Preparation method of rare earth ion doped tungsten oxygen fluoride silicate up-converted luminescent glass

A technology of fluorooxytungsten silicate and luminescent glass is applied in the field of preparing rare earth ion-doped fluorooxytungsten silicate up-conversion luminescent glass, and achieves the effects of simple preparation method, low cost of raw materials and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Put silicon dioxide, aluminum oxide, tungsten oxide, calcium fluoride, titanium dioxide, ytterbium oxide and erbium oxide in a molar ratio of 50: 15: 10: 20: 5: 5: 0.5 into the mortar, mix well and pour in the crucible;

[0016] 2) Put the above-mentioned crucible containing batch materials into a high-temperature furnace, and o C / min heating rate to 1550 o C, heat preservation for 2 h to melt;

[0017] 3) Pour the molten liquid in step 2) on 300 o The copper plate of C is cooled to room temperature, and then at 620 o C annealed for 2 h to obtain rare earth ion-doped oxytungstofluoride up-conversion luminescent glass.

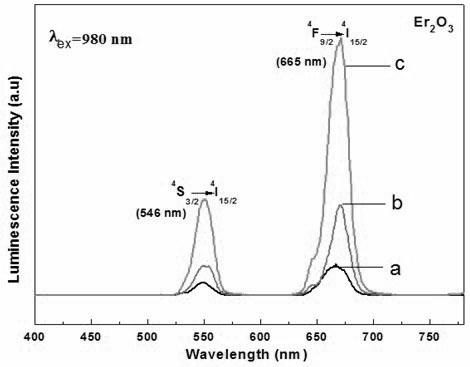

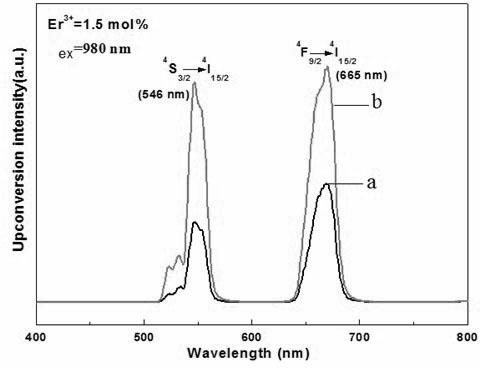

[0018] Figure 1 Curve a is the upconversion emission spectrum of the oxyfluoride tungsten silicate glass prepared in this example at an excitation wavelength of 980 nm. It can be seen from the figure that corresponding to Er 3+ ion: 4 S 3 / 2 → 4 I 15 / 2 and 4 f 9 / 2 → 4 I 15 / 2 Green (~546 nm) and red (~665 nm) upconversion emission with st...

Embodiment 2

[0021] 1) Put silicon dioxide, aluminum oxide, tungsten oxide, calcium fluoride, titanium dioxide, ytterbium oxide and erbium oxide in a molar ratio of 50: 15: 10: 20: 5: 5: 1.0 into the mortar, mix well and pour in the crucible;

[0022] 2) Put the above-mentioned crucible containing the batch material into the high temperature furnace, o C / min heating rate to 1550 o C, heat preservation for 2 h to melt;

[0023] 3) Pour the molten liquid in step 2) on 300 o C on the copper plate cooled to room temperature, and then at 640 o C annealed for 3 h to obtain rare earth ion-doped oxytungstofluoride up-conversion luminescent glass.

[0024] The up-conversion emission spectrum of the product is as figure 1 As shown in curve b, it can be seen from the figure that the prepared oxyfluorotungstic silicate glass obtained strong green (~546 nm) and red (~665 nm) upconversion emission at the excitation wavelength of 980 nm.

Embodiment 3

[0026] 1) Put silicon dioxide, aluminum oxide, tungsten oxide, calcium fluoride, titanium dioxide, ytterbium oxide and erbium oxide in a molar ratio of 50: 15: 10: 20: 5: 5: 1.5 into the mortar, mix well and pour in the crucible;

[0027] 2) Put the above-mentioned crucible containing batch materials into a high-temperature furnace, o C / min heating rate to 1550 o C, heat preservation for 2 h to melt;

[0028] 3) Pour the molten liquid in step 2) on 300 o C on the copper plate cooled to room temperature, and then at 650 o C annealed for 4 h to obtain rare earth ion-doped oxytungstofluoride up-conversion luminescent glass.

[0029] The upconversion emission spectrum of the product is shown in Figure 1, curve c. It can be seen from the figure that the prepared oxyfluorotungstic silicate glass obtained strong green light (~546 nm) and red light (~665 nm) at the excitation wavelength of 980 nm. nm) up-conversion emission, and the luminous intensity is stronger than that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com