Preparation method of transition metal doped alpha-Fe2O3 nano rod array

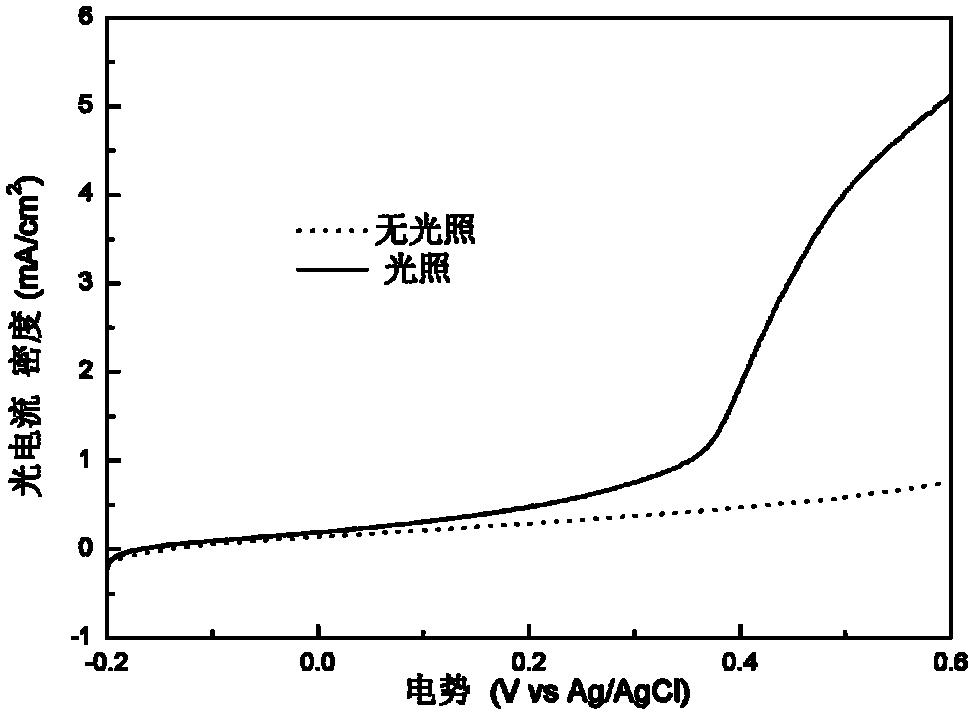

A nanorod array, transition metal technology, applied in photosensitive devices, semiconductor/solid-state device manufacturing, electrolytic capacitors, etc., can solve the problems of low photoelectric conversion efficiency of batteries, short carrier diffusion paths, and low hole movement rates. Achieve the effect of improving the utilization rate of sunlight, improving the Fermi level and the transmission rate of photogenerated electrons, and improving the photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

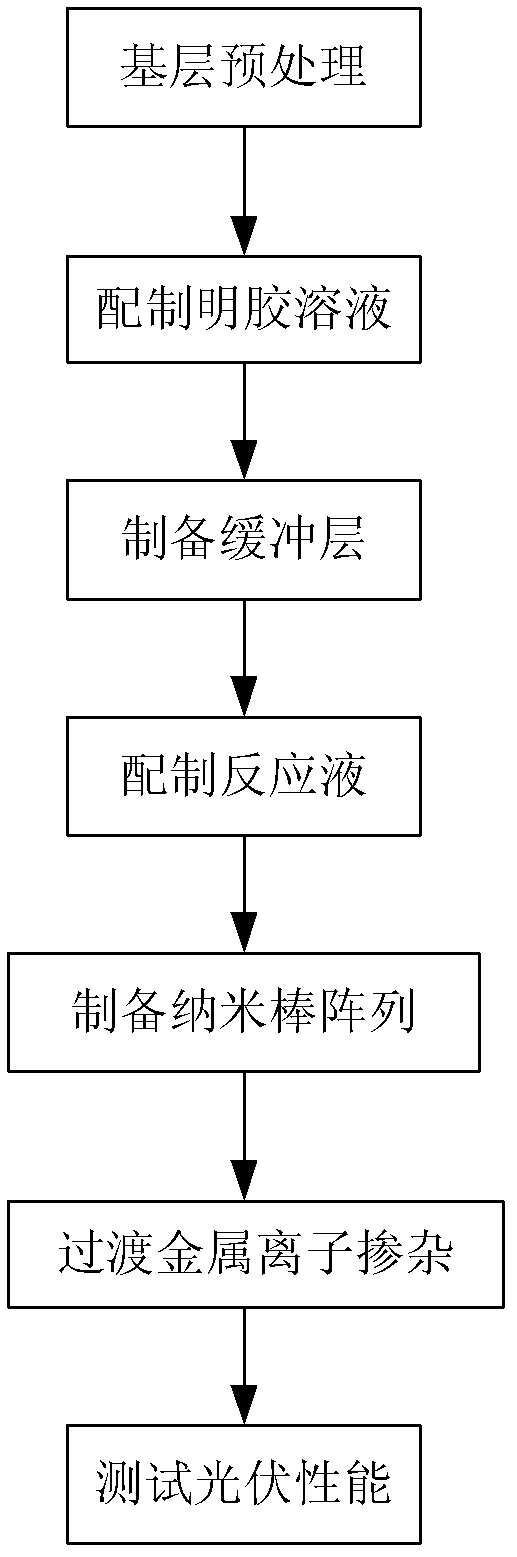

[0025] Example 1: FTO-based α-Fe 2 O 3 Preparation of nanorod photoanode

[0026] (1) Prepare FTO conductive glass substrate: cut FTO into strips, and ultrasonically clean each with acetone, absolute ethanol and deionized water for 10 to 30 minutes, each with ultrasonic power of 200 watts;

