Catalytic crosslinking method for polycarbosilane fiber

A technology of polycarbosilane fiber and cross-linking method, which is applied in the chemical characteristics of fibers, chemical post-treatment of synthetic polymer rayon filaments, textiles and papermaking, etc. Simple process, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

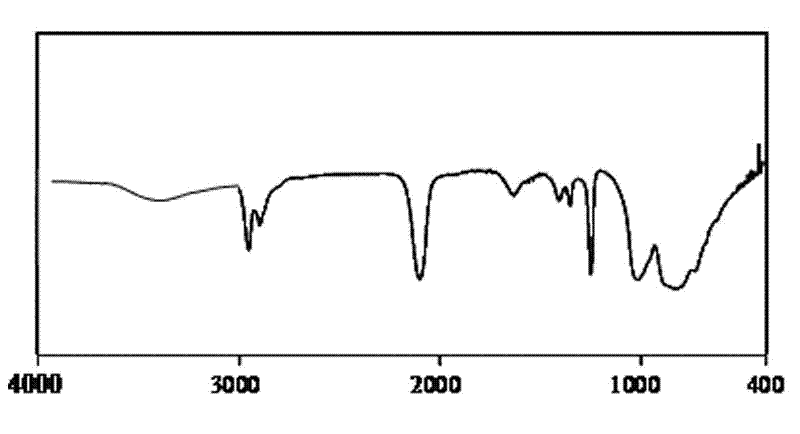

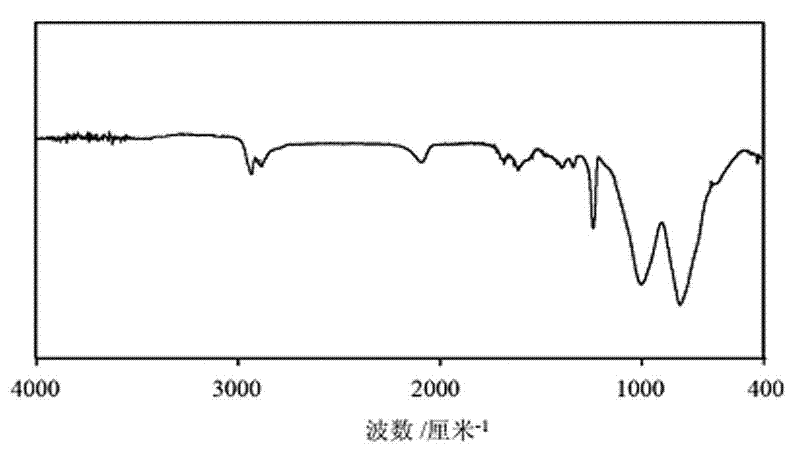

[0032] (1) Preparation of catalyst solution: Dissolve 0.1 g of chloroplatinic acid in 100 mL of deionized water to prepare a catalyst solution; (2) Spin PCS fibrils (FT IR such as figure 1 As shown) the beam slowly passes through the catalyst chloroplatinic acid aqueous solution tank and dries in the air; (3) Place the PCS fibrils containing the catalyst in a chemical vapor phase crosslinking system, vacuumize and fill it with high-purity nitrogen to normal pressure, Repeat 3 times; (4) Introduce 1,3-butadiene gas; (5) Program temperature rise to 180°C, reaction time 6h; (6) Heat up to 450°C, keep warm for 6h, then cool to room temperature to obtain PCS Cross-linked fibers (FT IR as figure 2 shown).

[0033] 2100cm in the FT IR spectrum -1 Si-H absorption peak with 1250cm -1 Si-CH 3 The absorbance ratio of the absorption peak (A Si-H / A Si-CH3 ) to study the Si-H bond content of PCS and crosslinked fibers. From figure 1 The FT IR can calculate the SiH content of PCS f...

Embodiment 2

[0035] (1) Dissolve 0.2g of potassium tetrachloroplatinite in 100mL of deionized water to prepare a catalyst solution; (2) Slowly pass the spun PCS fibril bundles through the tank of potassium tetrachloroplatinite aqueous solution, and dry in the air ; (3) Put the PCS fibrils containing the catalyst potassium tetrachloroplatinite in the chemical vapor phase crosslinking system, fill it with high-purity nitrogen to normal pressure after vacuuming, and repeat three times; (4) Pass 1,4- Pentadiene gas; (5) program temperature rise to 180°C, reaction time 6h; (6) program temperature rise to 450°C, keep warm for 6h, after cooling, PCS cross-linked fiber can be obtained.

[0036] The FT IR spectrogram of gained PCS cross-linked fiber and figure 2 Basically the same, only the intensity of the absorption peak is slightly different. According to the FT IR spectrum, the calculated Si-H bond content of the crosslinked fiber is 0.135, the Si-H bond reaction degree is 85.9%, and the gel ...

Embodiment 3

[0038] (1) Dissolve 0.3g of triphenylphosphine rhodium chloride in 100mL of ethanol to prepare ethanol solution of catalyst triphenylphosphine rhodium chloride; (2) Spray catalyst triphenylphosphine rhodium chloride ethanol solution on (3) place the PCS fibrils containing the catalyst triphenylphosphine rhodium chloride in a chemical vapor phase cross-linking system, and fill it with high-purity nitrogen to normal pressure after vacuuming, Repeat 3 times; (4) Introduce acetylene gas; (5) Program temperature rise to 200°C, reaction time 8h; (6) Program temperature rise to 460°C, keep warm for 8h; PCS crosslinked fiber can be obtained after cooling.

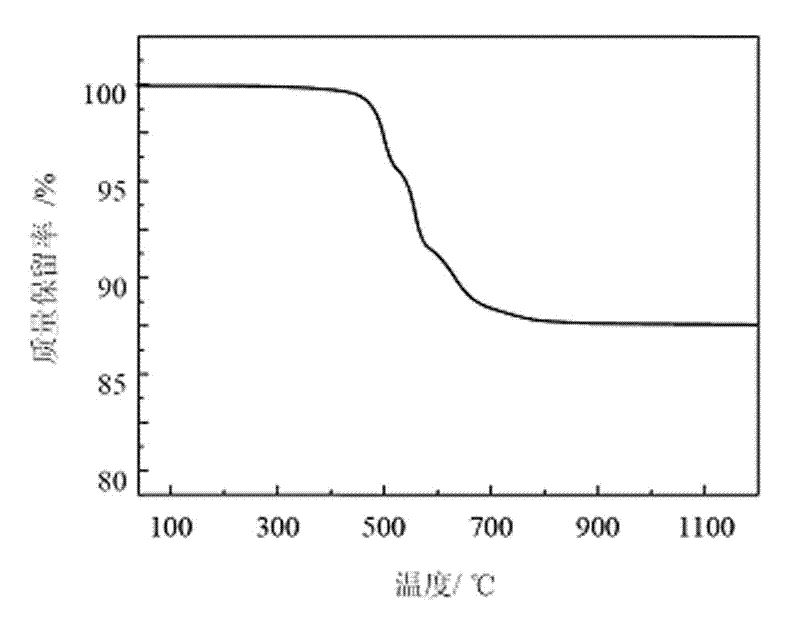

[0039] FT IR spectra of PCS crosslinked fibers and figure 2 Basically the same, only the intensity of the absorption peak is slightly different. According to the FT IR spectrum, the calculated Si-H bond content of the crosslinked fiber is 0.167, the Si-H bond reaction degree is 82.6%, and the gel content is 98.4%. The ceramic yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com