60kg-level low-cost and high-toughness steel plate and production method thereof

A low-cost, kilogram-level technology, applied in the field of high toughness steel plate and its manufacturing, can solve the problems of high preheating temperature, high welding cold crack sensitivity index, high welding processing cost, etc., and achieve excellent low temperature toughness, uniform and excellent strength and toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiments.

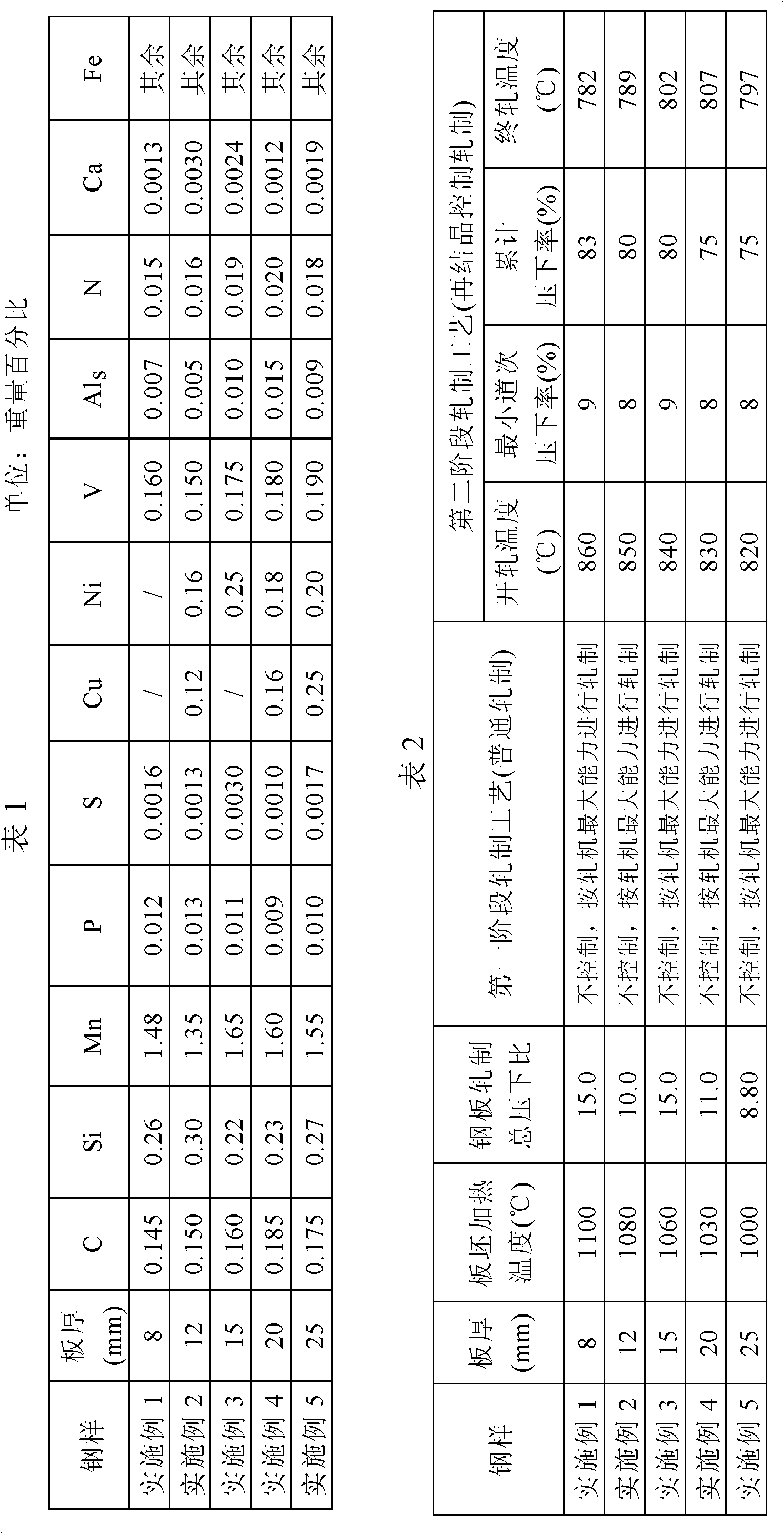

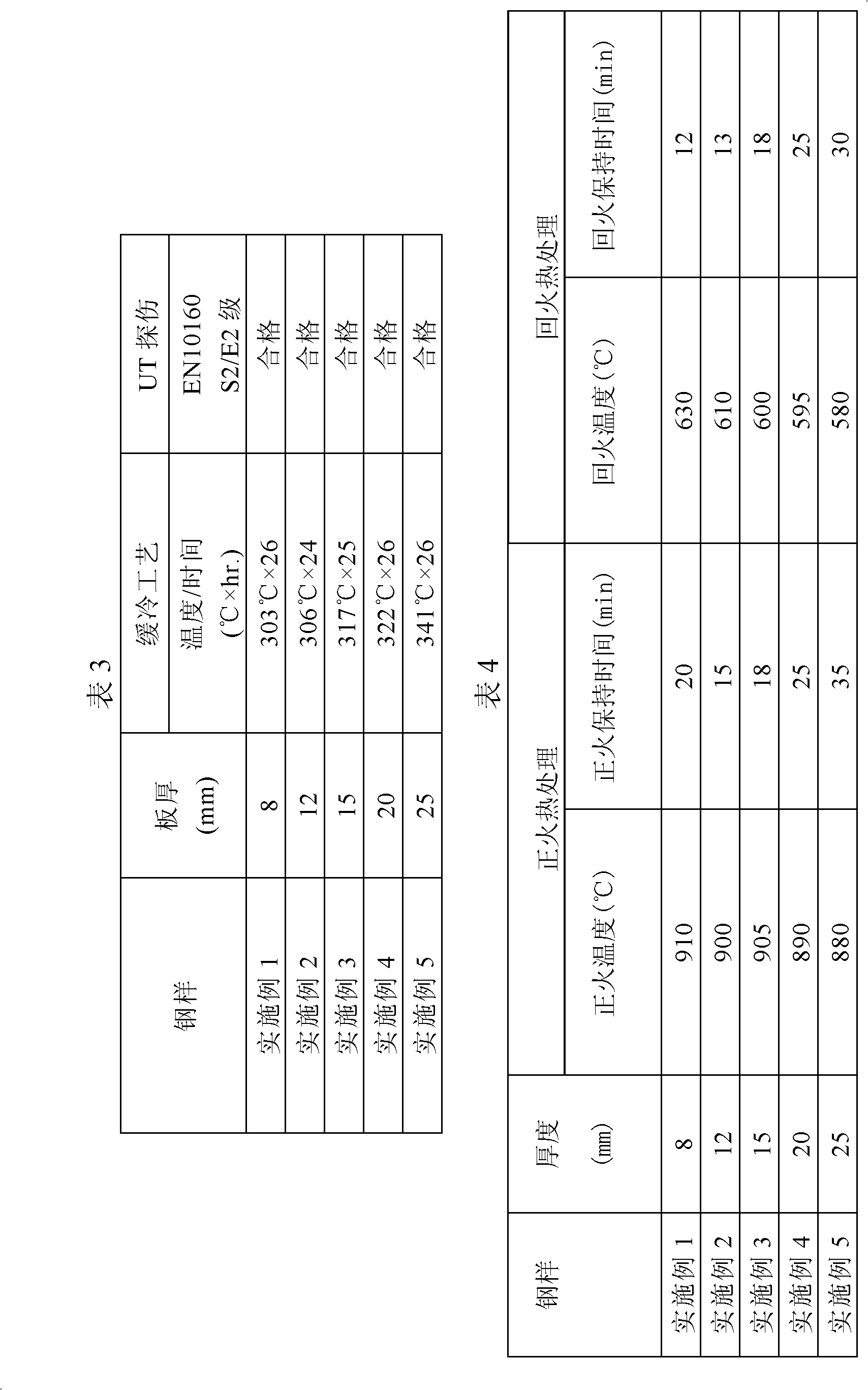

[0040] Table 1 is the composition of the steel in the embodiment of the invention, and Table 2, Table 3, and Table 4 are the manufacturing processes of the steel in the embodiment of the invention. Table 5 shows the properties of the steel in the example of the invention.