[0027] (2) From 0.540~1.622g FeCl 3 .6H 2 O, 5wt% polyvinyl alcohol (PVA) aqueous solution and 0.3wt% HCl (36.5%~38%) solution to prepare 20mL gelatin solution;

[0028] (3) Obtain a yellow-green FeOOH prefabricated film on the FTO conductive glass through the glue spinning technology;

[0029] (4) After sintering at 300~500℃ for 1~5 hours, reddish brown α-Fe is obtained 2 O 3 The buffer layer;

[0030] (5) Prepare reaction solution: 0.540~1.622g FeCl 3 .6H 2 O and 1.70~2.55g NaNO 3 Dissolved in 20mL of HCl solution and ethanol with a volume ratio of 3:3~7;

[0031] (6) Put the FTO with the buffer layer obtained in step (4) into a polytetrafluoroethylene lined autoclave, and transfer the reaction sol...

Embodiment 2

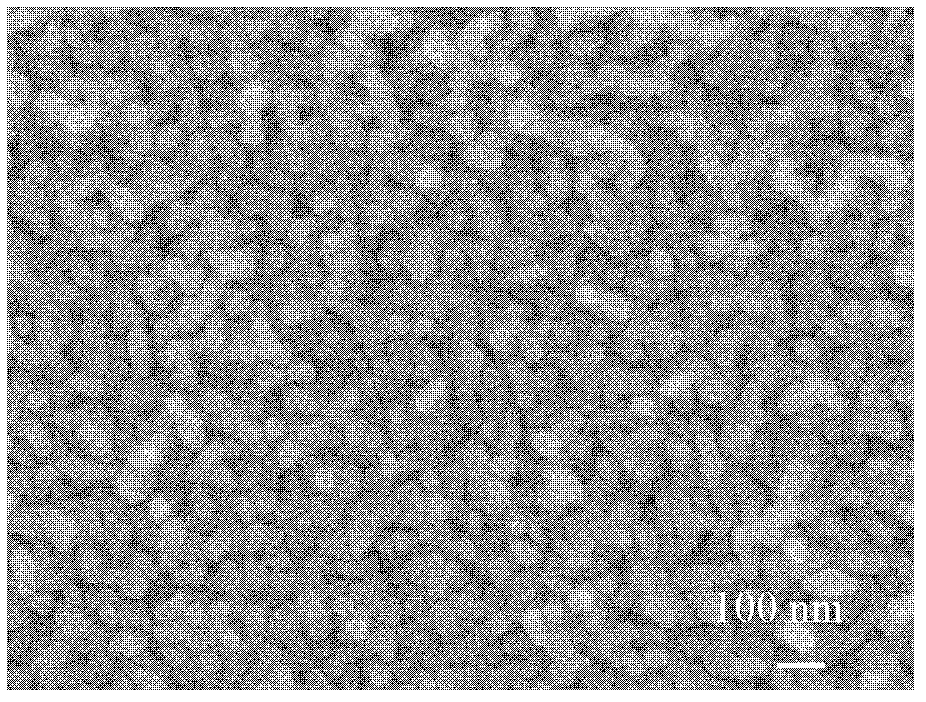

[0034] Example 2: α-Fe 2 O 3 Nanorod photoanode undergoes transition metal Sn through liquid phase chemical reaction 4+ Doping

[0035] (1) 0.01~0.5g SnCl 4 ·5H 2 Dissolve O in 10 mL of ethanol, and prepare 20-30 mL of 1~2mg / mL ethanol solution doped with transition metal ions;

[0036] (2) The step (8) obtained in Example 1 has α-Fe 2 O 3 The substrate of the nanorod array is placed in a polytetrafluoroethylene lined autoclave, and the transition metal ion ethanol solution in step (1) is transferred into it and the autoclave cover is tightened;

[0037] (3) Put the autoclave in step (2) into an electric heating constant temperature blast drying oven at 70-120°C for 4-6 hours;

[0038] (4) The product obtained in step (3) is washed sequentially with deionized water and absolute ethanol, and dried in an oven at 40-80°C for 6-12 hours to obtain α-Fe doped with transition metal ions 2 O 3 Nanorod array.

[0039] The transition metal ion Ti of this embodiment 4+ , Sn 2+ , Mn 2+ , Cu 2+ , Cu...

Embodiment 3

[0040] Example 3: α-Fe with metal Ti as the base 2 O 3 Preparation method of nanorod photoanode

[0041] (1) Preparing the base Ti foil: cutting FTO into strips, polishing, and ultrasonic cleaning with acetone, absolute ethanol and deionized water for 10-30 minutes each, the ultrasonic power is 200 watts;

[0042] (2) From 0.540~1.622g FeCl 3 .6H 2 O, 5wt% polyvinyl alcohol (PVA) aqueous solution and 0.3wt% HCl (36.5%~38%) solution to prepare 20mL gelatin solution;

[0043] (3) Using printing technology repeatedly to obtain FeOOH prefabricated film on Ti foil;

[0044] (4) Sintering at 300~500℃ for 1~5 hours to obtain α-Fe 2 O 3 The buffer layer;

[0045] (5) Prepare reaction solution: 0.540~1.622g FeCl 3 .6H 2 O and 1.70~2.55g NaNO 3 Dissolved in 20mL of HCl solution and ethanol with a volume ratio of 3:3~7;

[0046] (6) Put the Ti foil with buffer layer obtained in step (4) into a polytetrafluoroethylene lined autoclave, and transfer the reaction solution in step (5) into it;

[0047] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com