Microwave short circuit ring

A short-circuit ring and microwave technology, which is applied in the field of short-circuit rings, can solve problems such as not being scratched by other objects, adverse effects on the health of operators, rubber vulcanization production and inconvenience to operators, so as to eliminate potential safety hazards and improve labor productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings by preferred embodiments:

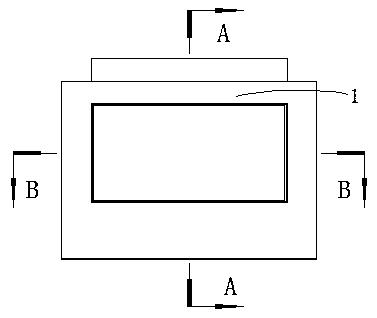

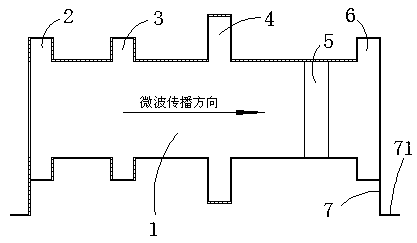

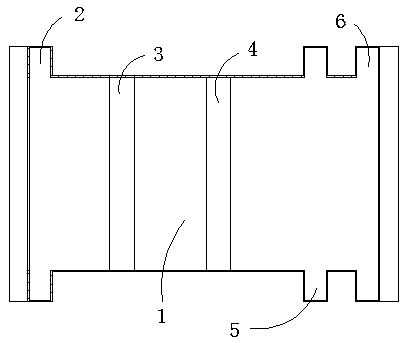

[0026] Embodiment: Because the rubber heating vulcanization production line generally all adopts the microwave of 2.45GHz, so a kind of microwave short circuit ring that the present invention provides, as figure 1 , Figure 4 As shown, including a hollow cavity 1, the cross section of the cavity 1 is rectangular, and the width of the cavity 1 cross section is greater than the height; as figure 2 , image 3 As shown, the inner wall of the cavity 1 is respectively provided with a first annular groove 2 and a second annular groove 6 at the ends of the first and last ends of the microwave propagation direction, and the widths of the first annular groove 2 and the second annular groove 6 are respectively 30 ± 1 mm, the depth of the first annular groove 2 and the second annular groove 6 is 30 ± 2 mm, the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com