Cooling silane intermediate storage tank with outer coiled pipe

An intermediate storage tank and outer coil technology, which is applied in the fields of electronics and photovoltaics, can solve the problems of high production costs, long process lines, and high failure probability of Dewar flasks, and achieves simple structure, high safety, and reduced leakage accident probability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

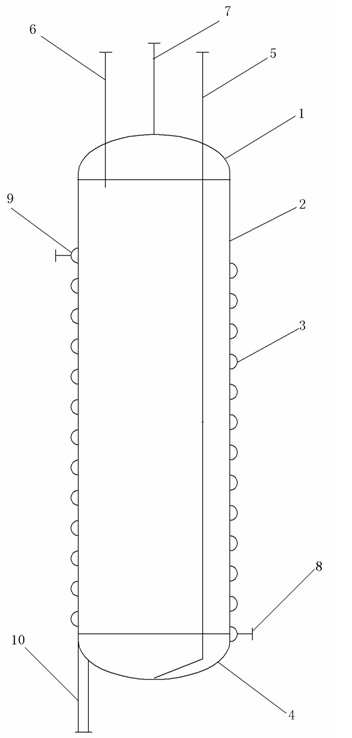

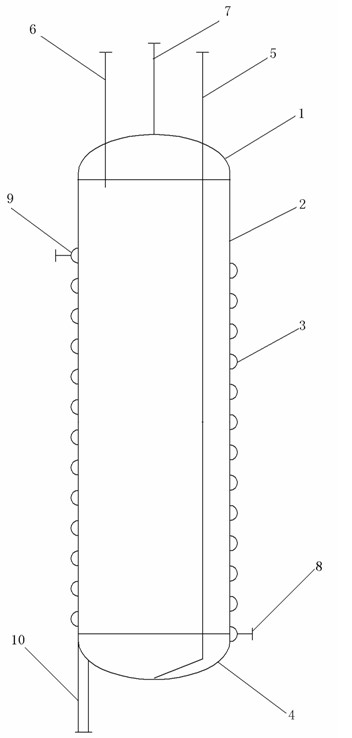

[0014] Such as figure 1 Shown: an external coil cooling silane intermediate storage tank, including an upper head 1, a cylinder body 2, a coil 3, a lower head 4, a feed pipe 5, a discharge pipe 6, a temperature measuring pipe 7, a refrigerant and The heat medium inlet 8, the refrigerant and heat medium outlet 9 and the support 10, the upper end and the lower end of the cylinder body 2 are respectively connected with the upper head 1 and the lower head 4, forming a shell of a silane intermediate storage tank , the housing is installed on the support 10, the outer wall of the housing is fixedly provided with a coil 3, the lower opening of the coil 3 is a refrigerant and heating medium inlet 8, and the upper opening of the coil 3 is a refrigerant and heating medium Outlet 9 forms the passage of refrigerant and heat medium for cooling and vaporizing sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com