Method and device for off-line identification of parameters of three-phase asynchronous motor

An identification method and a three-phase asynchronous technology, which is applied in the control of electromechanical transmission devices, control of generators, motor generator control, etc., can solve the problems that cannot meet the conditions of no-load experiments, the direct application of frequency conversion speed regulation systems, and loads that cannot be unloaded, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

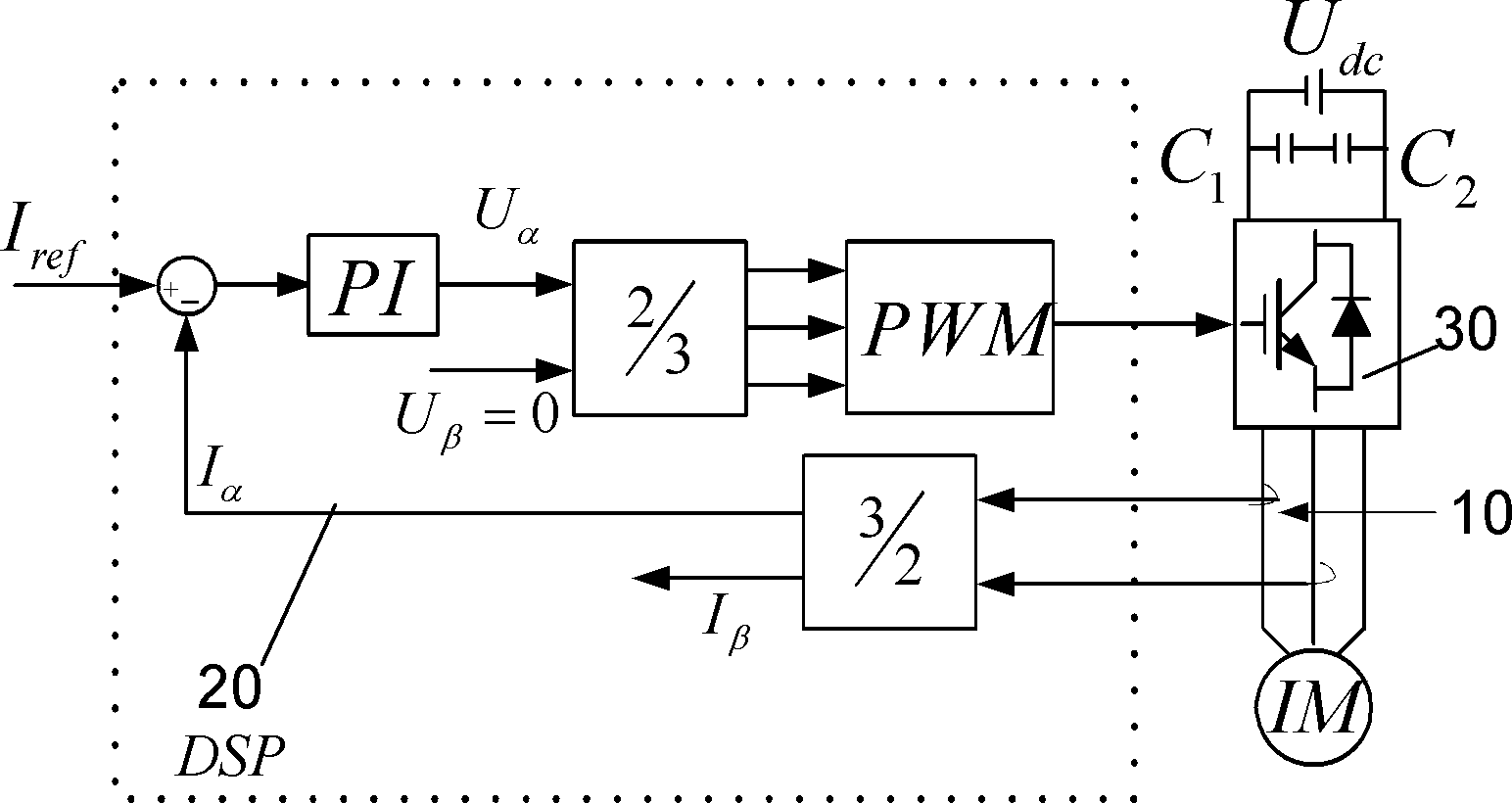

