Terminal plugging mechanism of automatic assembling machine of electric connector

An automatic assembly machine and electrical connector technology, which is applied to the assembly/disassembly of contacts, etc., can solve the problems of high labor intensity for operators, large consumption of human resources, and high defective rate of electrical connectors, so as to improve the competitiveness of enterprises , low probability of safety hazards, and the effect of reducing the consumption of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

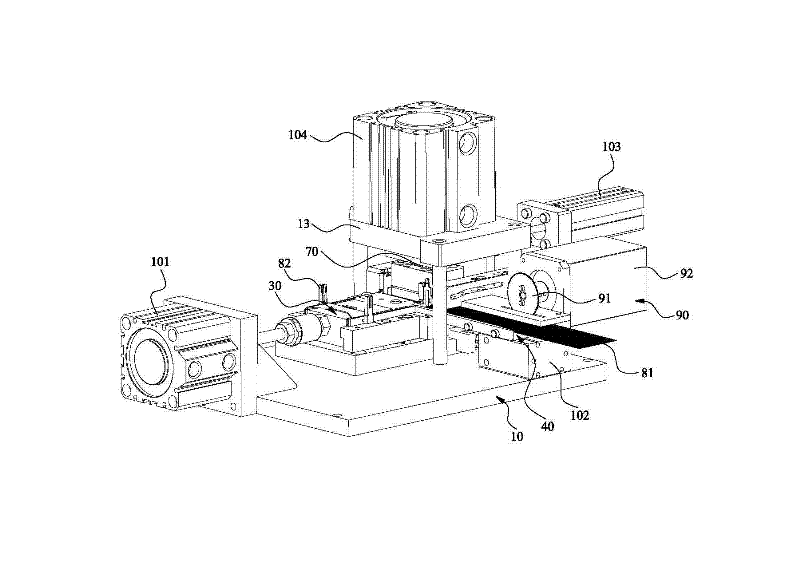

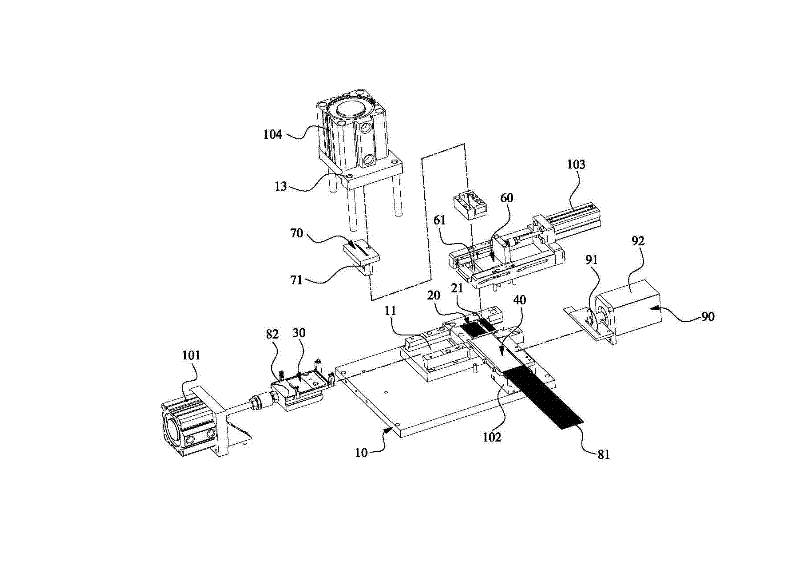

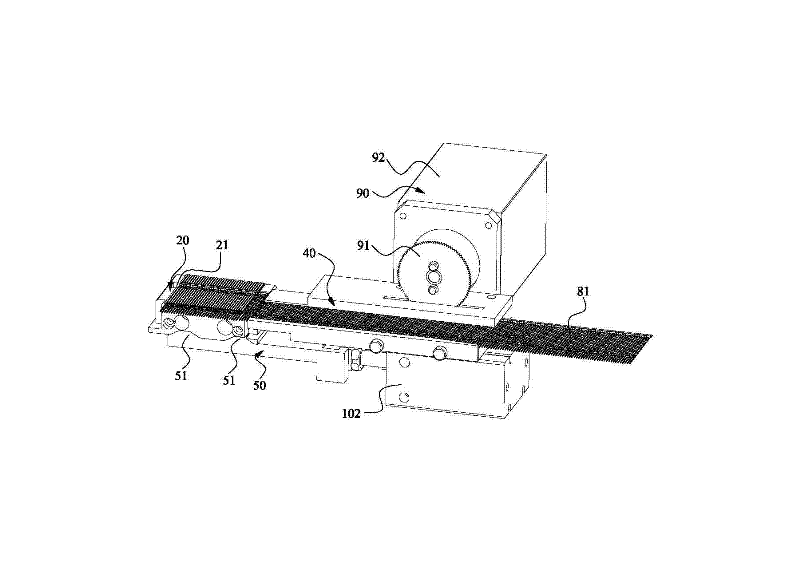

[0052] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a base 10 and a terminal positioning seat 20 that can be floated up and down on the base 10, and a plastic plastic is provided around the terminal positioning seat 20 Component positioning seat 30, terminal feed rail 40, lifting block 50, crimping terminal sliding cover 60 and punch 70.

[0053] Wherein, the base 10 is provided with a sliding slot 11 and a hollow slot 12 , and the sliding slot 11 is located at the front side of the hollow slot 12 .

[0054] The terminal positioning seat 20 is located above the aforementioned hollow groove 12, and the terminal positioning seat 20 is provided with a blanking groove 21 and a terminal groove 22 for positioning the terminal 81. The blanking groove 21 communicates with the aforementioned hollow groove 12, and the terminal groove 22 Protrusions 201 of different lengths that conflict w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com