Method for preparing polyion doping type iron phosphate with metallurgy iron dust content mud serving as main raw material

A main raw material, multi-ion technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problem of high cost and achieve the effect of reducing the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

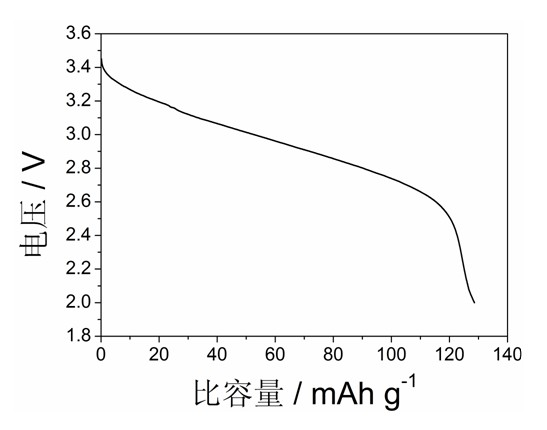

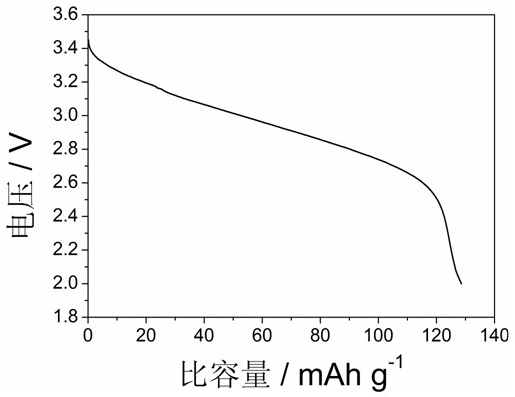

Image

Examples

Embodiment 1

[0020] Example 1: Bake the converter mud at 110°C for 5 hours and grind it to an average particle size of 1 μ m powder; inject 50 mL of accurately prepared 3 mol / L sulfuric acid solution into a 250 mL beaker, weigh 10 g of converter mud powder, slowly add to the solution and stir, add deionized water to make the reaction system 80 mL, room temperature Lower the reaction for 1 h; filter with suction and repeatedly wash the filter cake, repeat 3 times, combine the filtrates at all levels; add 30% hydrogen peroxide to the filtrate, and use potassium ferricyanide to calibrate the oxidation end point (take a small amount of solution and drop it on the ferricyanide On potassium solids, if there are ferrous ions in the solution, the drop point will be blue, otherwise it will not change color); fill the oxidized filtrate with deionized water to 300 mL, pour it into a 500 mL beaker, and place it in 70 ℃ water bath, add 7 mL of 85% phosphoric acid under stirring, and then add 25% ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com