Process for producing high capacity molybdenum dioxide/carbon cathode materials

A molybdenum dioxide and negative electrode material technology, applied in the field of lithium ion batteries, can solve the problems of applications that cannot meet industrial production, long heat treatment time, etc., and achieve the effects of high rate performance, high specific capacity, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, a cotton fiber fabric with a size of 20 mm×20 mm was soaked in an ethanol solution of phosphomolybdic acid with a concentration of 0.1 mM / ml, and stirred for 2 hours.

[0029] Then, it was dried at 60° C. for 5 minutes, and aged at 90° C. for 3 hours.

[0030] Finally in Ar / H 2 (preferably H 2 Accounting for 5% of the total volume) heat treatment at 500°C for 5 hours in a mixed atmosphere to obtain an ultrafine MoO 2 MoO with nanoparticles (2 / C nanostructured composites.

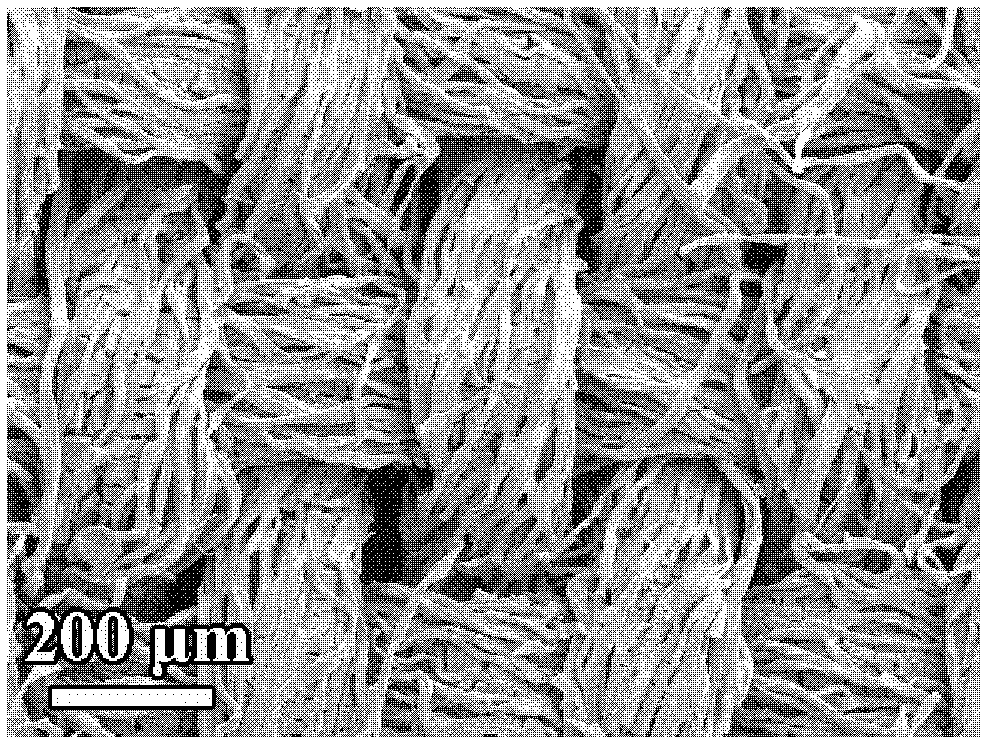

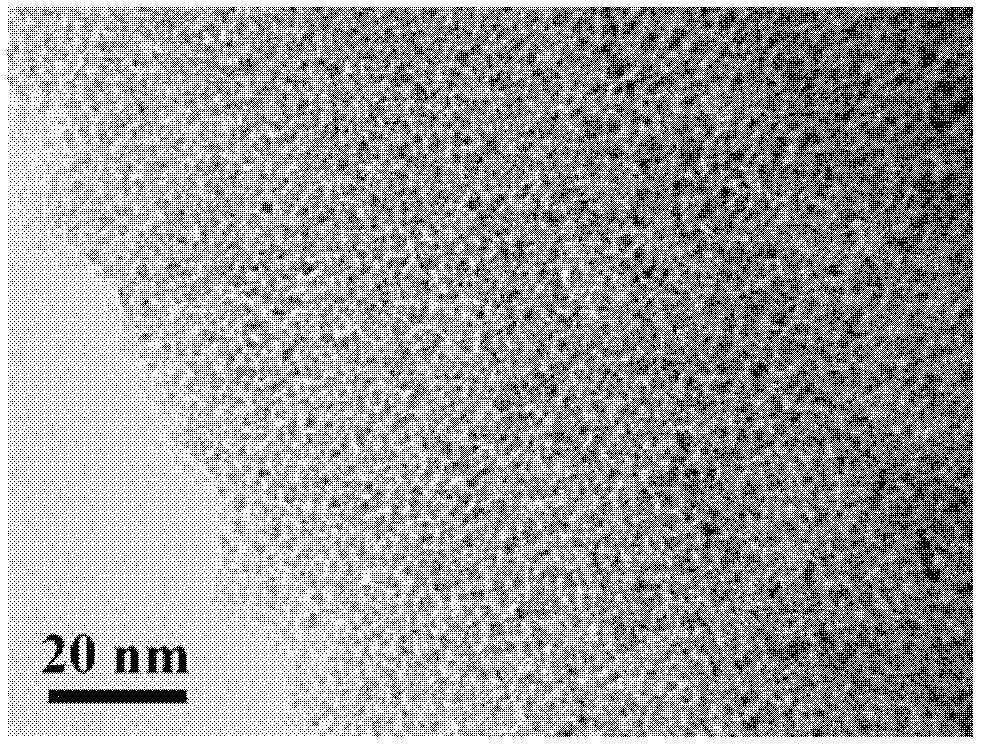

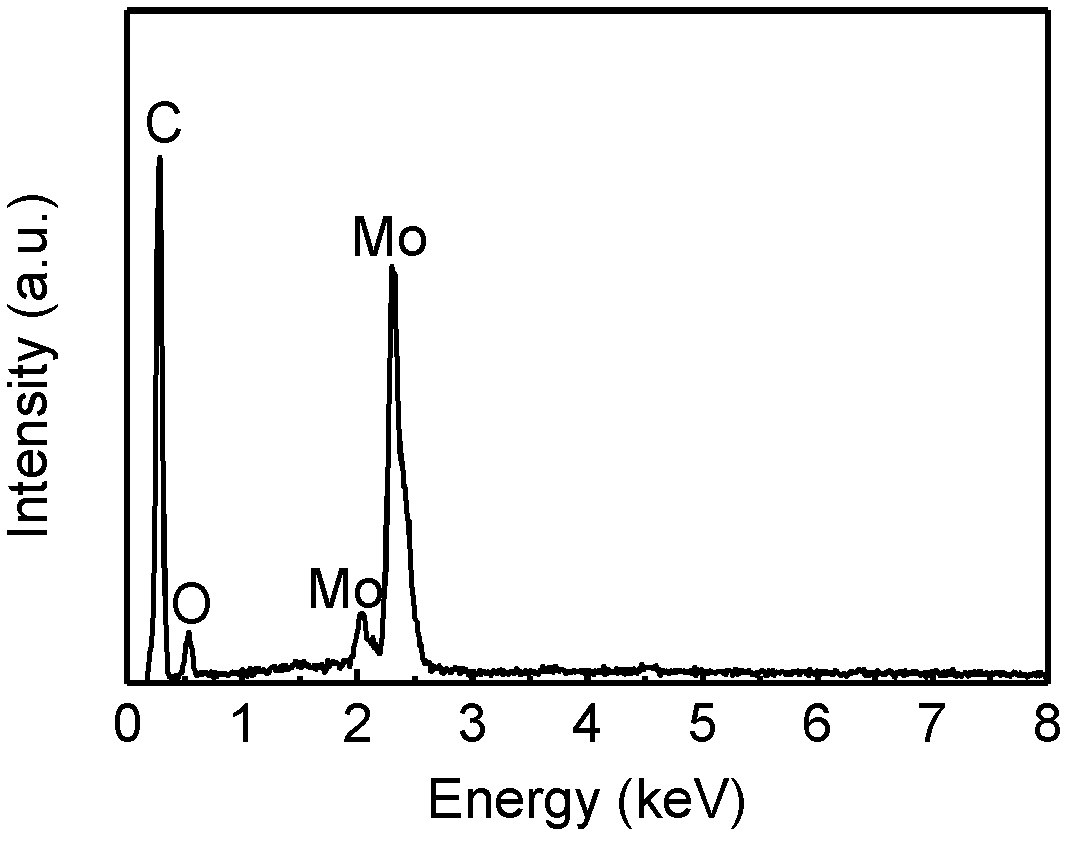

[0031] figure 1 It is the SEM figure of the product of the present invention, shows that the final product still keeps the initial appearance of cotton fiber fabric. figure 2 is a TEM image of the product of the present invention, illustrating that MoO 2 Nanoparticles ( image 3 It is the EDX figure of the product of the present invention, illustrates that the main component of the product of the present invention is MoO 2 and carbon.

[0032] The product obtained above is used as an el...

Embodiment 2

