System device for extracting swill-cooked dirty oil as well as application method of extracted swill-cooked dirty oil and swill-cooked dirty oil

A system device and gutter oil technology, applied in chemical instruments and methods, detergent powder/flake/sheet, fatty acid preparation/refining, etc., can solve problems such as damage, reduce pollutant discharge, protect and improve the environment, Beneficial effect on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

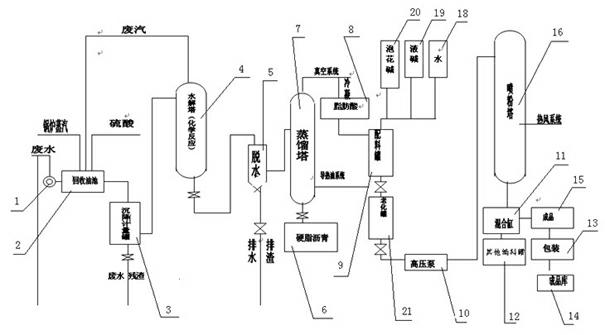

[0021] Reference figure 1 As shown, a system device for refining waste-ditch oil includes a recovery tank, a sedimentation metering tank, a hydrolysis tower, a black fatty acid dehydration tank, a distillation tower system, a fatty acid tank, a soap powder batching tank, an aging tank, a high-pressure pump, Powder spraying tower, heating system, mixing tank, finished product warehouse, packaging finished product warehouse; the waste meal oil and water are pumped into the recycling pool 2 through a water pump or valve 1, and the waste meal oil and water in the recycling pool 2 passes through the precipitated supernatant The sedimentation metering tank 3 sends the supernatant liquid to the hydrolysis tower 4, the hydrolyzed liquid is sent to the black fatty acid dehydration tank 5, the dehydrated black fatty acid is sent to the distillation tower system 7, and the distilled steam passes through the vacuum system and The condenser becomes fatty acid and is sent to the temporary sto...

Embodiment 2

[0023] An application method for extracting waste oil and waste oil from the system device described in the following steps:

[0024] 1). Pour the recovered waste oil and water into the recovery tank and pass it into steam for cooking. When the material is turned over, add 1.5 to 2 parts of sulfuric acid according to the mass ratio of the waste oil and water, and let it continue to cook for 3 to 5 hours, then stop cooking Settling for 2 to 3 hours;

[0025] 2) Take the supernatant liquid and pump it into the sedimentation metering tank 3 equipped with a measuring scale, continue to settle for 5 to 8 hours to drain the sedimentation and residue, and recycle the discharged sedimentation and residue;

[0026] 3). Analyze the acid value of the settled neutral oil, determine the hydrolysis time according to the acid value, and then pour the settled neutral oil into the hydrolysis tower 4 at the ratio of 3 parts to 2 parts according to the oil and water. 4 Heat with steam and increase the...

Embodiment 3

[0033] An application method for extracting waste oil and waste oil from the system device described in the following steps:

[0034] 1). Pour the recovered waste oil and water into the recovery tank and pass it into steam for cooking. When the material is overturned, add 2 parts of sulfuric acid according to the mass ratio of the waste oil and water, let it continue to cook for 5 hours, and then stop cooking for 3 hours;

[0035] 2). Take the supernatant liquid and pump it into the sedimentation metering tank 3 equipped with a measuring scale, continue the sedimentation for 7 hours to drain the sedimentation and residue, and recycle the discharged sedimentation and residue;

[0036] 3). Analyze the acid value of the settled neutral oil, determine the hydrolysis time according to the acid value, and then pour the settled neutral oil into the hydrolysis tower 4 at the ratio of 3 parts to 2 parts according to the oil and water. 4 Heat with steam and increase the pressure for hydrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com