Auxiliary reagent suitable for rapid electrorefining of high-silver alloyed gold

A technology of electrolytic refining and high-quality gold, which is applied in the direction of photography auxiliary technology, photography technology, instruments, etc., can solve the problems of environmental pollution, low production efficiency, long electrolysis cycle, etc., achieve significant environmental benefits, reduce consumption, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: Containing about 5% silver (m / m) alloy gold electrolysis

[0011] Select high-quality gold, which contains Au 93.5%, Ag 4.8%, Cu 0.56%, Ni 0.92%, Fe 0.13%, Pb 0.02%, Zn, As, Sb, Cr, Mn, Sn, Mg and other 12 elements Are less than 0.005%, electrolysis.

[0012] The weight of wool is 32Kg, converted into a pure weight of 29.8Kg, and the concentration of gold ions in the prepared electrolyte is 90-120g L -1 , hydrochloric acid concentration 1.5-2mol L -1 , the composition of the electrolytic auxiliary reagent QJ-D-1 is 1.0% NNO+19% NH 4 Cl+80%KCl, the concentration of gold electrolysis auxiliary reagent QJ-D-1 in the electrolyte is 80g L -1 , electrolyte temperature 45-55 ℃, electrolysis time 36h.

[0013] The specific steps of electrolysis are as follows:

[0014] Step 1: Preparation of Chlorauric Acid Solution

[0015] Use 5000-6000g of gold powder with a purity greater than 99.95%, put it in a double-layer glass reactor, and use 6mol L in a closed neg...

Embodiment 2

[0036] Embodiment Two: Electrolysis of Alloy Gold Containing About 7% Silver (m / m)

[0037] Select high-quality gold, which contains Au 92.1%, Ag 7.2%, Cu 0.46%, and the content of 15 elements such as Ni, Fe, Pb, Zn, As, Sb, Cr, Mn, Sn, Mg, etc. is all less than 0.005%. electrolysis. The specific steps of electrolysis are the same as in Example 1.

[0038] The weight of the input wool is 31.7Kg, converted into a pure weight of 29.20Kg, and the concentration of gold ions in the electrolyte is 90-120g L -1, hydrochloric acid concentration 1.5-2mol L -1 , the composition of the electrolytic auxiliary reagent QJ-D-1 is 2.0% NNO+43% NH 4 Cl+55% KCl, the concentration of gold electrolysis auxiliary reagent QJ-D-1 in the electrolyte is 100g L -1 , electrolyte temperature 45-55 ℃, electrolysis time 38h.

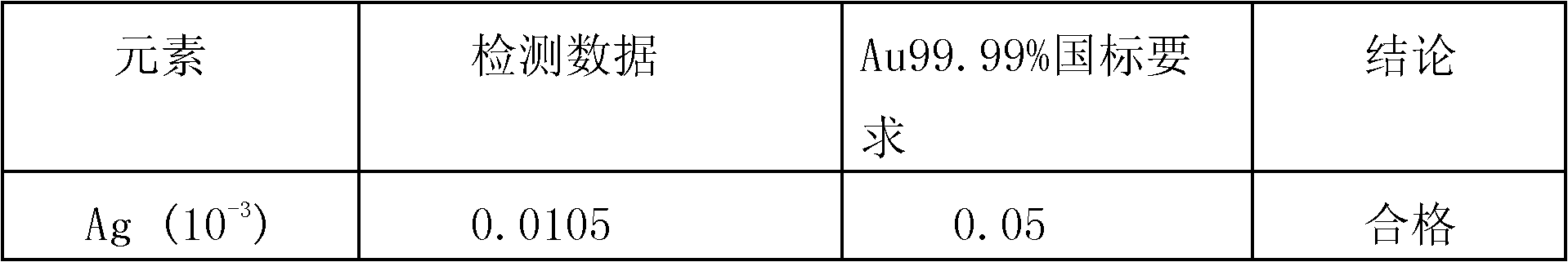

[0039] The data obtained by electrolysis are as follows: 20.92Kg of pure gold meeting the requirements of the Au99.99% standard was obtained. The contents of various impurity el...

Embodiment 3

[0043] Embodiment Three: Containing about 10% silver (m / m) alloy gold electrolysis

[0044] Select high-quality gold, which contains Au 89.82%, Ag 9.58%, Cu0.36%, Ni 0.15%, Fe, Pb, Zn, As, Sb, Cr, Mn, Sn, Mg and other 14 elements are all less than 0.005 % for electrolysis. The specific steps of electrolysis are the same as in Example 1.

