Method for preparing cuprous oxide film

A technology of cuprous oxide and thin film, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of low oxygen activity, poor crystal quality, and difficult precise control of the growth process, etc., to achieve optimal growth conditions , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 prepares high-quality Cu on ZnO single crystal substrate 2 O film

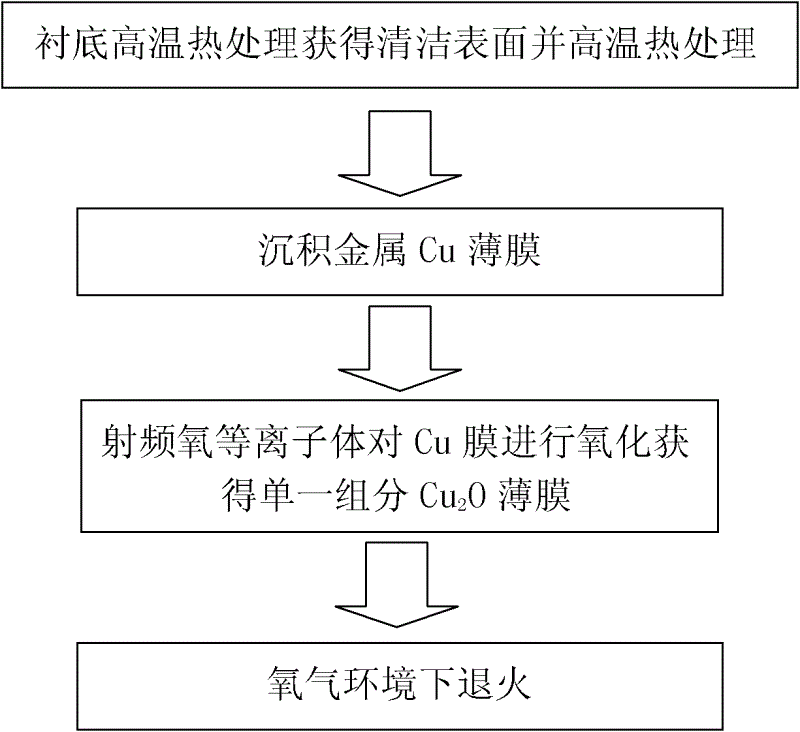

[0036] Such as figure 1 Shown process flow chart of the present invention, prepares high-quality Cu on zinc oxide single crystal substrate 2 The specific steps of O thin film are as follows:

[0037] 1) Remove the organic matter on the surface of the ZnO single crystal substrate by ultrasonic cleaning with acetone, alcohol, deionized water, etc., and then introduce the radio frequency plasma-assisted molecular beam epitaxy system (hereinafter referred to as the rf-MBE system);

[0038] 2) In an ultra-high vacuum environment, heat up to 750°C for 10 minutes of high-temperature heat treatment to remove surface-adsorbed inorganic impurities that cannot be removed by conventional cleaning;

[0039] 3) Perform radio frequency oxygen plasma treatment at the same temperature (750°C) for 10 minutes, the radio frequency power is 300W, and the oxygen flow rate is 2.0 sccm (cubic centimeters per mi...

Embodiment 2

[0048] Embodiment 2 prepares high-quality Cu on ZnO / sapphire (0001) single crystal substrate 2 O film

[0049] Such as figure 1 Shown process flow diagram of the present invention, prepares high-quality Cu on ZnO / sapphire (0001) single crystal substrate 2 The specific steps of O thin film are as follows:

[0050] 1) Plating molybdenum on the back of the commercially available sapphire substrate by magnetron sputtering, and ultrasonically cleaning with acetone, alcohol, and deionized water to remove organic matter on the substrate surface, and then introducing the substrate into the rf-MBE molecular beam epitaxy growth system ;

[0051] 2) deposit ZnO (0001) single crystal thin film on sapphire substrate with known method;

[0052] 3) The substrate is subjected to radio frequency oxygen plasma treatment at 500° C. for 10 minutes, with an oxygen flow rate of 2.0 sccm, to obtain a ZnO / sapphire (0001) template with an O-terminated surface;

[0053] 4) The substrate is heated ...

Embodiment 3

[0058] Example 3 on TiO 2 Preparation of High Quality Cu on Single Crystal Substrate 2 O film

[0059] Such as figure 1 Shown process flow diagram of the present invention, prepares high-quality Cu on titanium dioxide (rutile) single crystal substrate 2 The specific steps of O thin film are as follows:

[0060] 1) Plating molybdenum on the back of a commercially available rutile single crystal substrate by magnetron sputtering, and ultrasonically cleaning with acetone, alcohol, and deionized water to remove organic matter on the substrate surface, and then introducing the substrate into rf-MBE molecular beam epitaxy growth system;

[0061] 2) In an ultra-high vacuum environment, heat up to 900°C for 30 minutes of high-temperature heat treatment to remove impurities adsorbed on the surface;

[0062] 3) The substrate is cooled to 400° C., and subjected to radio frequency oxygen plasma treatment for 20 minutes. The radio frequency power is 340 W, and the oxygen flow rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com