Biochemical treatment technology for viscose waste water with physico-chemical method and CASS (Cyclic Activated Sludge System) method

A viscose fiber, biochemical treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of reducing the consumption of raw materials and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

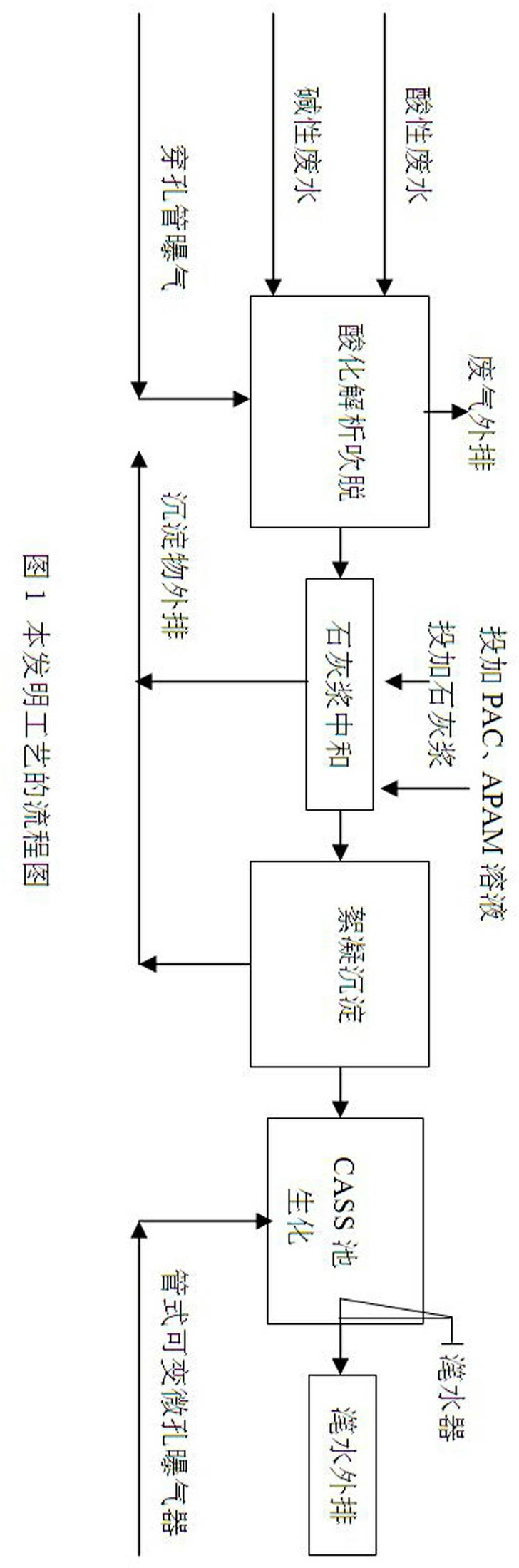

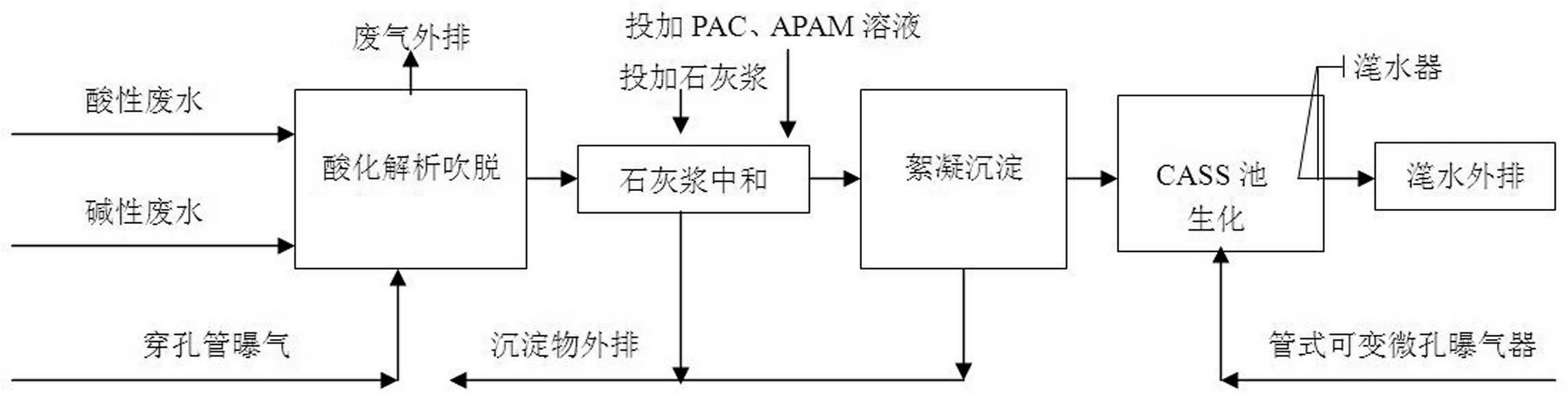

Method used

Image

Examples

Embodiment 1

[0030]

