Steel for high-ductility anti-seismic structure with yield ratio smaller than or equal to 0.70 and production method of steel

A seismic-resistant structure and high-toughness technology, applied in the field of building structural engineering steel and its manufacturing, can solve the problems of high content of precious alloying elements Ni and Mo, complex heat treatment process of steel plate, low tensile strength level, etc., and achieve a large safety factor. , the effect of easy mass production, low welding crack susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below:

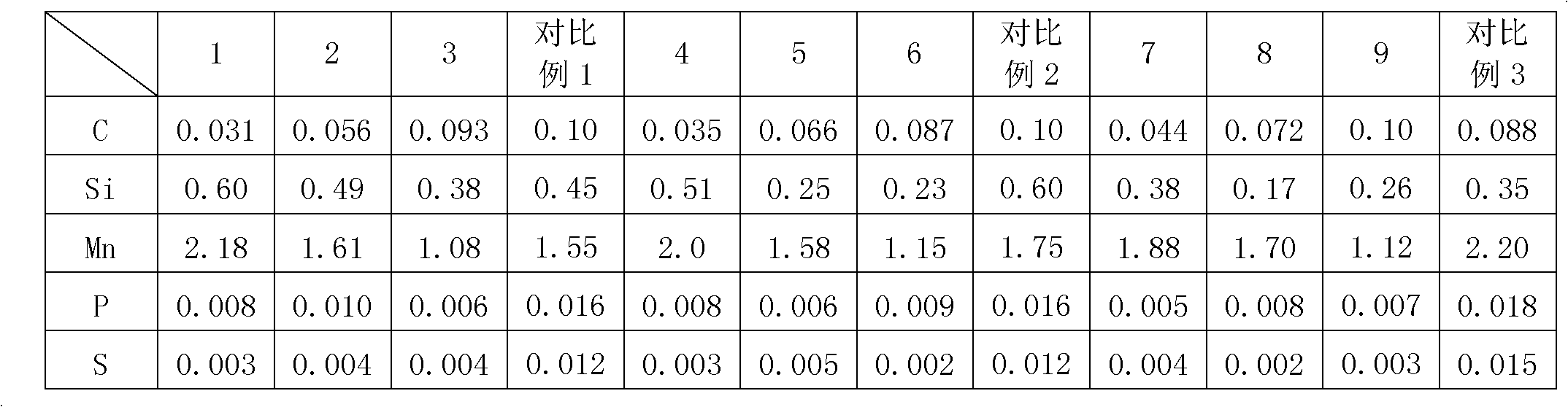

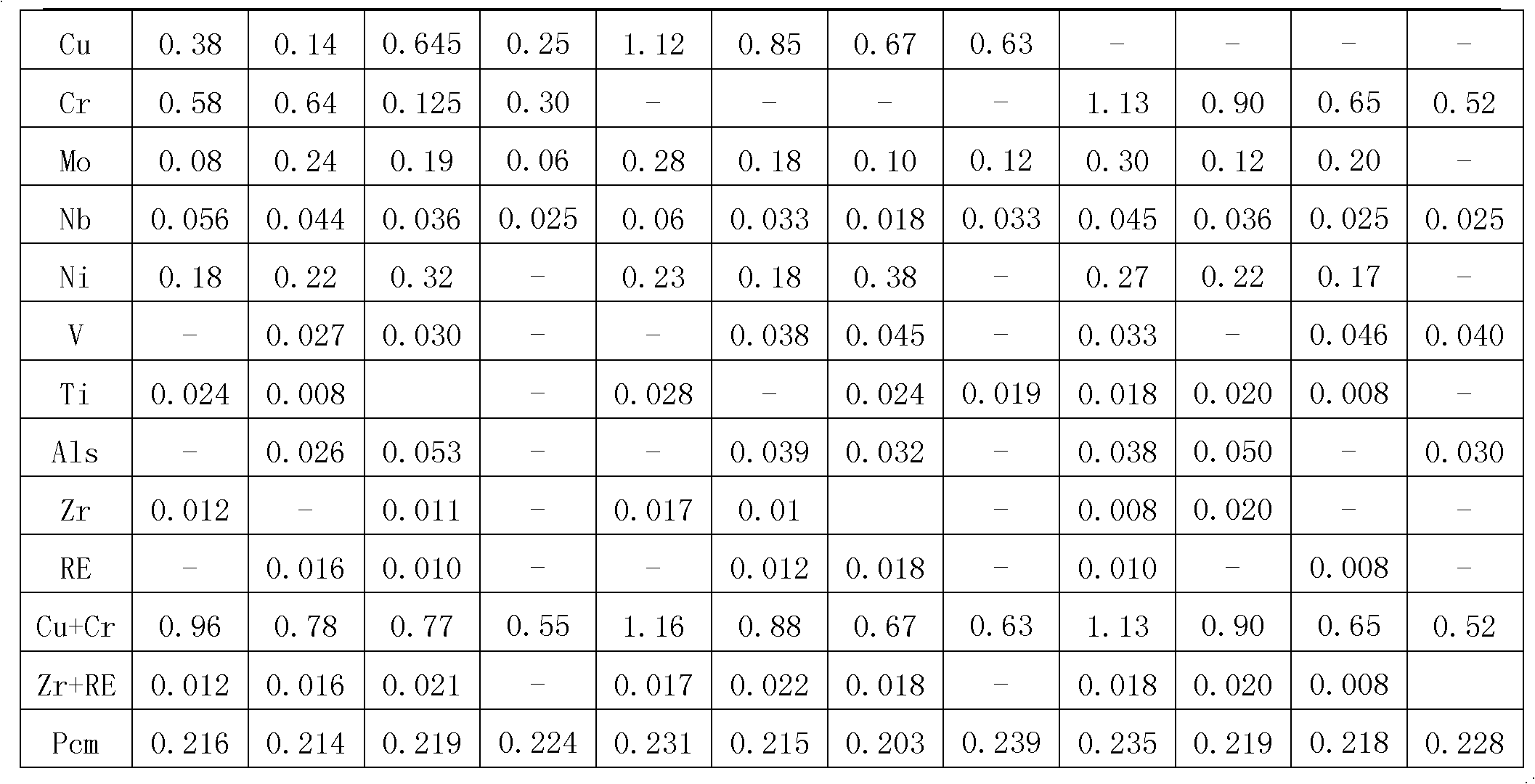

[0039] The test conditions of each embodiment: the chemical composition and weight percentage content of each implementation and comparative examples are shown in Table 1;

