Method for preparing epoxy acrylate modified waterborne polyurethane coating

An epoxy acrylate, water-based polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as low shrinkage rate, and achieve the effects of low shrinkage rate, good physical properties and cold resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

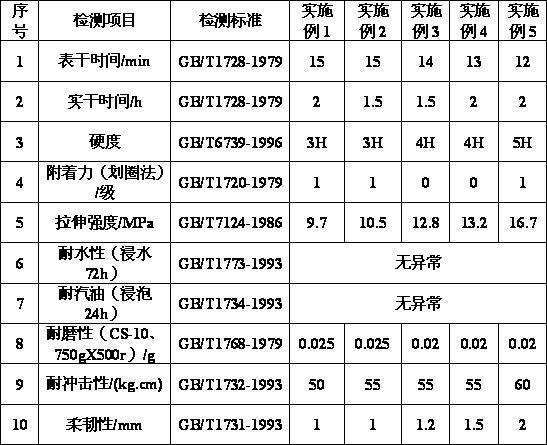

Examples

Embodiment 1

[0024] A). Synthesis of modified epoxy acrylate

[0025] Add 6 parts of epoxy resin E-51, 0.2 parts of polypropylene glycol (PPG600) and 0.002 parts of catalyst dibutyltin dilaurate to the four-necked flask by weight, slowly heat to 80°C, and add 0.01 parts of polymerization inhibition after 15 minutes of reaction Add 0.02 parts of p-methoxyphenol as an agent, add dropwise a mixed solution of 1 part of acrylic acid, 2 parts of butyl acrylate and 0.002 parts of dibutyltin dilaurate as a catalyst, drop it in about 0.5 hours, and slowly raise the temperature to 75°C, every 1 hour Take a sample to measure the acid value once, when the acid value is less than 5mgKOH / g, lower the temperature to obtain low viscosity modified epoxy acrylate;

[0026] B). Preparation of epoxy acrylate modified water-based polyurethane emulsion

[0027] Add 4 parts of methyl-2,4-diisocyanate weighed by weight into a four-necked flask equipped with a stirrer, a thermometer, a condenser tube and ...

Embodiment 2

[0031] A). Synthesis of modified epoxy acrylate

[0032] Add 8 parts by weight of epoxy resin E-51, 0.2 parts of polypropylene glycol (PPG1000) and 0.002 parts of catalyst dibutyltin dilaurate into the four-necked flask, slowly heat to 80 ° C, and add 0.01 parts of polymerization inhibition after 15 minutes of reaction Add 0.02 parts of p-methoxyphenol as an agent, add dropwise a mixed solution of 1 part of acrylic acid, 2 parts of methyl methacrylate and 0.002 parts of dibutyltin dilaurate as a catalyst, finish adding dropwise in about 0.5 hours, and slowly raise the temperature to 86 ° C, every Sampling and measuring the acid value every 1 hour, when the acid value is less than 5mgKOH / g, lower the temperature to obtain low-viscosity modified epoxy acrylate;

[0033] B). Preparation of epoxy acrylate modified water-based polyurethane emulsion

[0034] Add 4 parts of methyl-2,4-diisocyanate by weight to a four-neck flask equipped with a stirrer, thermometer, condenser...

Embodiment 3

[0038] A). Synthesis of modified epoxy acrylate

[0039] Add 7 parts by weight of epoxy resin E-44, 0.3 parts of polypropylene glycol (PPG2000) and 0.003 parts of catalyst dibutyltin dilaurate into a four-neck flask, slowly heat to 80 ° C, and add 0.01 parts of polymerization inhibition after 15 minutes of reaction Add 0.03 parts of p-methoxyphenol as an agent, add dropwise a mixed solution of 2 parts of acrylic acid and 0.003 parts of dibutyltin dilaurate as a catalyst, finish adding dropwise for 0.5 hours, slowly raise the temperature to 88°C, and measure the acid value once every 1 hour. When the acid value is less than 5mgKOH / g, lower the temperature to obtain low-viscosity modified epoxy acrylate;

[0040] B). Preparation of epoxy acrylate modified water-based polyurethane emulsion

[0041] TM Add 6 parts by weight of methyl-2,4-diisocyanate to a four-necked flask equipped with a stirrer, a thermometer, a condenser tube and a nitrogen conduit, and add the modifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com