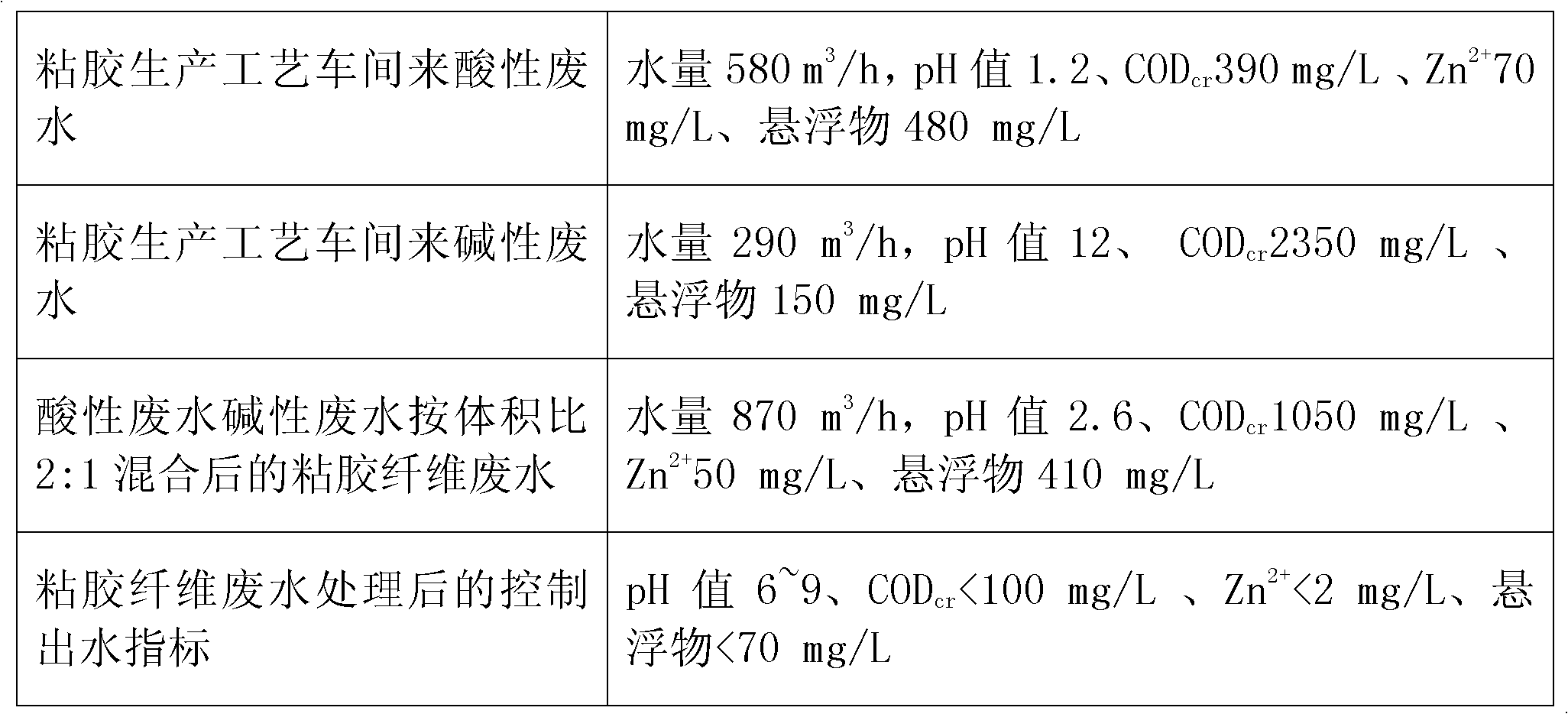

[0031] The viscose production process workshop mainly discharges acidic wastewater and alkaline wastewater. Under normal production process conditions, the volume of acidic wastewater is twice that of alkaline wastewater. Acidic wastewater mainly contains H 2 SO 4 , ZnSO 4 and Na 2 SO 4 , using the following acid wastewater measurements: pH 1.2, COD cr 390mg / L, Zn 2+ 70mg / L, suspended matter 480mg / L. Alkaline wastewater mainly contains NaOH, Na 2 S, CS 2 and cellulose xanthate, using the following measurements for alkaline wastewater: pH 12, COD cr 2350mg / L, suspended matter 150mg / L. After acidic wastewater and alkaline wastewater are mixed at a volume ratio of 2:1, the following measured values are used: pH value 2.6, COD cr 1050mg / L, Zn 2+ 50mg / L, suspended matter 410mg / L. According to the corresponding first-level discharge standard in GB8978-96, control the effluent indicators after treatment: pH value 6-9, COD cr 2+ <2mg / L, suspended matter <70m...

Embodiment 2

[0033]

[0034] When the pH value is 2.7, after 1.5 hours of hydraulic retention acidification, the cellulose sulfonate in the wastewater will be decomposed into gaseous substances and other organic substances that are easily degraded by the CASS method. off, CS in wastewater 2 、H 2 A large amount of S will be precipitated on the water surface, which can reduce the COD in the water cr, chromaticity, and at the same time fully mixed acidic wastewater and alkaline wastewater. Add lime slurry to