Furfural-free environment-friendly type high-seepage epoxy waterproof reinforcing paint as well as preparation method and application thereof

An environmentally friendly technology for reinforcing coatings, applied in epoxy resin coatings, building insulation materials, coatings, etc., can solve the problems of material permeability and mechanical strength, and achieve aging resistance, cost-effective, simple operation, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

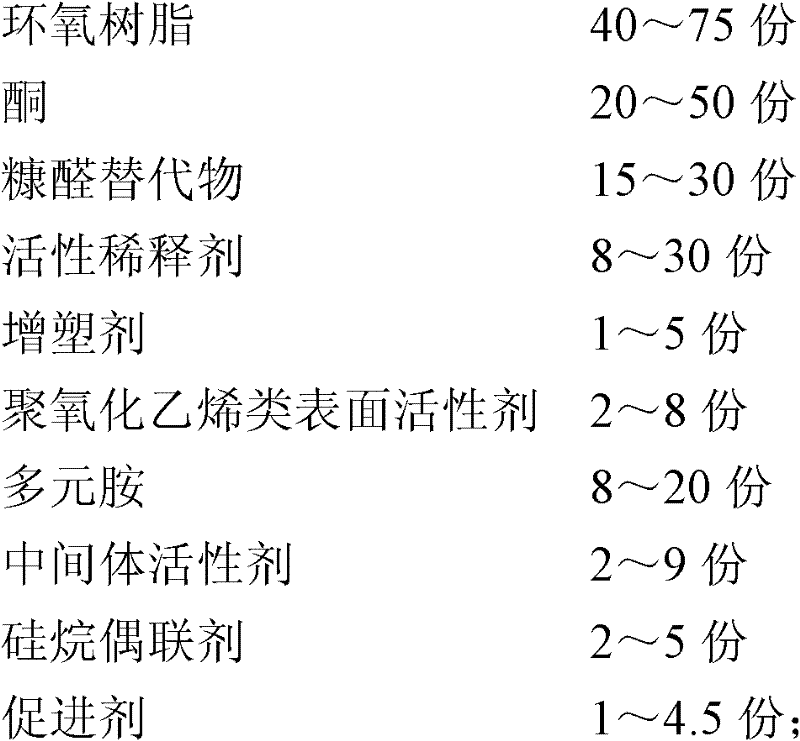

Method used

Image

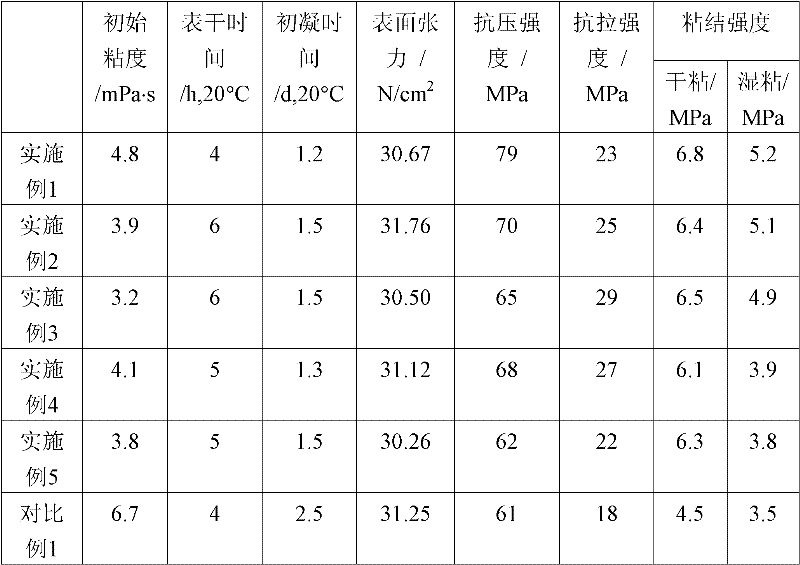

Examples

Embodiment 1

[0033] (1) Add 1 mol of adipic acid, 1 mol of triethylenetetramine and 1 mol of tetraethylenepentamine to a three-necked flask equipped with a stirring device and a condensing device, gradually raise the temperature to 180°C, and react at a constant temperature for 2 hours under stirring; After the distilled water was produced, the temperature was slowly lowered to 50-60°C, and the stirring was continued and the reaction was carried out at constant temperature for 1 hour. Finally stop heating and cool to room temperature to obtain the intermediate active agent.

[0034] (2) 50 mass parts E-44 epoxy resin, 20 mass parts benzaldehyde, 20 mass parts acetone, 10 mass parts butyl glycidyl ether, 5 mass parts 1,4-butanediol diglycidyl ether, 2 Parts by mass of ethylene glycol and 2 parts by mass of polyoxyethylene pentylphenol ether were added into the reactor and stirred for 20 minutes to obtain the main agent A liquid after uniformity.

[0035] (3) Add 10 parts by mass of diethyl...

Embodiment 2

[0038] (1) 40 parts by mass of E-44 epoxy resin, 30 parts by mass of anisaldehyde, 20 parts by mass of acetone, 10 parts by mass of butanone, 5 parts by mass of butyl glycidyl ether, 3 parts by mass of 1,4-butanediol Diglycidyl ether, 1 mass part of ethylene glycol and 2 mass parts of polyoxyethylene pentylphenol ether were added into the reactor and stirred for 20 minutes to obtain the main agent A liquid after uniformity.

[0039] (2) 8 parts by mass of diethylenetriamine, 5 parts by mass of intermediate activator (prepared by Example 1 step (1)), 2 parts by mass of γ-aminopropyltriethoxysilane and 1 part by mass of N , N-dimethylaniline, added to the reactor and stirred for 20 minutes, and the main agent B liquid was obtained after uniformity.

[0040] (3) When using, mix the main agent A and the main agent B to obtain a furfural-free environmentally friendly high-permeability epoxy waterproof reinforcing coating, which can be directly painted on the treatment surface.

Embodiment 3

[0042] (1) with 60 mass parts E-51 epoxy resin, 25 mass parts cinnamaldehyde, 20 mass parts butanone, 10 mass parts butyl glycidyl ether, 5 mass parts 1,4-butanediol diglycidyl ether, Add 2 parts by mass of ethylene glycol and 2 parts by mass of polyoxyethylene pentylphenol ether into the reactor and stir for 20 minutes to obtain the main agent A liquid after being uniform.

[0043] (2) With 15 parts by mass of diethylenetriamine, 9 parts by mass of intermediate active agent (prepared according to Example 1 step (1), 3 parts by mass of γ-aminopropyltriethoxysilane and 1 part by mass of N , N-dimethylaniline, added to the reactor and stirred for 20 minutes, and the main agent B liquid was obtained after uniformity.

[0044] (3) When in use, mix main agent A and main agent B to obtain a furfural-free environmentally friendly high-permeability epoxy waterproof reinforcing coating, which can be directly painted on the treated surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com