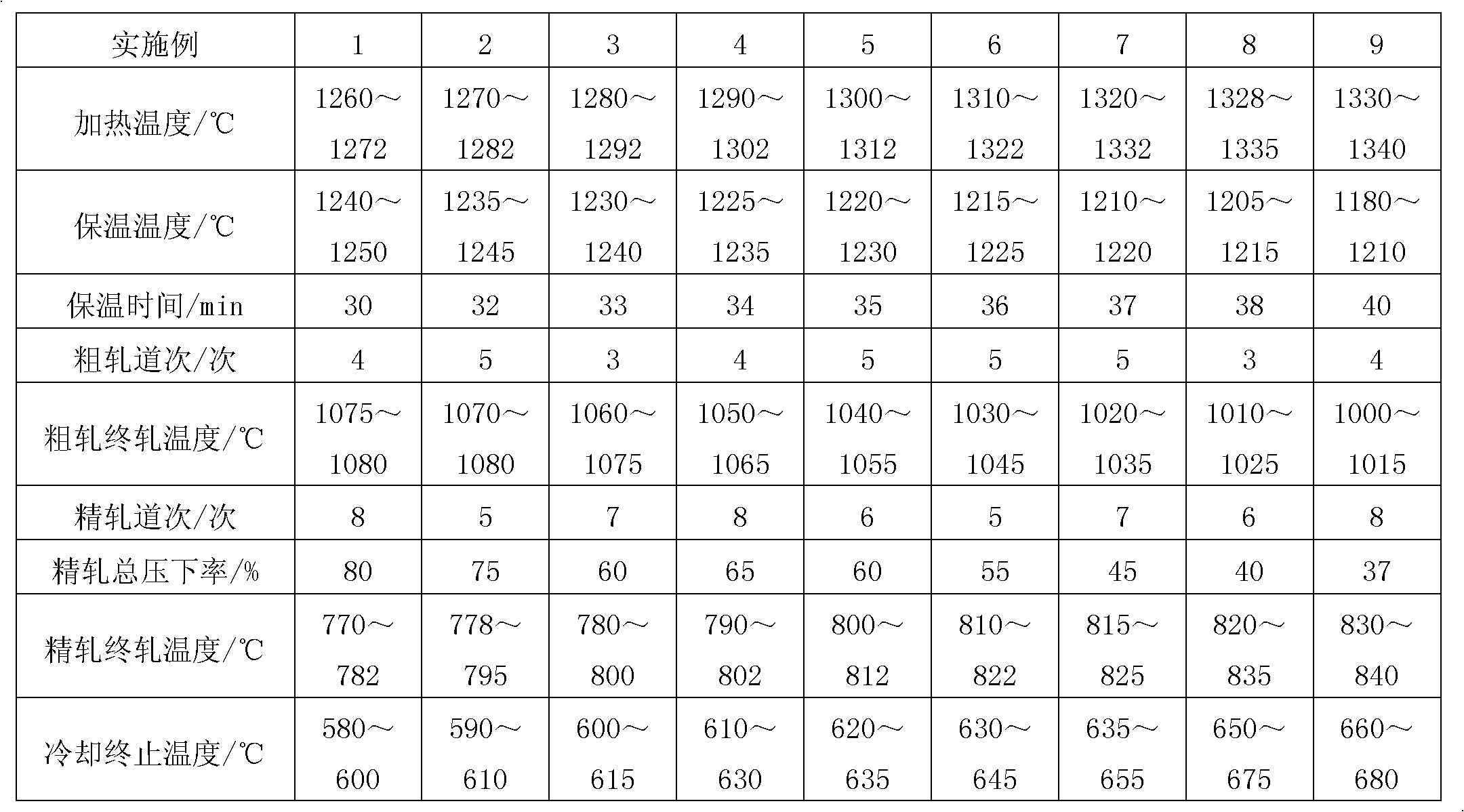

[0040] The main process parameters of each implementation and comparative examples are shown in Table 2, and are produced according to the following steps:

[0041] 1) Smelting and refining outside the furnace;

[0042] 2) Using full continuous casting to protect and pour into billets;

[0043] 3) Heating the billet, controlling the heating temperature at 1260-1340°C, controlling the heating rate at 7-10min / cm, and keeping it at 1180-1250°C for at least 30min;

[0044] 4) Rough rolling: the controlled rolling pass is 3-5 passes, and the final rolling temperature is controlled to be 1000-1080°C;

[0045] 5) Finish rolling: control the rolling pass to 5-8 passes, the total reduction rate is 37-80%, and the final rolling temperature is 770-840°C;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com