neutralize the lime slurry. After 0.5 hours of hydraulic retention, the pH value of the final effluent is 9.5, reaching Zn 2+ Form Zn(OH) 2 Theoretical conditions for precipitation (main). By adding 800L / h of 10% flocculant solution and 200L / h of 0.5% coagulant aid solution to the lime slurry and the terminal effluent, through hydraulic self-mixing, the suspended solids in the wastewater are accelerated to form flocs and precipitate, and the flocculation and precipitation process 4...

Embodiment 3

[0036]

[0037] When the pH value is 2.1, after 2 hours of hydraulic retention acidification, the cellulose sulfonate in the wastewater will be decomposed into gaseous substances and other organic substances that are easily degraded by the CASS method. off, CS in wastewater 2 、H 2 A large amount of S will be precipitated on the water surface, which can reduce the COD in the water cr , chromaticity, and at the same time fully mixed acidic wastewater and alkaline wastewater. Add lime slurry to neutralize the lime slurry. After 1 hour of hydraulic retention, the pH value of the final effluent is 9.8, reaching Zn 2+ Form Zn(OH) 2 Theoretical conditions for precipitation (main). By adding 600L / h of 12.5% flocculant solution and 150L / h of 1% coagulant aid solution to the lime slurry and the terminal effluent, through hydraulic self-mixing, the suspended solids in the wastewater are accelerated to form floc precipitation, and the flocculation precipitation process is 4.5 Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com