Organic solar cell

A solar cell, organic technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low efficiency, achieve the effect of improving transmission and collection efficiency, reducing series resistance, and improving interface contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

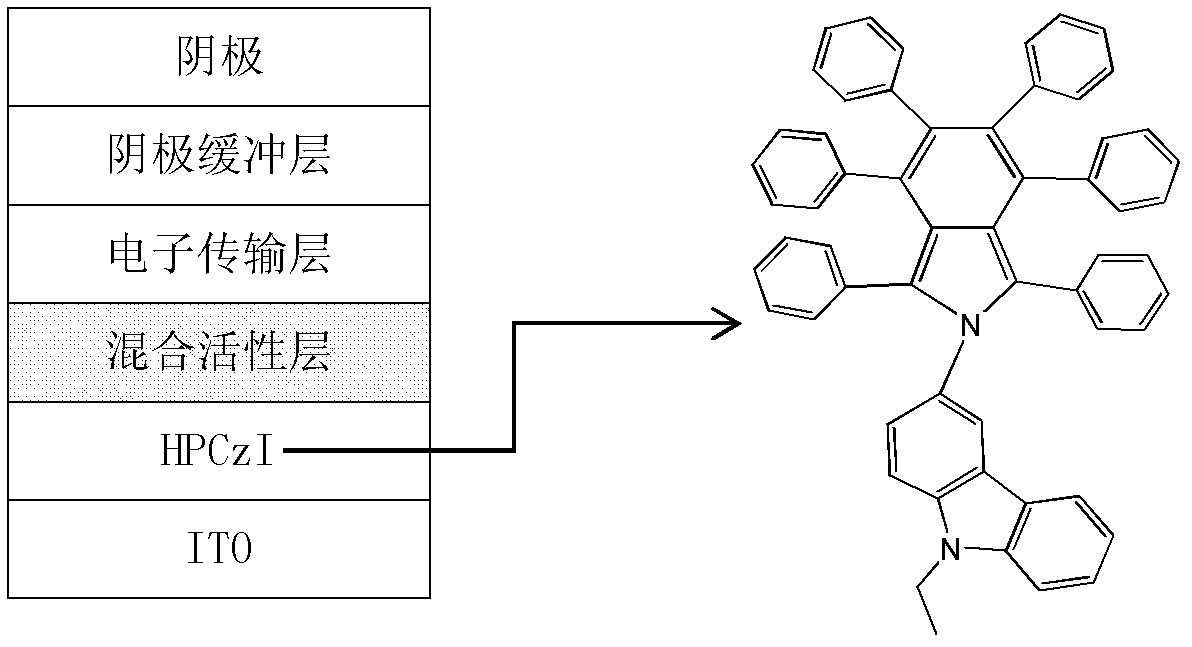

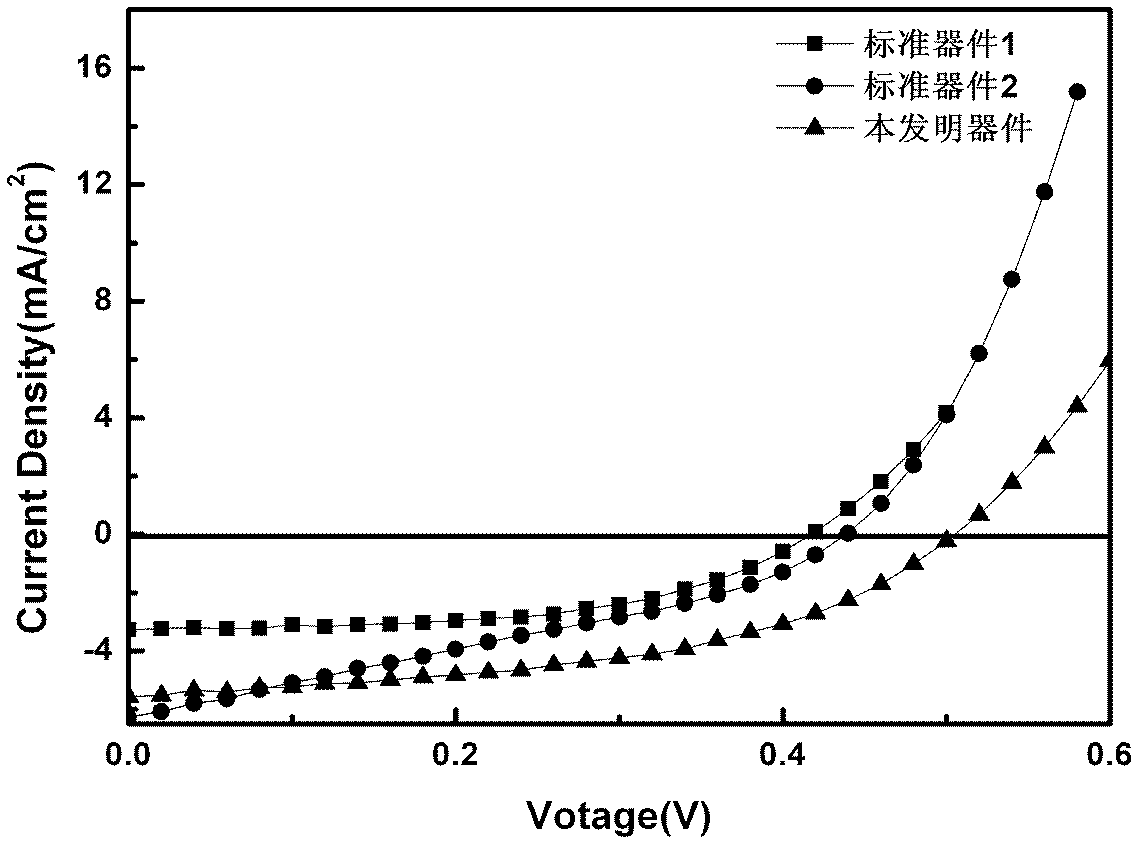

[0029] Organic solar cells were evaporated on a cleaned ITO glass substrate (sheet resistance of 15 Ω / □). The ITO glass substrate was washed with detergent, acetone, isopropanol and deionized water for 30 minutes, and then heated at 120°C. Bake for at least 10 minutes, before evaporating the organic layer, and then use O 2 Plasma treatment for 50 seconds. Organic material is at 3.5 x 10 -4 It is vacuum evaporated under the pressure of Pa, and the vacuum when evaporating cathode aluminum is 2×10 -3 Pa. The ITO substrate was at room temperature during evaporation, and HPCzI was sublimated and purified before use. The purity of C60 used in the experiment reached 99.9%. The evaporation rate of HPCzI is about 1 ? / s, the photoactive layer is CuPc and C60 co-evaporation, the evaporation rate is 0.25 ? / s at the mixed concentration of 1:1, and the evaporation rate of electron transport layer C60 is about 0.45 ? / s, the evaporation rate of TPBi is 0.55 ? / s, and the evaporation rat...

