Oriented solidification casting method and apparatus

A directional solidification and mold technology, applied in the field of casting, can solve the problems of inability to judge the dynamic position, part shape and size restrictions, and no information collection system, etc. It is suitable for mass production, large temperature gradient, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

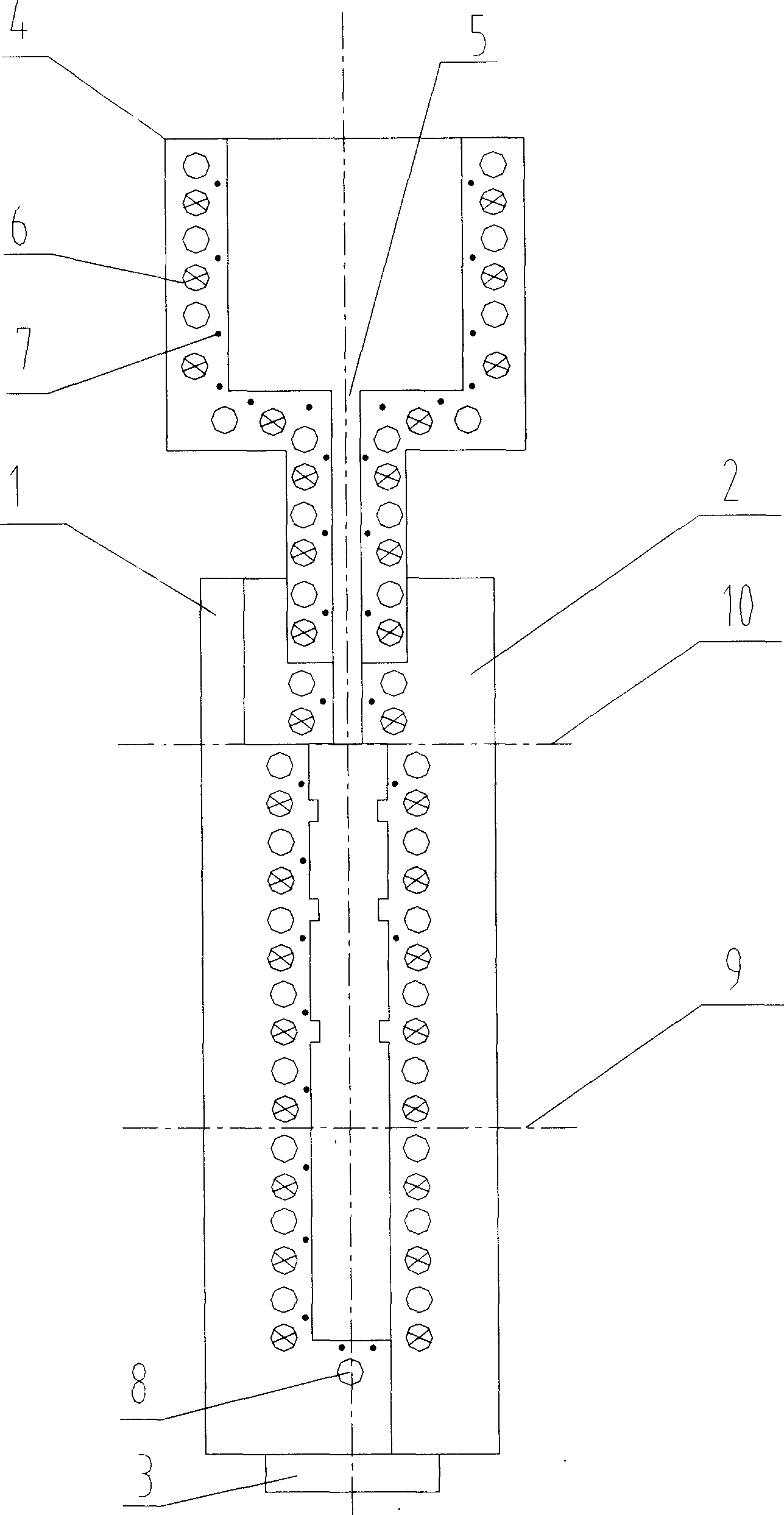

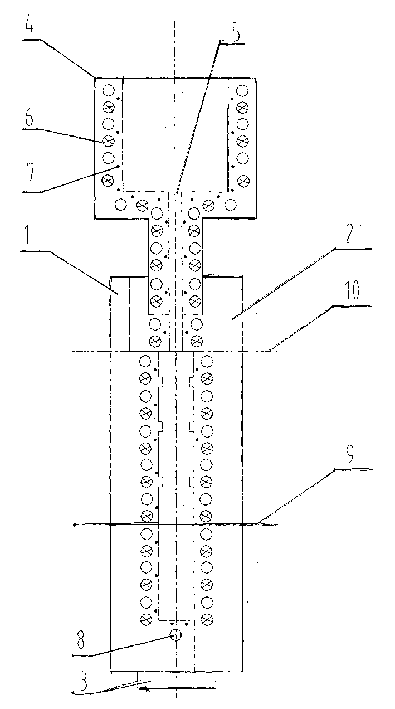

[0025] What is to be prepared in this embodiment is the directionally solidified thin plate casting with ribs. The mold used is as figure 1 shown in figure 1 Among them, the module 1 and the module 2 are locked by the locking buckle 3, and they are combined into a mold. The lower end of the riser 4 is inserted into the mold, and the riser 4 is provided with a liquid material input port 5, and the mold wall and the riser 4 Hollow cooling passages 8 and heating elements 6 are arranged alternately in the walls. The hollow cooling passages 8 are connected to the coolant supply components through control valves. The heating elements 6 are connected to the power supply through switches. The control valves and switches are connected to the control parts. connection, the mold is provided with a temperature sensor 7, and the temperature sensor 7 is closely attached to a position close to the mold wall of the cavity.

