Display device, array substrate and manufacturing method thereof

A technology of an array substrate and a manufacturing method, applied in the field of display devices, can solve the problems of low production efficiency, complex array substrate fabrication, increase of liquid crystal panels, etc., and achieve the effects of saving production costs, reducing production costs, and reducing etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

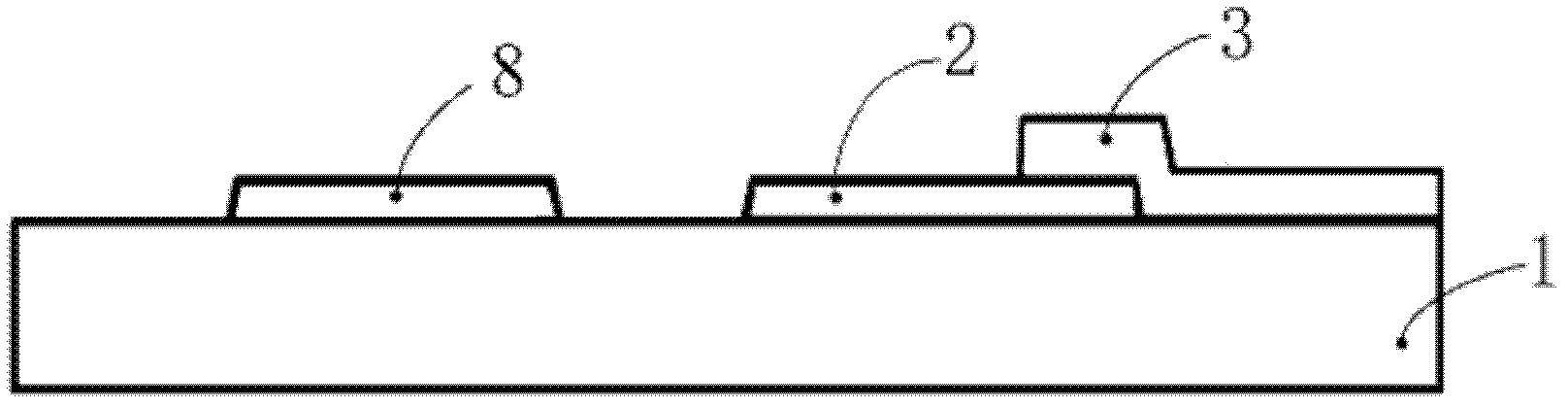

[0054] A specific implementation is as follows: reference Figure 2e , on the substrate after step S3, a gate metal thin film is deposited, and a gate electrode 6 is formed by using a common mask plate through masking, exposure, etching and photoresist removal processes, and the thickness of the gate electrode 6 is 2200 angstroms.

[0055] In order to better protect the devices on the array substrate, this embodiment may further include the following steps:

[0056] That is, step S5, forming a protective layer on the substrate after step S4 by adopting the fifth patterning process.

[0057] Specifically: reference Figure 2f , on the substrate after step S4, deposit a protective layer thin film, and use a common mask to form the protective layer 7 through masking, exposure, etching and photoresist removal processes.

[0058] In the embodiment of the present invention, the specific implementation of each step, especially the description about the method of forming the film la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com