Method for recycling motor

A motor and magnet technology, applied in the field of motor reuse, can solve the problems of poor energy efficiency and inability to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

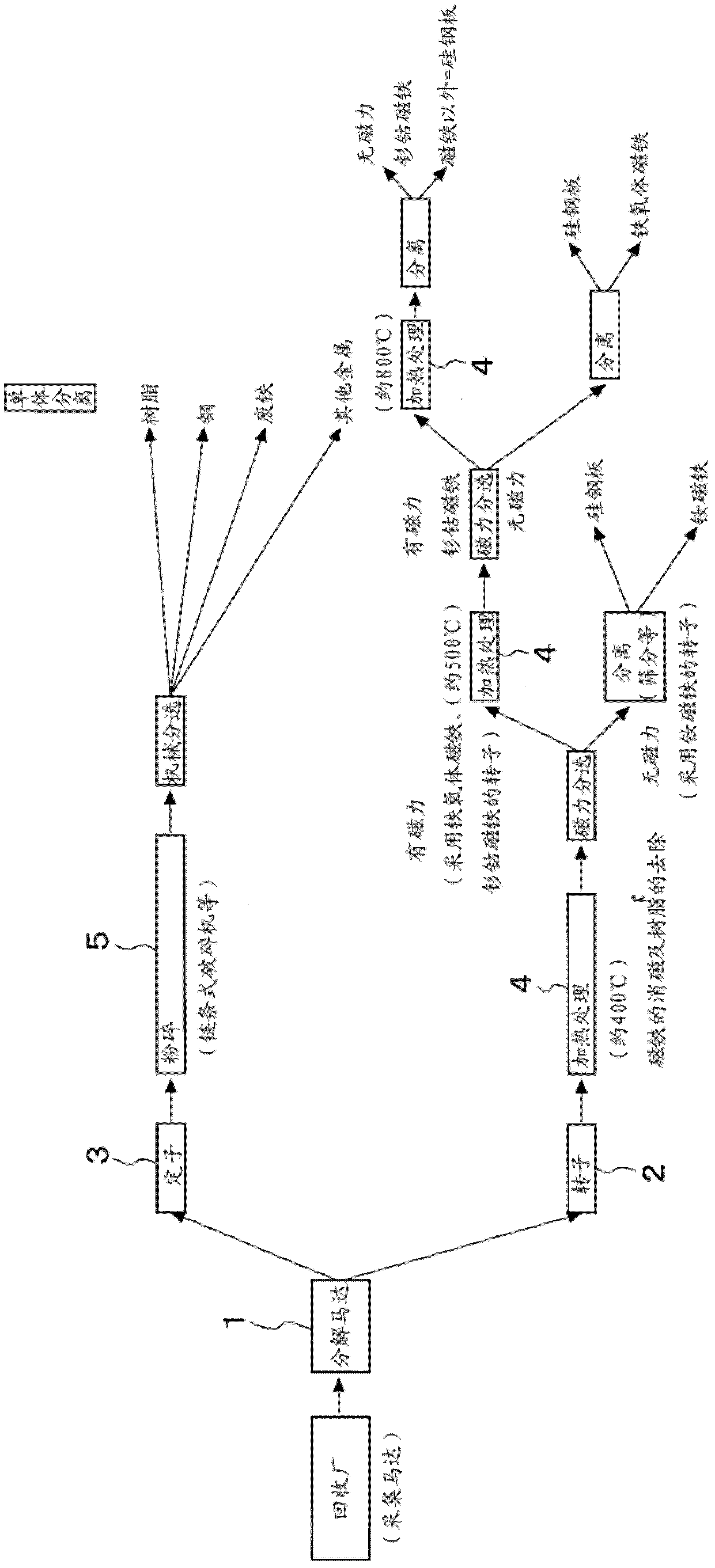

[0039] First, a recycling method of the separated rotor 2 will be described.

