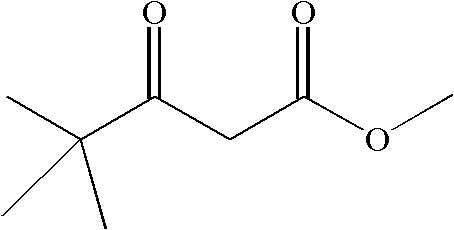

Preparation method of 4,4-dimethyl-3-keto-methyl valerate

A technology of methyl valerate and dimethyl valerate, applied in the field of organic synthesis, which can solve the problems of high risk, high price, and high content of sodium hydride, and achieve the effects of less raw material consumption, mild reaction, and reduced risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

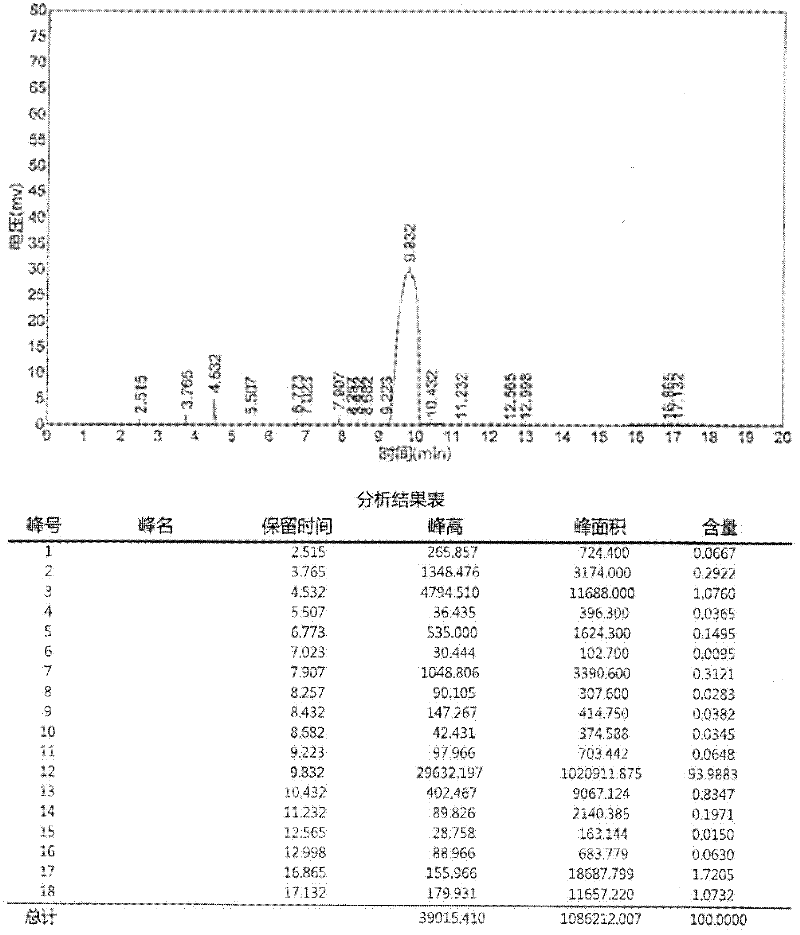

[0023] First add dehydrated toluene (1mol pinacolone, dosage 400-410mL) to the kettle, and add anhydrous pinacolone dropwise at a reaction temperature of 55-60°C under different ratios of reaction raw materials, and the dropping time is controlled at 1.5~2h, keep warm at 55~60°C for 3h, then dropwise add water (1mol pinacolone, dosage 100~110mL), cool down to below 30°C, then add dropwise 18Wt.% hydrochloric acid aqueous solution, adjust pH=4~5, Stand still for 1h, remove the aqueous solution layer by layer, wash the upper organic solution layer with water, 10Wt.% sodium bicarbonate aqueous solution, and water until neutral, evaporate toluene and then distill under reduced pressure. 10 3 Pa fraction to obtain the product. The experimental data are shown in Table 1:

[0024] Table 1: Effect of Raw Material Ratio on Product Content and Yield

[0025]

[0026]

[0027] 1) Embodiment 2, 3, 4 and 5 find out: when pinacolone and dimethyl carbonate charge ratio are constant,...

Embodiment 9-13

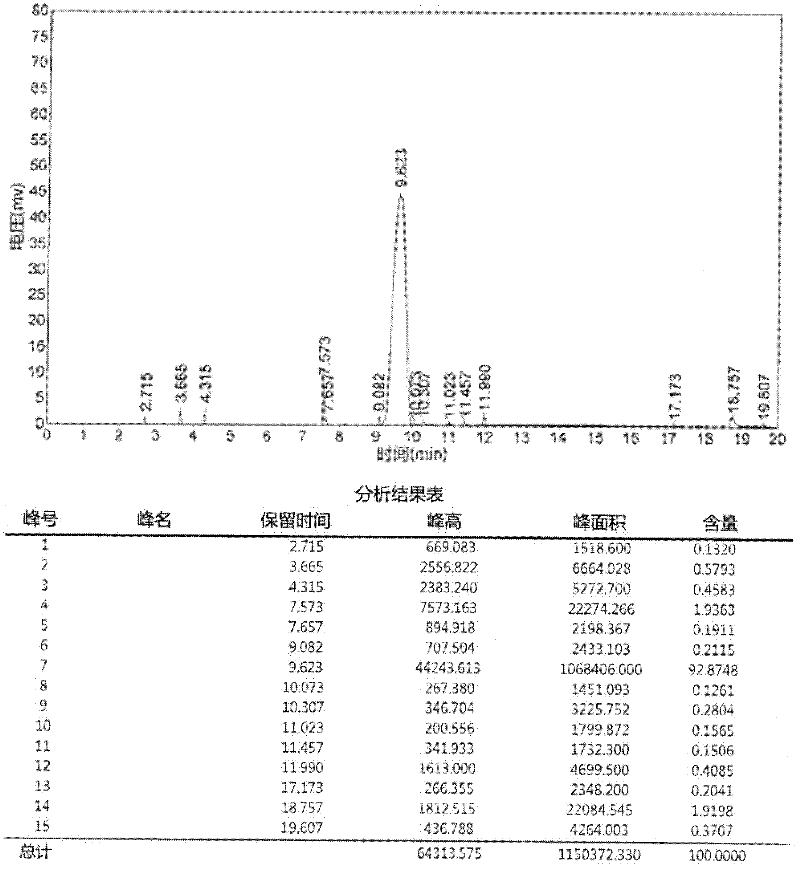

[0030] Under the same condition of raw material ratio, pinacolone: sodium hydride: dimethyl carbonate is in 1: 2: 2, and the toluene consumption is by 400mL / 1mol pinacolone, reacts and prepares under different temperature, different dropping time, different holding time 4,4-Dimethyl-3-keto-pentanoic acid methyl ester. After the reaction, add water dropwise (1mol pinacolone, dosage 100-110mL), lower the temperature to below 30°C, then add dropwise 18Wt.% hydrochloric acid aqueous solution to adjust the pH=4-5, let it stand for 1h, remove the aqueous solution layer by layer, and the upper layer organic The solution layer was washed with water, 10Wt.% sodium bicarbonate aqueous solution, and water until neutral, evaporated toluene and then distilled under reduced pressure. The collection temperature was 93-95°C and the pressure was 2.7×10 3 Pa fraction to obtain the product. The experimental data is shown in the following table: The experimental data is shown in Table 2:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com