Trap lamp with combined light sources and preparation method thereof

A technology of combining light source and trapping lamp, applied in the direction of light source, light source combination, light source fixing, etc., can solve the problems of high energy consumption, short lifespan, trapping and so on of ultraviolet fluorescent lamps, and achieves reduction of light shielding effect, improvement of lifespan, and expansion of the spectral range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

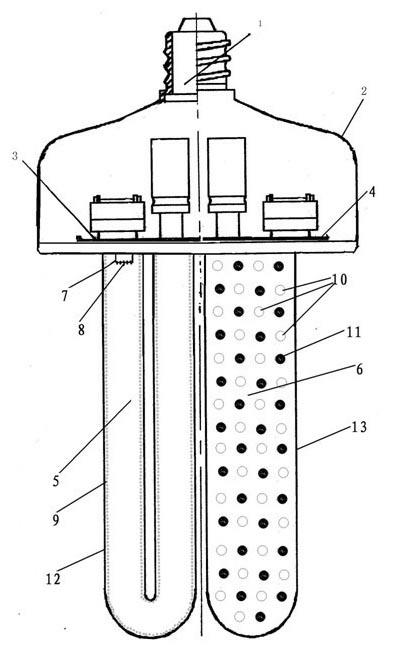

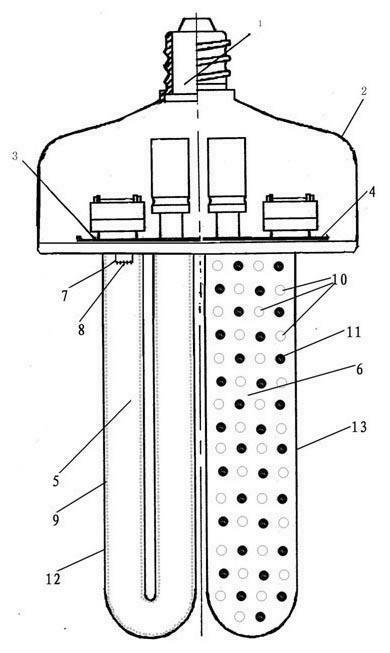

[0020] Such as figure 1 As shown, the present invention is made up of lamp cap 1, lamp holder 2, fluorescent lamp ballast 3, LED driving power supply 4, fluorescent lamp tube 5 and LED lamp tube 6; described fluorescent lamp tube 5 is made of glass tube 12 coated with fluorescent powder 9 1. A cathode filament 7 coated with an electron powder slurry 8 as an electron emission material;

[0021] The phosphor 9 is a mixture of phosphors with a peak wavelength of 330nm and 370nm, and its composition and the mass percentages of each component in the total phosphor are respectively 10-40% for 330nm phosphors and 60-90% for 370nm phosphors. %.

[0022] The shape of the fluorescent tube 5 is U-shaped, and the glass tube 12 is made of quartz.

[0023] The LED lamp tube 6 has a cylindrical appearance and is composed of green-emitting LED light sources 10 and blue-emitting LED light sources 11 that are evenly distributed in an interlaced manner. The peak wavelength of green light is 5...

Embodiment 2

[0032] A. Preparation of the phosphor layer: Weigh 20g of phosphor with a peak wavelength of 330nm, add 80g of phosphor with a peak wavelength of 370nm into a container with a mixer, add 55ml of deionized water, 75ml of binder, and 5g of reinforcing agent, turn on the mixer, Control the rotation speed at 160 rpm, stir for 6 hours, and control the density of the powder slurry to 1.45 g / cm3; apply the prepared phosphor to the inner wall of the glass tube 12, bake the coated glass tube 12, and bake the coated glass tube 12 at 500- Bake at 540°C for 10-30 minutes to prepare the glass tube 12 coated with the phosphor layer 6;

[0033] B. Preparation of the electronic powder slurry layer: Pour the electronic powder slurry into an automatic stirring container, put the cathode of the fluorescent lamp with the filament in the container containing the electronic powder slurry, and make the electron powder by electrophoresis or dip coating. The powder slurry is applied to the filament ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com