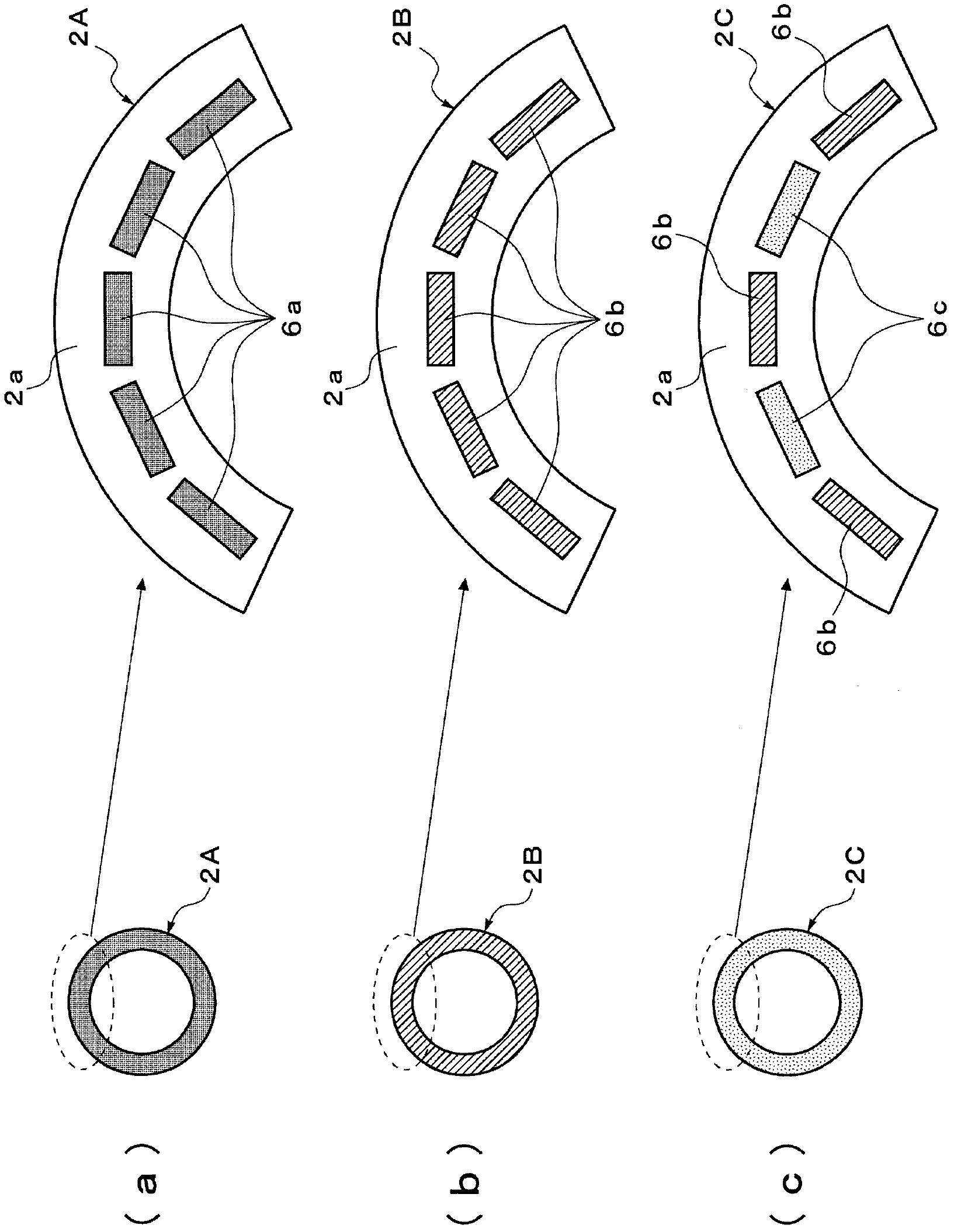

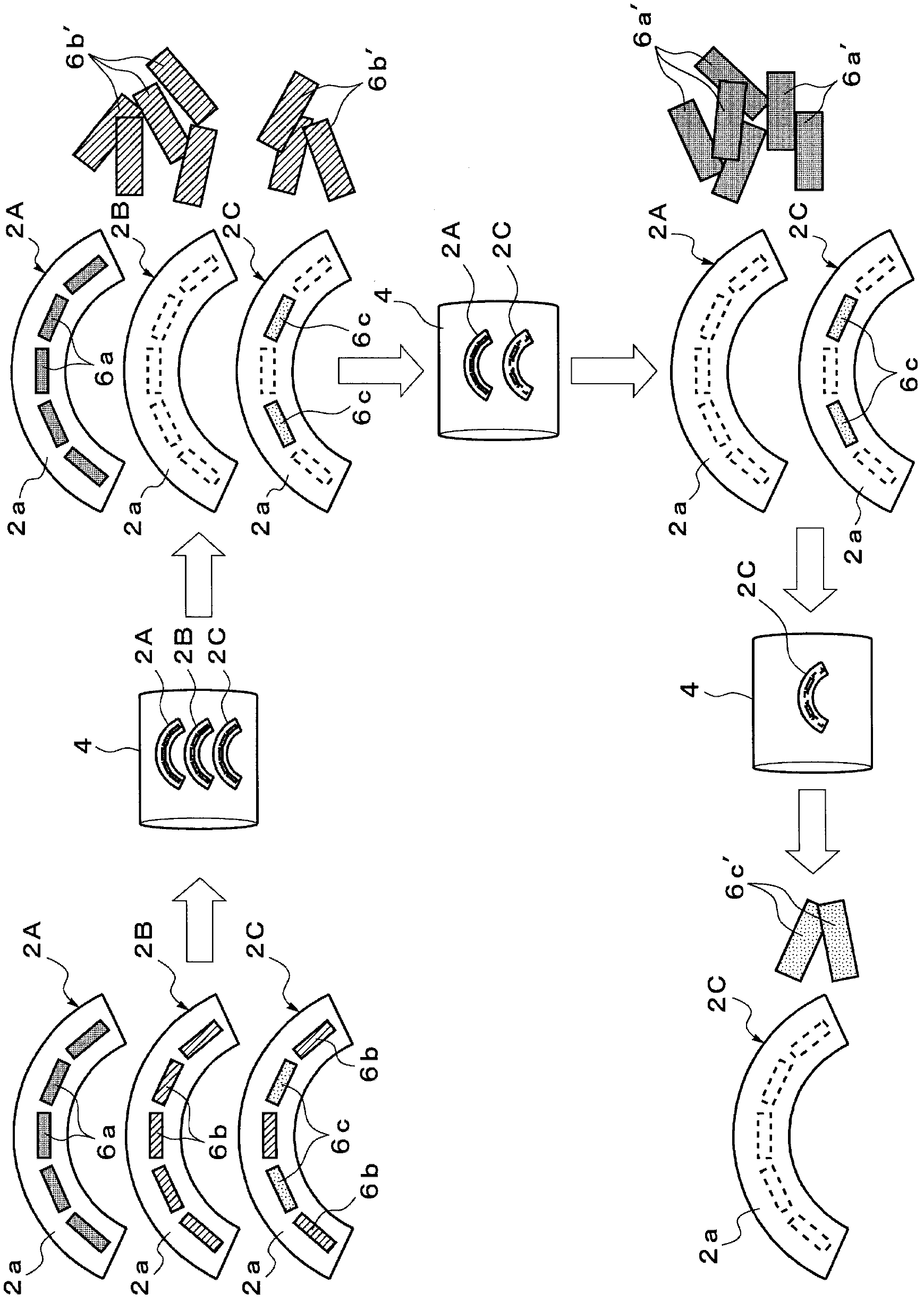

[0040] like figure 1 and image 3 As shown, three types of rotors 2 separated from the motor 1 were put into the atmospheric atmosphere furnace 4 . At this time, the three types of rotors 2 put into the atmospheric atmosphere furnace 4 are, figure 2 The ferrite magnet 6a of (a) is assembled in the rotor 2A of the rotor core 2a, figure 2 The neodymium magnet 6b of (b) is assembled in the rotor 2B of the rotor core 2a and figure 2 In (c), the neodymium magnet 6b and the samarium cobalt magnet 6c are mixed and assembled in the rotor 2C of the rotor core 2a.

[0041] Then, after the rotor 2A, the rotor 2B, and the rotor 2C were charged into the atmospheric atmosphere furnace 4, the temperature inside the atmospheric atmosphere furnace 4 was raised to 380° C. and held for 30 minutes. At this time, in the atmospheric atmosphere furnace 4, the resin covering the metal part is ashed and removed, and...

Embodiment 2

[0052] Next, a method of recycling the separated stator 3 will be described.

[0053] like figure 1 and Figure 4 As shown, a plurality of stators 3 separated from a motor 1 are put into a chain crusher 5 . At this time, the rotation shaft 5c of the chain crusher 5 is driven to rotate by the drive of the motor 5d, and the chain 5a connected to the rotation shaft 5c is rotated in the cylindrical body 5b.

[0054] And, the stator 3 put into the chain crusher 5 is knocked for about 1 minute by the chain 5a rotating in the cylinder 5b, thereby crushing the silicon steel plate or other metals such as aluminum and copper coils forming the stator core, And the resin covering the stator 3 is pulverized. Here, other metals such as aluminum refer to unmagnetized metals. In addition, since the silicon steel sheet and other metals are crushed by the impact of hitting the flexible chain 5a, the silicon steel sheet itself is hardly deformed and crushed, and does not become entangled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com