A kind of polyurethane foam with rice husk as raw material and preparation method thereof

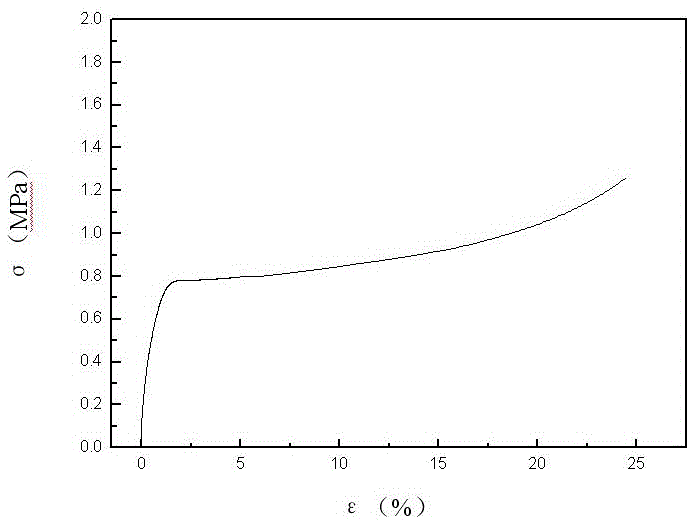

A technology of foamed plastics and polyurethane, applied in the field of polyurethane foamed plastics and its preparation, to achieve the effects of simplifying the liquefaction process, excellent cushioning and energy absorption performance, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 60-mesh rice husk powder, puff it through microwave irradiation, and treat it in an oven at 110°C to 130°C for 2 hours;

[0040] Add 80 parts of polyethylene glycol with a molecular weight of 400, 10 parts of ethylene glycol, 10 parts of glycerin, and 0.25 parts of Tween-80 into the reaction vessel, and then add 25 parts of rice husk powder with a particle size of 60 meshes. Heat up to 190°C at a stirring speed of 300rpm, then slowly add 3 parts of concentrated sulfuric acid dropwise within 5min, react for 100min, stop heating, take out the reaction kettle, and then put the crude rice husk liquefaction product in the above reaction kettle in a vacuum oven at 110℃ Vacuum drying was carried out for 24 hours to obtain rice husk liquefaction, the mass percentage of water was 0.497% after testing, and the contained water could be used as foaming agent.

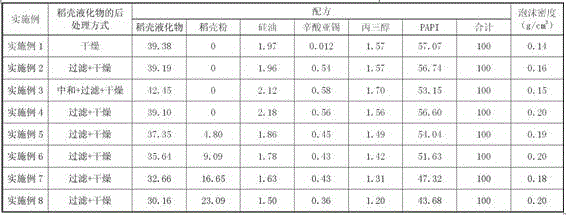

[0041]Take 42.45 parts of the above-mentioned rice husk liquefied product, then add 2.12 parts of silicone oil AK8807...

Embodiment 2

[0043] The rest of this example is the same as that of Example 1, the difference is: filter the crude rice husk liquefaction product with 2 layers of gauze, then filter the liquid substance with fast filter paper, and then put the liquid product into a vacuum oven at 110°C for vacuum After drying for 24 hours, the liquefied rice husk was obtained. Take 39.19 parts of the above-mentioned rice husk liquefaction, then add 1.96 parts of silicone oil AK8807, 0.54 parts of stannous octoate and 1.57 parts of glycerin, stir it under the mixer at a speed of 500 rpm for 3 minutes to form a resin mixture, adjust the temperature of the resin mixture to 25°C, and then add 56.74 parts of PAPI with a temperature of 25°C to prepare a density of 0.16g / cm 3 rigid polyurethane foam.

Embodiment 3

[0045] Others of this embodiment are the same as those of Example 1, the difference being that first the crude product of rice husk liquefaction is treated with 2mol / L of NaHCO 3 Aqueous solution neutralization treatment, stop dropping when the pH of the liquefied product is 7.0, then filter the neutralized liquefied product with gauze once, then filter the liquid material with fast filter paper, and finally put the liquid product in a vacuum oven at 110°C vacuum drying for 48 hours to obtain rice husk liquefaction. Take 39.38 parts of the rice husk liquefaction, then add 1.97 parts of silicone oil AK8807, 0.012 parts of stannous octoate and 1.57 parts of glycerol, stir it under the mixer at a speed of 500 rpm for 3 minutes to form a resin mixture, adjust the temperature of the resin mixture to 25°C, and then add 57.07 parts of PAPI with a temperature of 25°C to prepare a density of 0.15g / cm 3 rigid polyurethane foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com