[0034] A cotton fiber fabric with a size of 20 mm×20 mm was soaked in an ethanol solution of phosphomolybdic acid with a concentration of 0.05 mM / ml, and stirred for 2 hours. Then, dry at 50°C for 30 minutes, then aging at 100°C for 6 hours, under Ar / H 2 (5%) heat treatment at 600°C for 5 hours in a mixed atmosphere to obtain MoO 2 / C composites, whose morphology is characterized by ultrafine MoO 2 The nanoparticles are uniformly distributed in the carbon matrix.

[0035] The above obtained MoO 2 The / C composite material was assembled into a button battery in the same manner as in Example 1, and the electrochemical performance was tested.

Embodiment 3

[0037] A cotton fiber fabric with a size of 20 mm×20 mm was soaked in an ethanol solution of phosphomolybdic acid with a concentration of 0.15 mM / ml, and stirred for 2 hours. Then, it was dried at 70° C. for 5 minutes, and then aged at 80° C. for 6 hours. in Ar / H 2 (5%) heat treatment at 550°C for 6 hours in a mixed atmosphere to obtain MoO 2 / C Composite.

[0038] The above obtained MoO 2 The / C composite material was assembled into a button battery in the same manner as in Example 1, and the electrochemical performance was tested.

[0039] In above-mentioned each embodiment, the size of cotton fiber fabric, the ethanol solution of phosphomolybdic acid are only exemplary, are not limited to on the above-mentioned consumption, generally speaking, the size of cotton fiber fabric can be selected according to specific circumstances, phosphorus molybdenum The ethanol solution of the acid is acceptable as long as it satisfies a certain range, such as 0.05-0.2mM / ml. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com