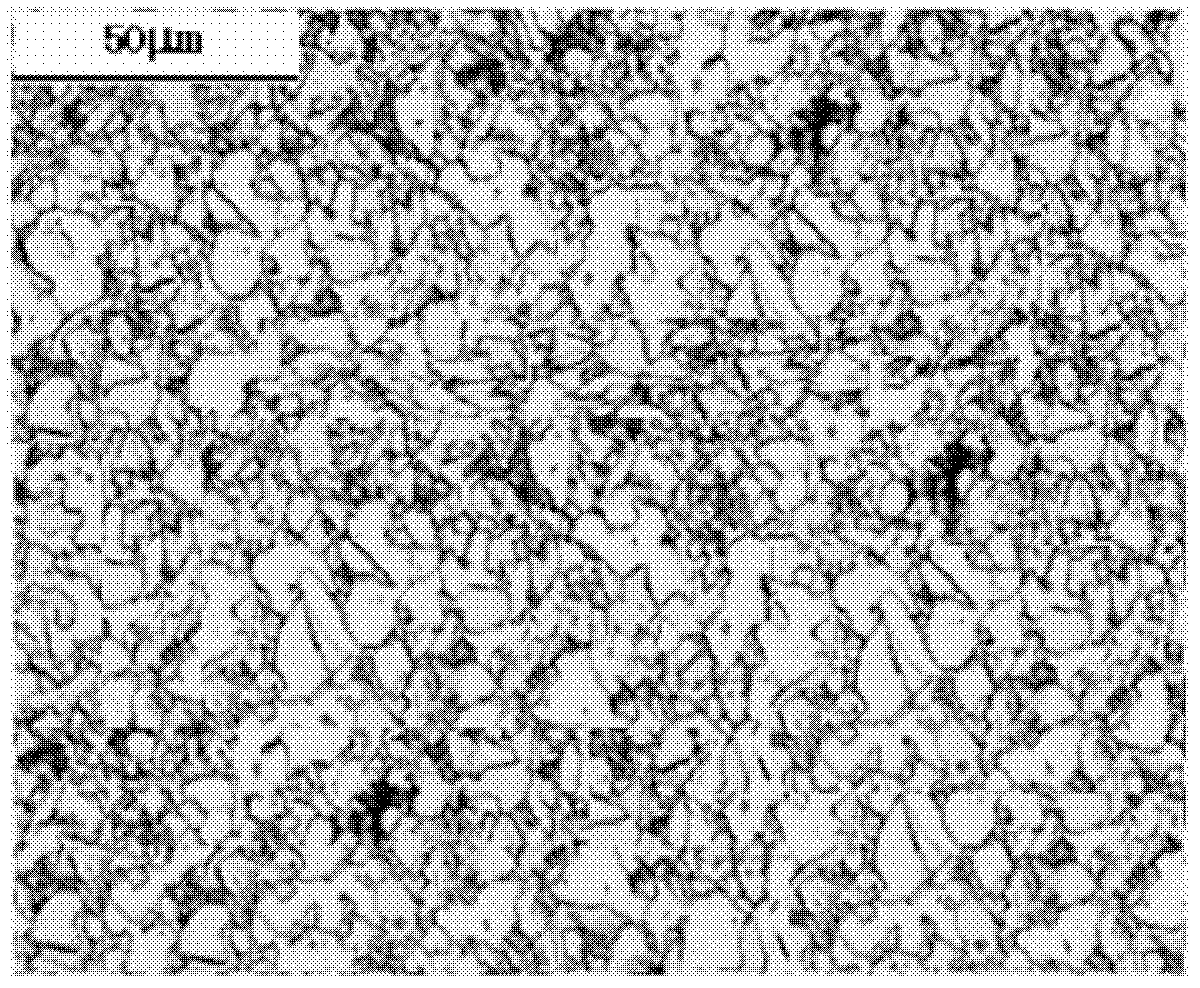

[0041] From figure 1 It can be seen from Table 5 that the microstructure of the steel plate of the present invention is uniform fine ferrite + pearlite + a small amount of granular bainite, and the average grain size of ferrite is below 15 μm, and uniform and excellent strength and toughness are obtained. While matching the strong plasticity, the steel plate has extremely excellent low temperature toughness.

[0042] In summary, the present invention uses the composition system of medium C-low Si-high Mn-ultra-low Als-high V alloying as the basis, optimizes the RCR+NT process, and makes the microstructure of the finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com