Method and system for mixed refrigerant gas-liquid split throttling refrigeration

A mixed refrigerant and split-flow technology, which is applied in refrigeration and liquefaction, cold treatment separation, liquefaction, etc., can solve high-cost problems that can only be used in a small number of small-scale liquefaction devices and offshore floating liquefaction devices, and achieve low operating costs and low investment. Energy saving and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

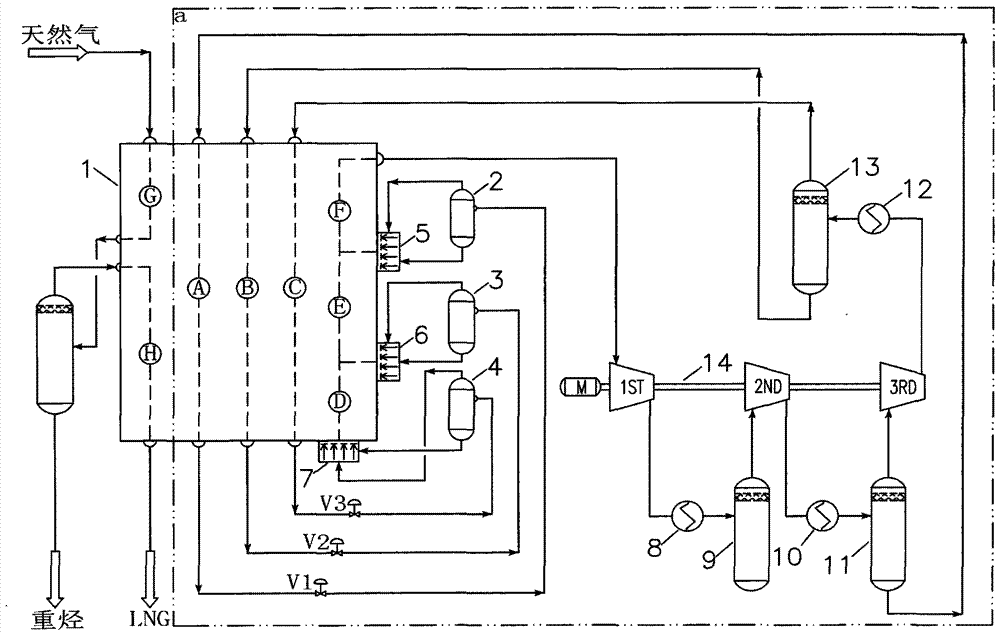

[0036] For the specific process flow of this embodiment, please refer to figure 1 .

[0037]A mixed refrigerant gas-liquid split throttling refrigeration system, comprising: a mixed refrigerant compressor 14, a first-stage outlet cooler 8, a second-stage inlet buffer tank 9, a second-stage outlet cooler 10, and a third-stage inlet separator 11 , three-stage outlet cooler 12, three-stage outlet separator 13, the first flow channel A, the second flow channel B, the third flow channel C, the fourth flow channel D, the fifth flow channel E, and the sixth flow channel of the cold box 1 Channel F, first separator 2, second separator 3, third separator 4, first throttle valve V1, second throttle valve V2, third throttle valve V3, first static mixer 5, The second static mixer 6 and the third static mixer 7, wherein the inlet of the first section of the mixed refrigerant compressor 14 is connected to the outlet of the sixth channel F of the cold box 1, and the outlet is followed by th...

Embodiment 2

[0041] For the specific process flow of this embodiment, please refer to figure 1 .

[0042] As shown in the device, the first-stage outlet cooler 8, the second-stage outlet cooler 10 and the third-stage outlet cooler 12 are air coolers, and the mixed refrigerant compressor 7 is a centrifugal compressor.

[0043] The low-pressure mixed refrigerant I from the cold box enters the first stage of the mixed refrigerant compressor 14 at a flow rate of 171920kg / h to be compressed and boosted to 1000kPa, and then cooled to 45°C through the first-stage outlet cooler 8 to obtain the mixed refrigerant II; the mixed refrigerant Agent II enters the mixed refrigerant compressor 14 through the second-stage inlet buffer tank 9 to be compressed and pressurized to 2400kPa in the second-stage, and then is cooled to 45°C through the second-stage outlet cooler 10 and sent to the third-stage inlet separator 11, and the liquid is obtained after separation. Phase mixed refrigerant III and gas phase ...

Embodiment 3

[0046] For the specific process flow of this embodiment, please refer to figure 1 .

[0047] As shown in the figure, the first-stage outlet cooler 8 and the second-stage outlet cooler 10 are air coolers, the third-stage outlet cooler 12 is a shell-and-tube heat exchanger, and the mixed refrigerant compressor 7 is a screw compressor.

[0048] The low-pressure mixed refrigerant I from the cold box enters the first stage of the mixed refrigerant compressor 14 at a flow rate of 17200kg / h to be compressed and boosted to 400kPa, and then cooled to 40°C through the first-stage outlet cooler 8 to obtain the mixed refrigerant II; the mixed refrigerant Agent II enters the mixed refrigerant compressor 14 through the second-stage inlet buffer tank 9 to be compressed and pressurized to 900kPa in the second stage, and then is cooled to 40°C through the second-stage outlet cooler 10 and sent to the third-stage inlet separator 11, and the liquid is obtained after separation. Phase mixed refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com