[0026] The preparation process of this directionally solidified th...

Embodiment 2

[0028] Present embodiment is identical with embodiment 1 except following process: figure 1 A sealing cover is arranged on the middle riser 4 to seal the riser 4, and then compressed gas is injected into the riser 4, and a compressive stress of 1.5 MPa is applied to the aluminum alloy liquid surface in the riser 4 through the gas.

Embodiment 3

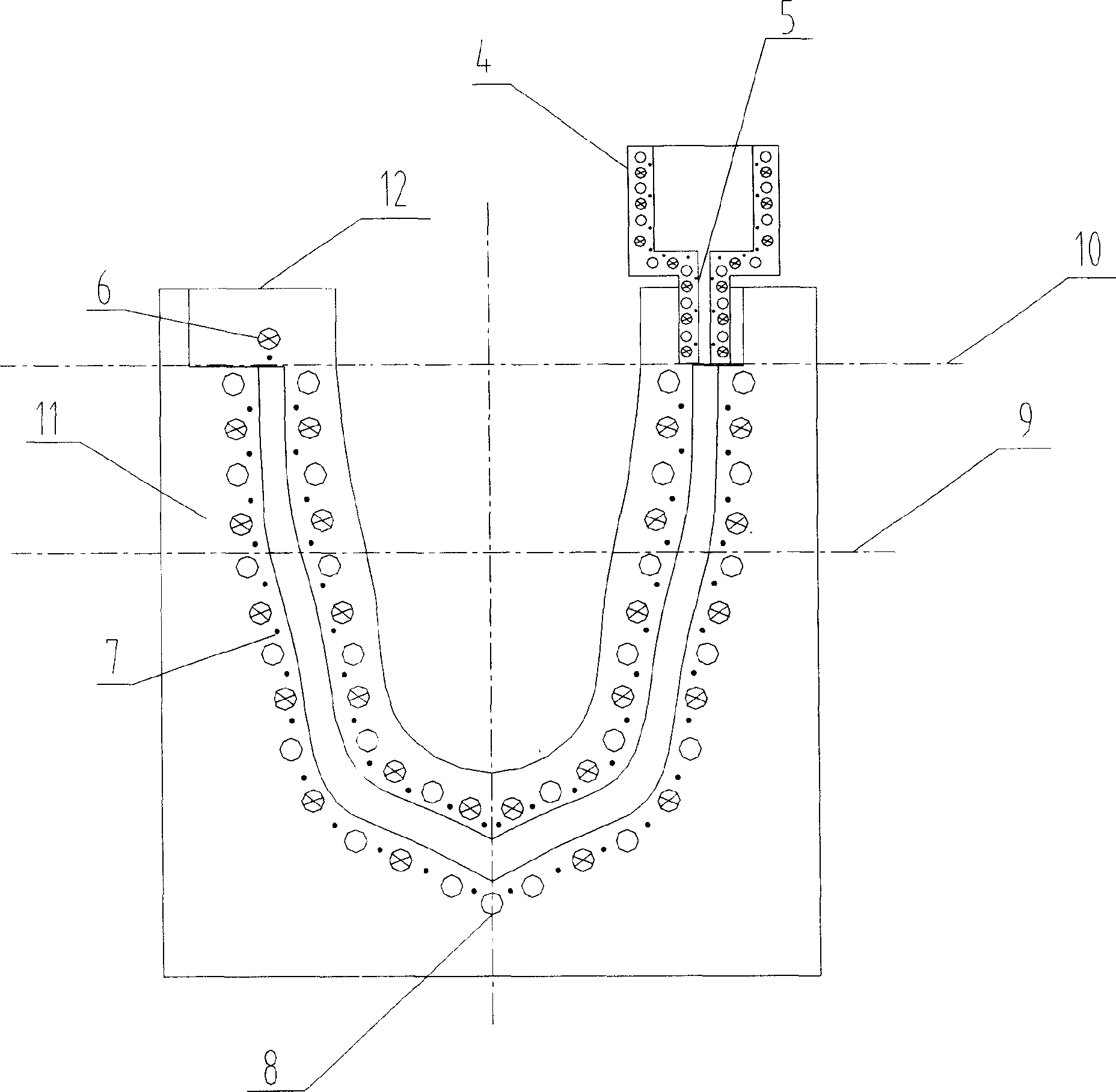

[0030] What this embodiment is to prepare is a directionally solidified shell-shaped casting. The mold used is as figure 2 shown in figure 2 Among them, the module 11 and the module 12 are locked by screws to form a mold, the riser 4 is inserted into one end of the mold, and the riser 4 is provided with a liquid material input port 5, which is in the wall of the mold and the wall of the riser 4 Hollow cooling passages 8 and heating elements 6 are arranged alternately. The hollow cooling passages 8 are connected to the coolant supply components through control valves. The heating elements 6 are connected to the power supply through switches. The control valves and switches are connected to the control parts. A temperature sensor 7 is arranged in the middle, and the temperature sensor 7 is closely attached to a position close to the mold wall of the cavity.

[0031] The preparation process of this directionally solidified shell-shaped casting is specifically as follows: firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com