Non-alcoholic monocrystalline silicon flock making additive

A technology of crystalline silicon texturing and additives, applied in the direction of sustainable manufacturing/processing, crystal growth, final product manufacturing, etc., can solve problems such as toxicity, large usage, and fluctuations in photoelectric conversion efficiency, so as to avoid environmental pollution and reduce manufacturing costs. Down cost, the effect of eliminating hydrogen bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

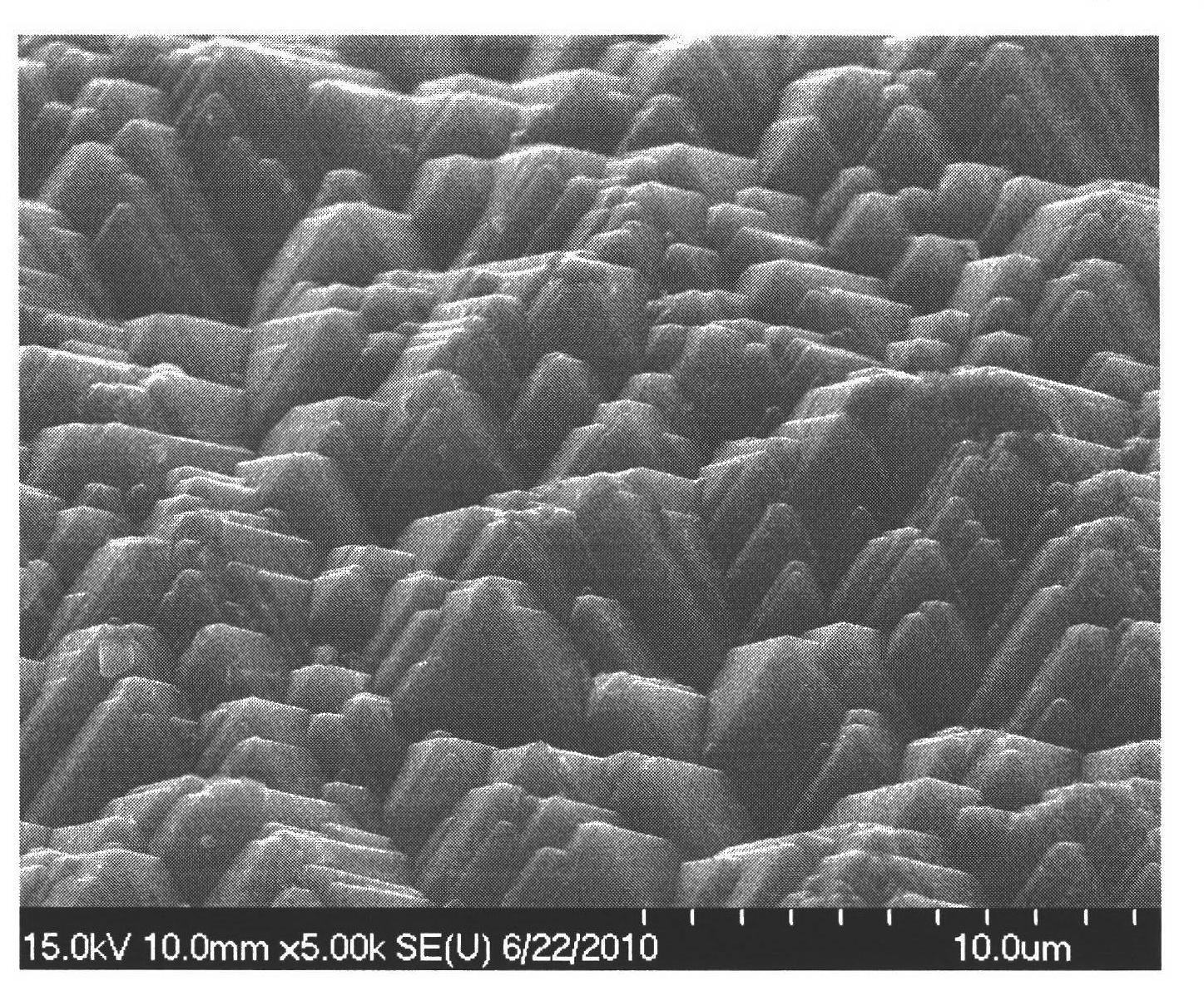

[0018] Example 1. An alcohol-free monocrystalline silicon texturing additive was prepared by using citric acid, sodium dodecylbenzenesulfonate and deionized water. The concentration of citric acid was 3 wt%, and the concentration of sodium dodecylbenzenesulfonate was 2 wt%. Then, the alcohol-free monocrystalline silicon texturing additive is added to the aqueous solution of sodium hydroxide with a concentration of 1.2 wt%, and the volume ratio of the alcohol-free monocrystalline silicon texturing additive in the total solution is 1.0v / v%. Then heat the solution to 80°C, put a single crystal silicon chip with an area of 125 mm x 125 mm and a thickness of about 200 microns into the solution for corrosion and texturing. The corrosion time is 20 minutes, and then the silicon chip is taken out, cleaned, Dry and observe again. The textured pyramids of the resulting silicon wafers are shown in the electron microscope images in the accompanying drawings. It can be seen from the acc...

