Preparation method of 2-methyl-3-biphenylmethanol

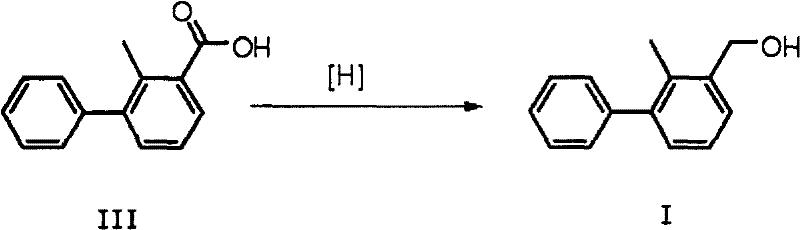

A technology of phenyl benzyl alcohol and methyl benzoic acid is applied in the field of preparation of 2-methyl-3-phenyl benzyl alcohol, can solve the problems of harsh reaction conditions, low yield, many side reactions, etc., and achieves the reaction yield. The effect of high rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

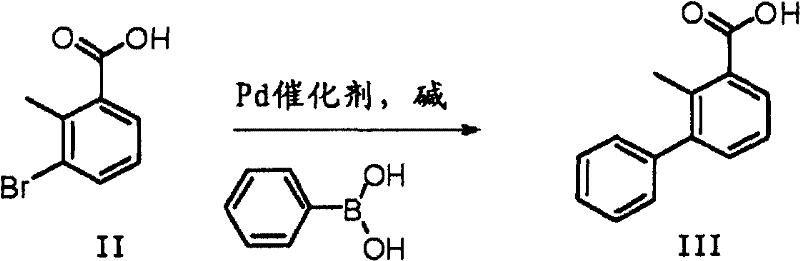

[0030] Add 3-bromo-2-methylbenzoic acid (4.9g, 22.4mmol), palladium acetate (55mg, 0.23mmol), sodium carbonate (7.2g, 68.1mmol) to the 500mL reaction flask under nitrogen protection (reaction system pH 8-9), phenylboronic acid (3.1 g, 25 mmol) and water (125 mL). The reaction mixture was stirred at room temperature for 1 hour. The reaction mixture was poured into 2N hydrochloric acid, the product was extracted with ethyl acetate (3×150 mL), the organic layers were combined, dried and concentrated to give the title compound (90% yield).

Embodiment 2

[0032] Add 3-bromo-2-methylbenzoic acid (4.9g, 22.4mmol), 5% palladium / carbon (1.12mmol), potassium carbonate (6.2g, 44.8mmol) to the 500mL reaction flask under nitrogen protection (reaction system pH 8-9), phenylboronic acid (3.1 g, 25 mmol) and a mixture of N,N-dimethylacetamide and water (20 / 1 (v / v), 125 mL). The reaction mixture was stirred at 80 °C for 1 hour. The reaction mixture was poured into 2N hydrochloric acid, the product was extracted with ethyl acetate (3×150 mL), the organic layers were combined, dried and concentrated to give the title compound (94% yield).

Embodiment 3

[0034] Add 3-bromo-2-methylbenzoic acid (4.9g, 22.4mmol), palladium / carbon (1.12mmol), sodium carbonate (4.75g, 44.8mmol) in 500mL reaction flask (reaction system pH value is 8-9 ), sodium tetraphenylborate (2.0 g, 6.05 mmol) and water (125 mL). The reaction mixture was stirred and refluxed for 3 hours. The reaction mixture was poured into 2N hydrochloric acid, the product was extracted with ethyl acetate (3×150 mL), the organic layers were combined, dried and concentrated to give the title compound (92% yield).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com