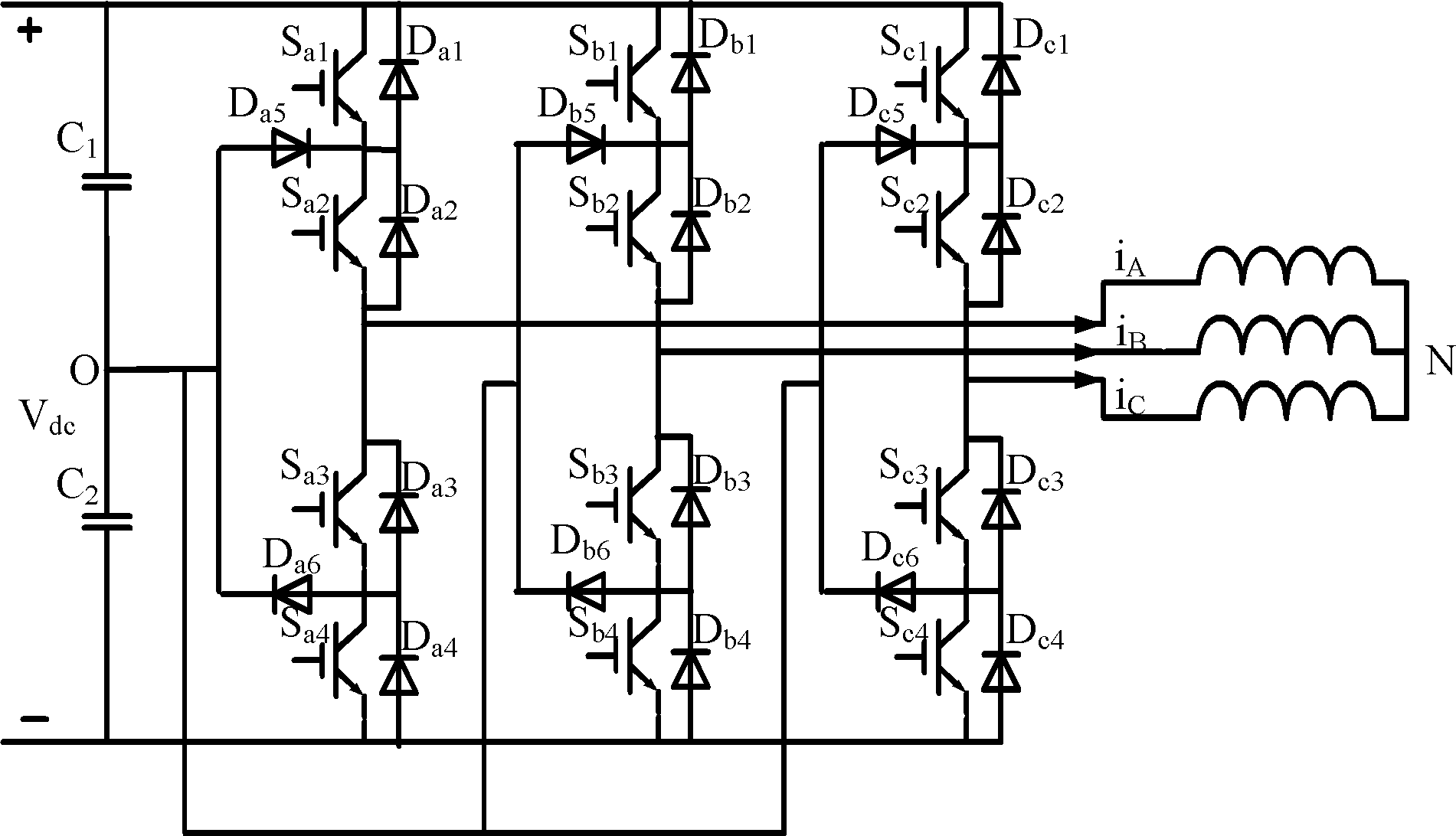

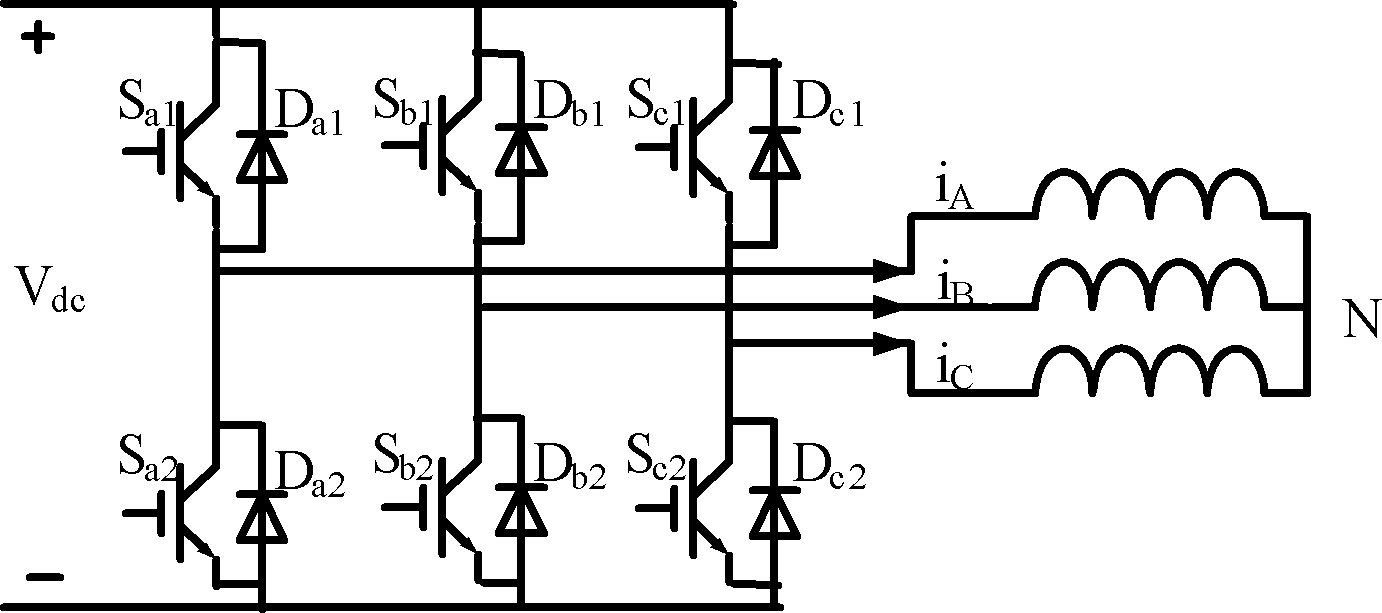

[0041]The invention can effectively realize the off-line identification of motor parameters for three-phase asynchronous motor speed regulation systems controlled by three-level and two-level inverters. The following takes the three-phase asynchronous motor speed control system controlled by a three-level inverter as an example to introduce the method of off-line identification of motor parameters.

[0042] refer to figure 1 with Figure 2a , the parameter off-line identification device of the three-phase asynchronous motor of the present invention includes a sensor 10 for detecting the terminal current output to the motor, and the sensor is a Hall sensor; and

[0043] The controller 20 performs PI adjustment according to the feedback current provided by the sensor and the given reference current, and performs Fourier analysis on the current and voltage according to the preset mathematical model, so as to obtain the DC current and DC voltage of the motor winding, and obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com