example 2

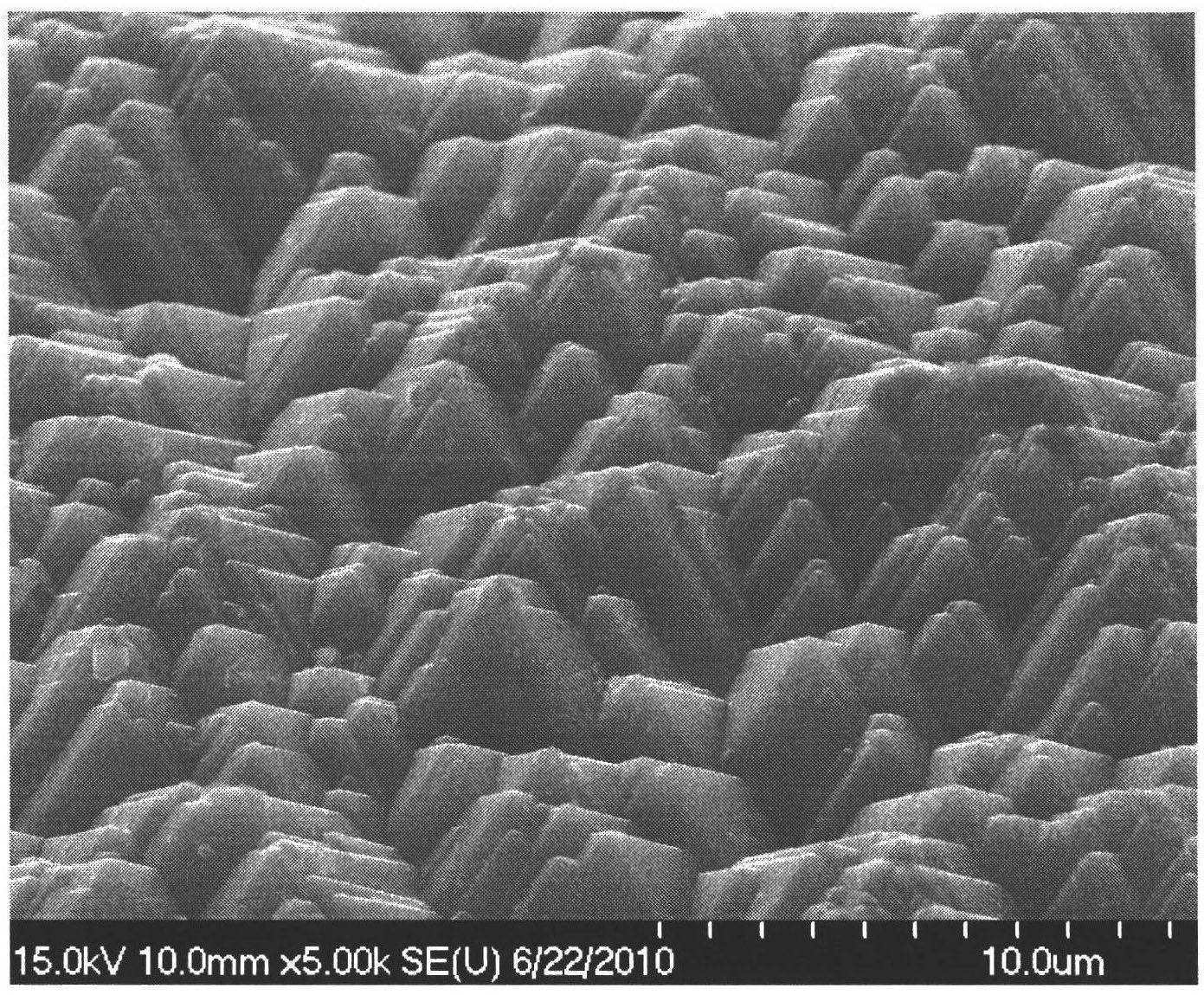

[0019] Example two, using sodium citrate, sodium dodecylbenzenesulfonate and deionized water to prepare alcohol-free monocrystalline silicon texturing additives, the concentration of sodium citrate is 4wt%, and the concentration of sodium dodecylbenzenesulfonate is 1.8 wt%. Then, the alcohol-free monocrystalline silicon texturing additive is added to the aqueous solution of sodium hydroxide with a concentration of 1.2 wt%, and the volume ratio of the alcohol-free monocrystalline silicon texturing additive in the total solution is 1.0v / v%. Then heat the solution to 80°C, put a single crystal silicon chip with an area of 125 mm x 125 mm and a thickness of about 200 microns into the solution for corrosion and texturing. The corrosion time is 20 minutes, and then the silicon chip is taken out, cleaned, Dry and observe again.

example 3

[0020] Example 3. Using sodium citrate, sodium dodecylbenzenesulfonate and deionized water to prepare an alcohol-free monocrystalline silicon texturing additive, the concentration of sodium citrate is 5 wt%, and the concentration of sodium dodecylbenzenesulfonate is 1.5% wt%. Then, the alcohol-free monocrystalline silicon texturing additive is added to the aqueous solution of sodium hydroxide with a concentration of 1.2 wt%, and the volume ratio of the alcohol-free monocrystalline silicon texturing additive in the total solution is 1.0v / v%. Then heat the solution to 80°C, put 200 single-crystal silicon wafers with an area of 125mm×125mm and a thickness of about 200 microns into the solution for etching for 20 minutes, and then take out the silicon wafers. Wash and tumble dry. After adding 150 grams of sodium hydroxide to the solution, put 200 monocrystalline silicon wafers into the solution for texturing. Repeat the above process until 30 batches of monocrystalline silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com