Antenna housing substrate and preparation method thereof

A cover substrate and radome technology, applied in the field of radome, can solve the problems of substrate dielectric constant, large dielectric loss, glass fiber dielectric constant and large dielectric loss, unsuitable for radome, etc., to achieve dielectric loss Small, low dielectric constant, promoting the effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

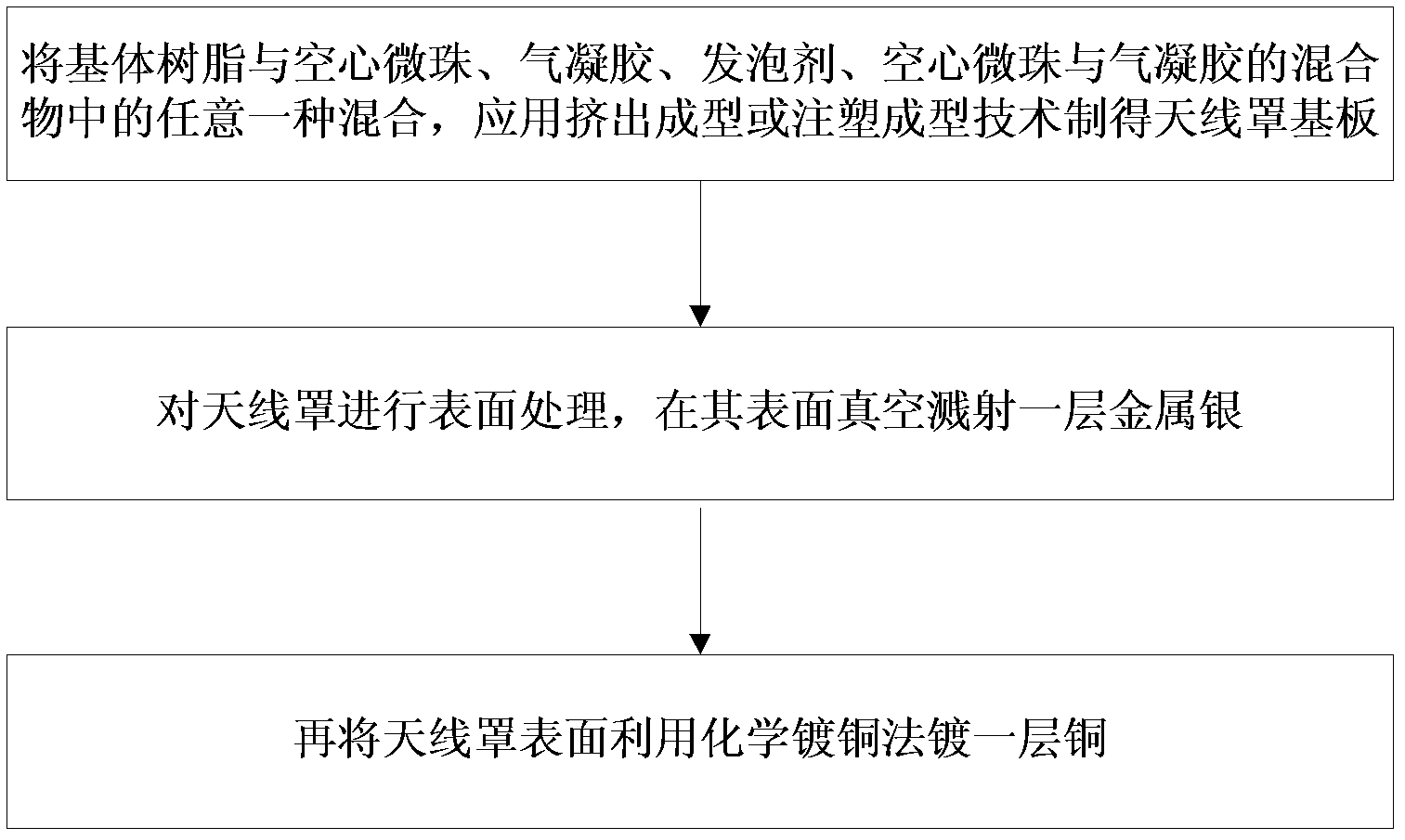

[0019] Mix high-density polyethylene with a mass ratio of 85% and silica hollow microspheres with a mass ratio of 15%, use injection molding technology to process the radome substrate, perform surface treatment on the radome, and vacuum sputter a layer on its surface metal copper, such as figure 1 Embodiment 1 The radome substrate preparation method flow chart is shown.

[0020] It should be understood that in this embodiment, adding hollow silica beads to the formulation can reduce the density of the radome substrate, reduce the dielectric loss of the plate, and lower its dielectric constant.

[0021] It should be understood that in this embodiment, parameters such as the thickness of the radome substrate and the density of the radome substrate during the injection molding process may be controlled as required.

[0022] It should be understood that in this embodiment, a layer of metal copper is vacuum sputtered on the surface of the radome substrate in order to continue etch...

Embodiment 2

[0025] Mix polypropylene with a mass ratio of 75% and silica airgel with a mass ratio of 25%, process it into a radome substrate by extrusion molding process, carry out surface treatment on the radome substrate, and vacuum sputter on its surface A layer of metallic silver, and then a layer of copper film is plated on the silver-plated radome substrate by electroless copper plating.

[0026] It should be understood that copper-plating the radome substrate after vacuum sputtering metallic silver is to increase the thickness of the radome substrate to meet specific requirements.

[0027] It should be understood that electroless copper plating is an inherently catalytic redox reaction. First, treat the insulating substrate with an activator, so that a layer of active particles is adsorbed on the surface of the insulating substrate. Usually, metal palladium particles are used. Copper ions are reduced on these active metal palladium particles, and these reduced metal copper crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com