[0045] The weight of the input wool is 30.12Kg, converted into a pure weight of 27.04Kg, and the concentration of gold ions in the electrolyte is 90-120g L -1 , hydrochloric acid concentration 1.5-2mol L -1 , the composition of the electrolytic auxiliary reagent QJ-D-1 is 3.0% NNO+52% NH 4 Cl+45% KCl, the concentration of gold electrolysis auxiliary reagent QJ-D-1 in the electrolyte is 120g L -1 , Electrolyte temperature 45-55 ℃, electrolysis time 40h.

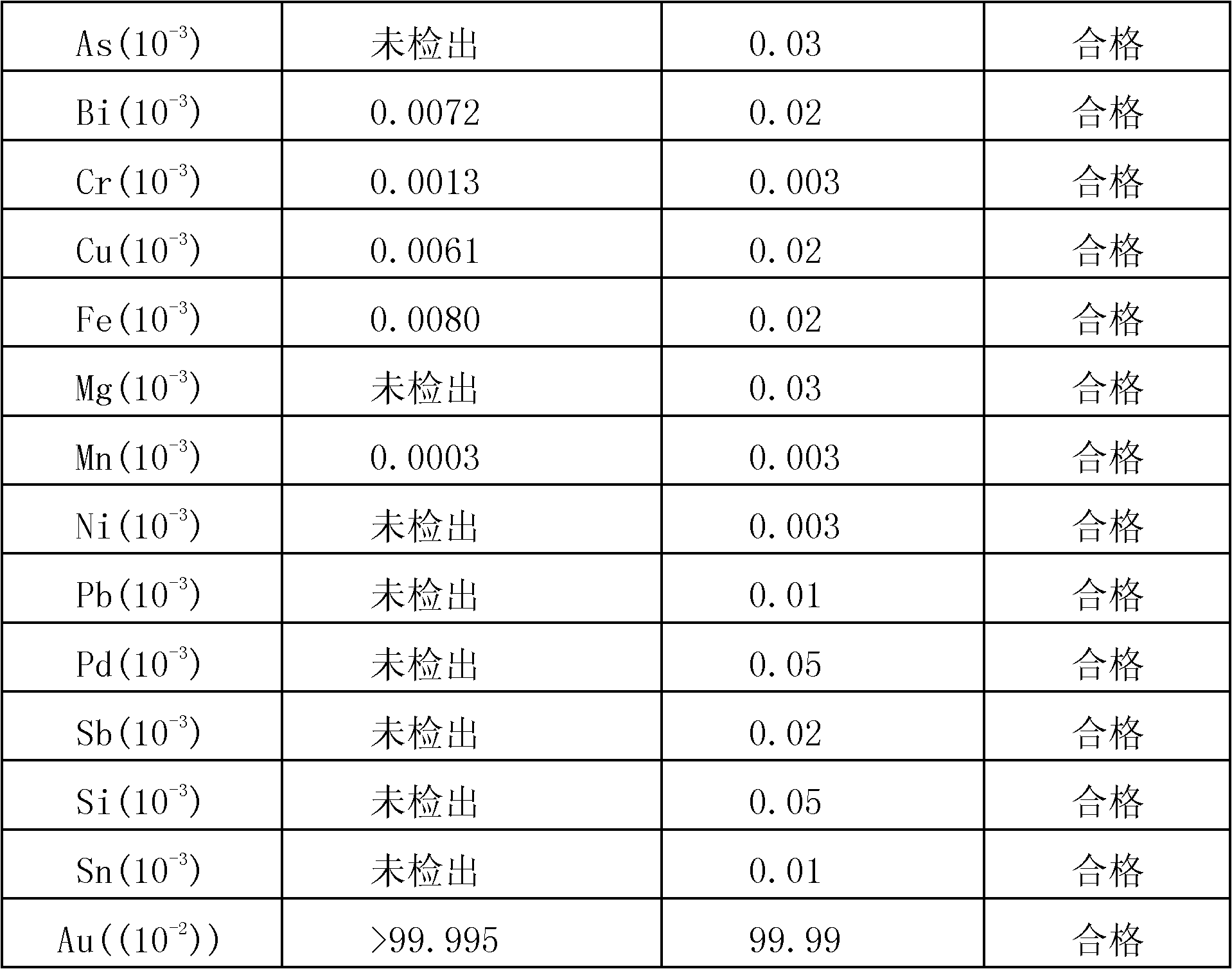

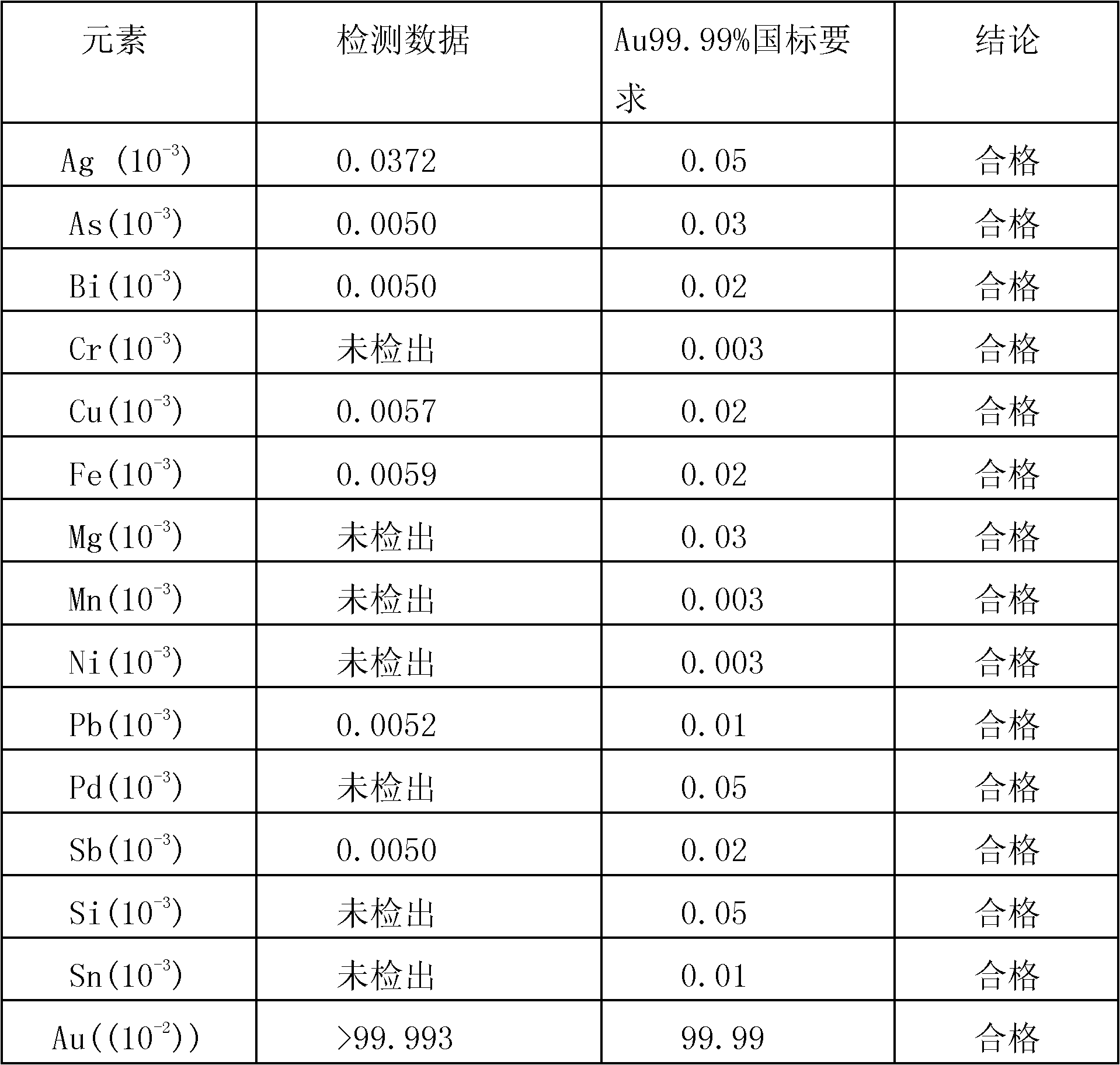

[0046] The data obtained by electrolysis are as follows: 18.51Kg of pure gold meeting the requirements of the Au99.95% standard was obtained. The content of each impurity element in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com