace temperature is slowly cooled to 400°C at a rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com