Embodiment 2

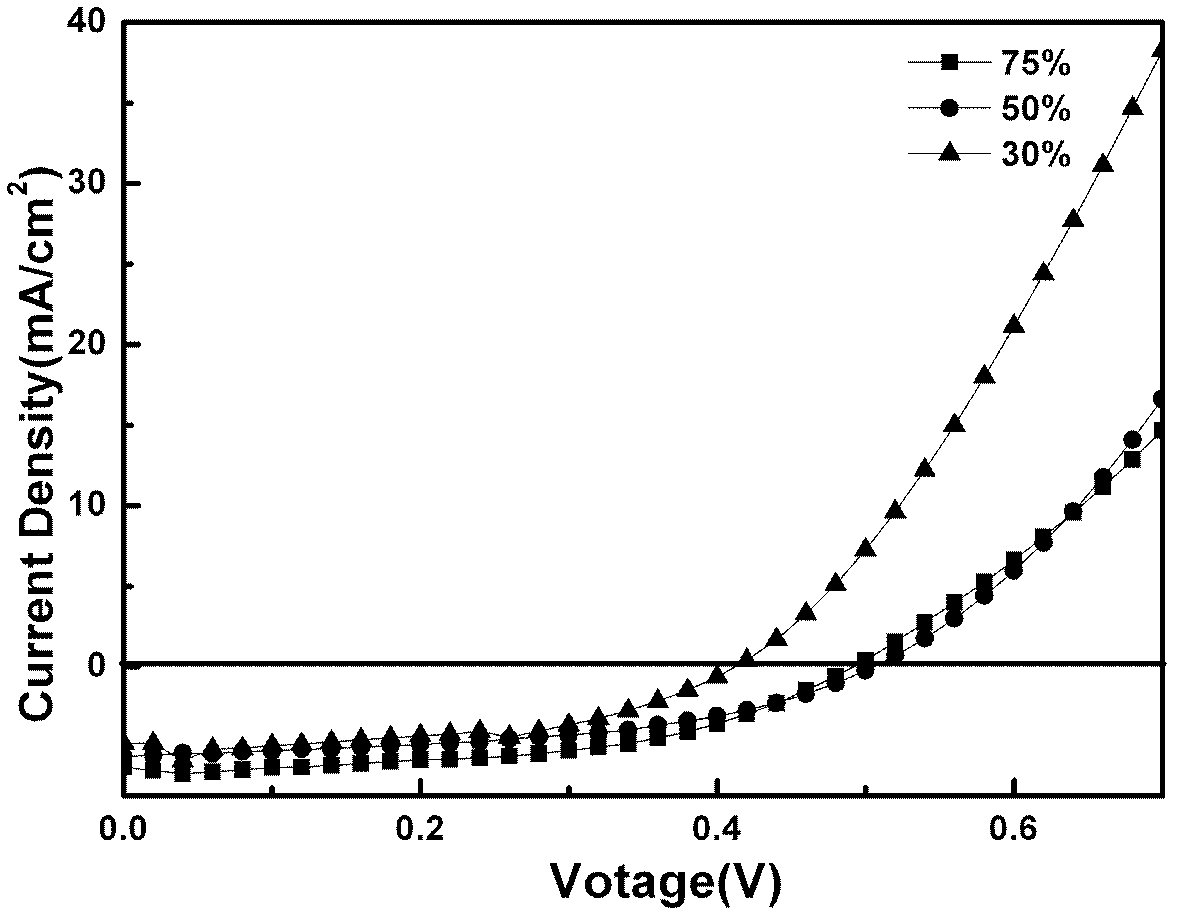

[0038] This example shows the short-circuit current, open-circuit voltage, fill factor and power efficiency of the device when HPCzI and CuPc materials are used as the anode buffer layer respectively, and the CuPc concentration in the mixed photoactive layer is 30%, 50%, and 75%.

[0039] Standard device structure: glass substrate / ITO / CuPc (150 ?) / CuPc: C60 (250 ?) / C60 (200 ?) / TPBi (80 ?) / Al (1000 ?).

[0040] The device structure of the present invention: glass substrate / ITO / HPCzI (150?) / CuPc: C60 (250?) / C60 (200?) / TPBi (80?) / Al (1000?).

[0041] Table 2 shows the corresponding values of short-circuit current, open-circuit voltage, power efficiency and fill factor of devices of the present invention and standard devices with different CuPc doping concentrations. It can be seen from Table 2 that the device efficiency of the device of the present invention is higher than that of the standard device when the CuPc concentration is 30%, 50%, and 75%.

[0042] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com