Method for preparing water-soluble azo dye continuously by chaos mixing of spiral tube

A technology of chaotic mixing and azo dyes, applied in the direction of mixing methods, azo dyes, monoazo dyes, etc., can solve the problems of unseen coupling and continuous reaction of spiral tube reactors, and achieve enhanced chaotic mixing effect and residence time Short, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of coupling component solution: in the 250ml flask that fills 20ml water, add 3.41g 1-amino-8-hydroxyl-3,6-naphthalene disulfonic acid, add the sodium carbonate solution that concentration is 20% under stirring, Adjust the pH to 6.0-6.5, add water to dilute the coupling component solution to a total volume of 200ml, and a pH of 6.0-6.5 to obtain a solution containing the coupling component of 1-amino-8-hydroxy-3,6-naphthalene disulfonic acid for use. Prepare an aniline diazonium salt solution with the same molar concentration as the coupling component solution for later use.

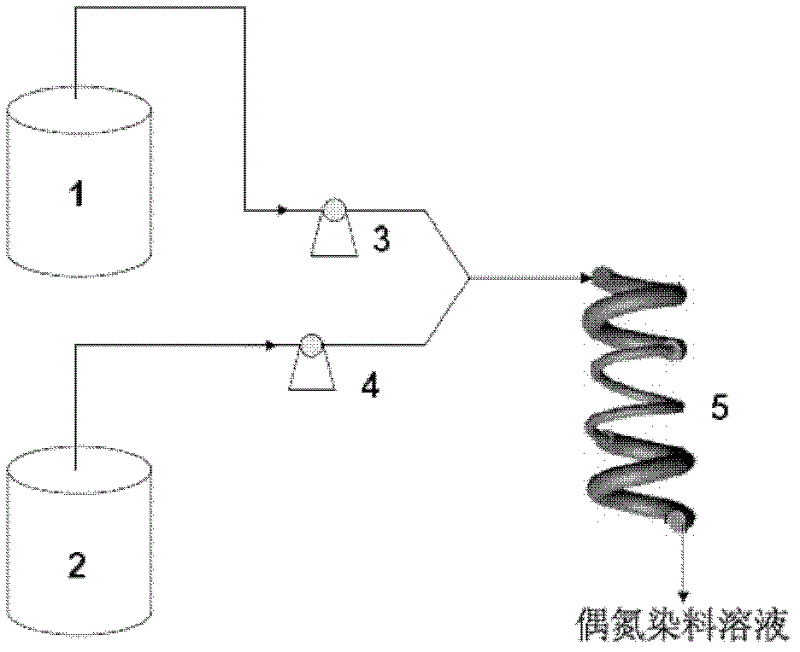

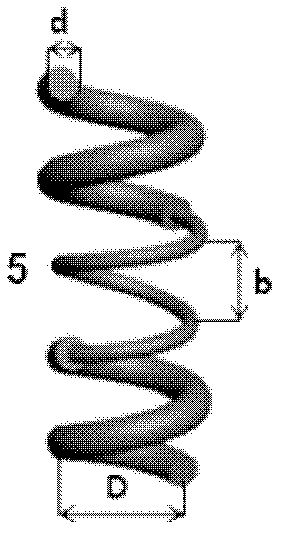

[0021] Utilize the calibration constant flow pump, the flow rate of regulating aniline diazonium salt solution and coupling component solution is 30ml / min, aniline diazonium salt solution and above-mentioned coupling component solution are transported respectively in the helical tube chaos continuous reactor (the The number of connections between the thick spiral tube and the thin ...

Embodiment 2-22

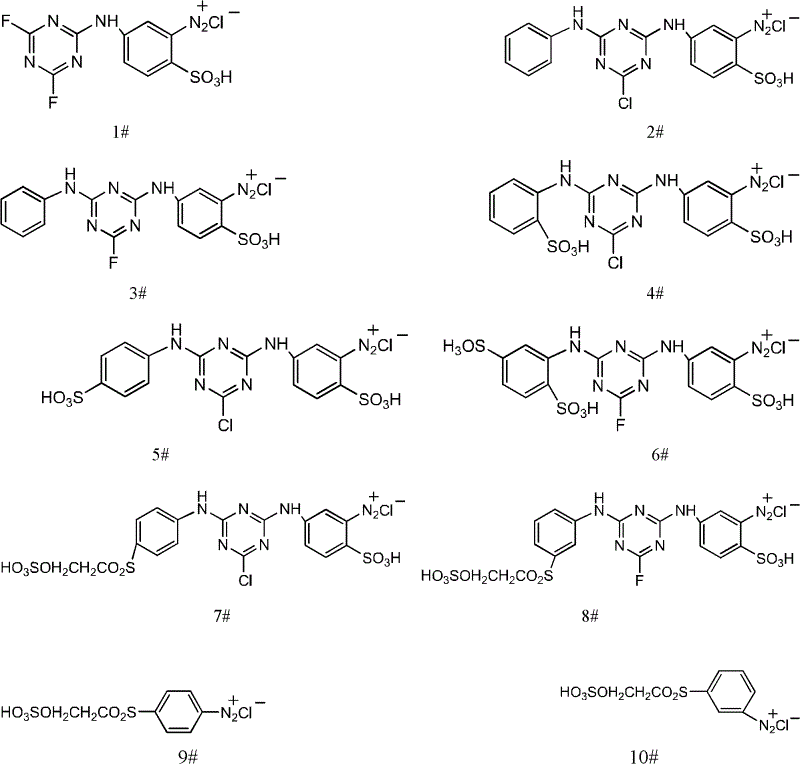

[0023] Use p-methoxyaniline diazonium salt solution, o-chloroaniline diazonium salt solution, 1-naphthylamine diazonium salt solution, aniline 2,5 disulfonic acid diazonium salt solution, p-nitroaniline diazonium salt solution, m- Nitroaniline diazonium salt solution, o-nitroaniline diazonium salt solution, p-cyanoaniline diazonium salt solution, p-aminobenzenesulfonic acid diazonium salt solution, o-aminobenzenesulfonic acid diazonium salt solution, 1-amino- 4-Naphthalenesulfonic acid diazonium salt solution and structure are respectively the diazonium salt solution of 1-10#, replaces aniline diazonium salt solution, respectively with 1-amino-8-hydroxyl-3 , 6-naphthalene disulfonic acid solution reaction to prepare the corresponding water-soluble azo dye solution, other conditions are consistent with Example 1.

[0024]

Embodiment 23-33

[0026] With 1-naphthylamine-6-sulfonic acid, 2-amino-8-hydroxy-6-naphthalenesulfonic acid, 2-amino-5-hydroxy-7-naphthalenesulfonic acid, 2-amino-8-hydroxy-3,6 -Naphthalene disulfonic acid, 1-amino-8-hydroxy-4-naphthalenesulfonic acid, 1-amino-8-hydroxy-2,4-naphthalene disulfonic acid, 1-anilino-8-naphthalenesulfonic acid solution and structure The coupling component solutions of 11-14# respectively replace 1-amino-8-hydroxyl-3,6-naphthalene disulfonic acid solution, and react with aniline diazonium salt solution in a spiral tube chaotic continuous reactor to obtain the corresponding The water-soluble azo dye solution, other conditions are consistent with embodiment 1.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com