Coating-free polypropylene composition with paint brightness and metal texture and preparation method thereof

A polypropylene composition and metal texture technology, applied in the field of modified plastics, can solve the problems of no metal effect, no paint gloss, easy residual monomers in the paint, etc., and achieve good paint gloss and metal texture, The effect of simplified process and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

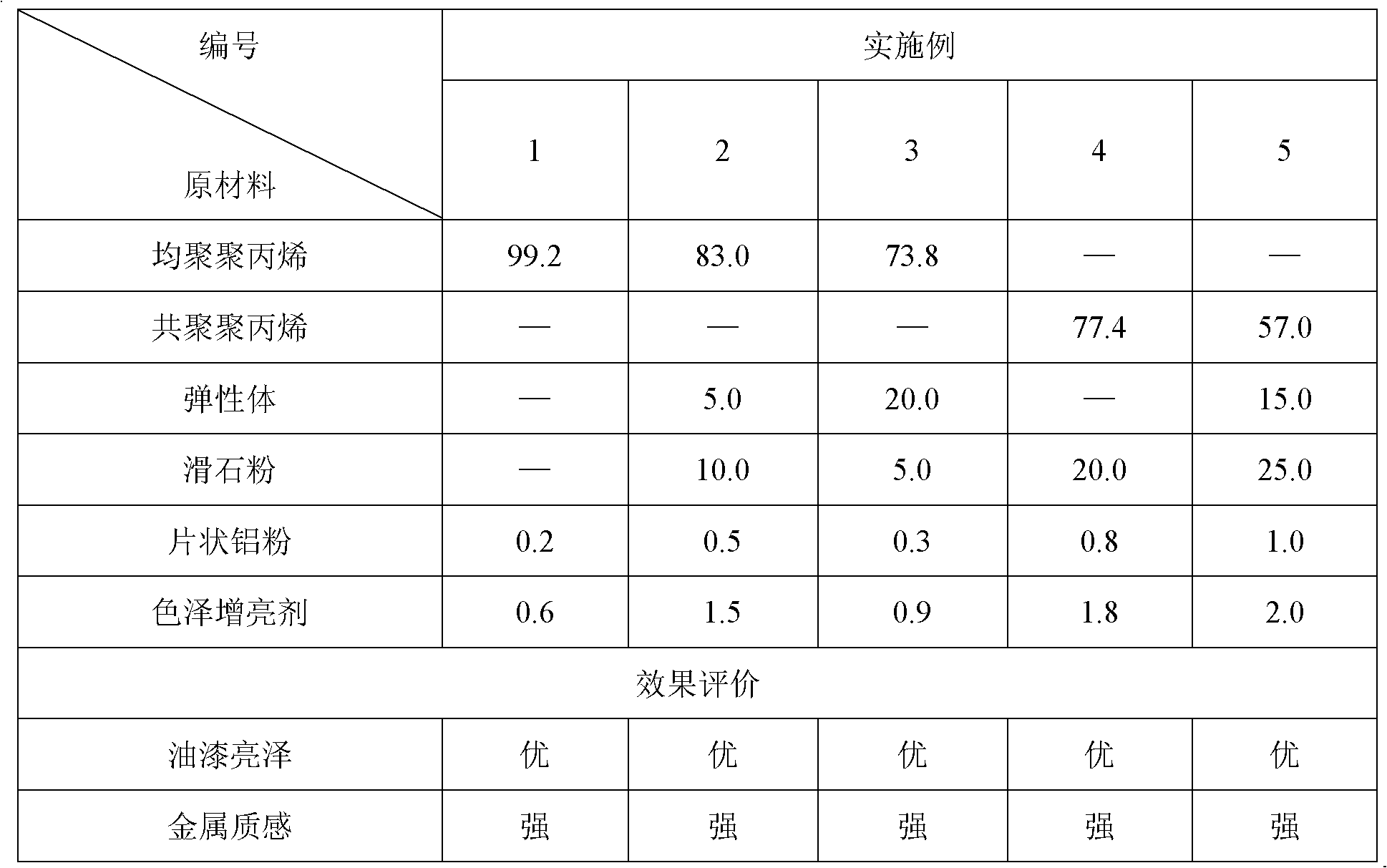

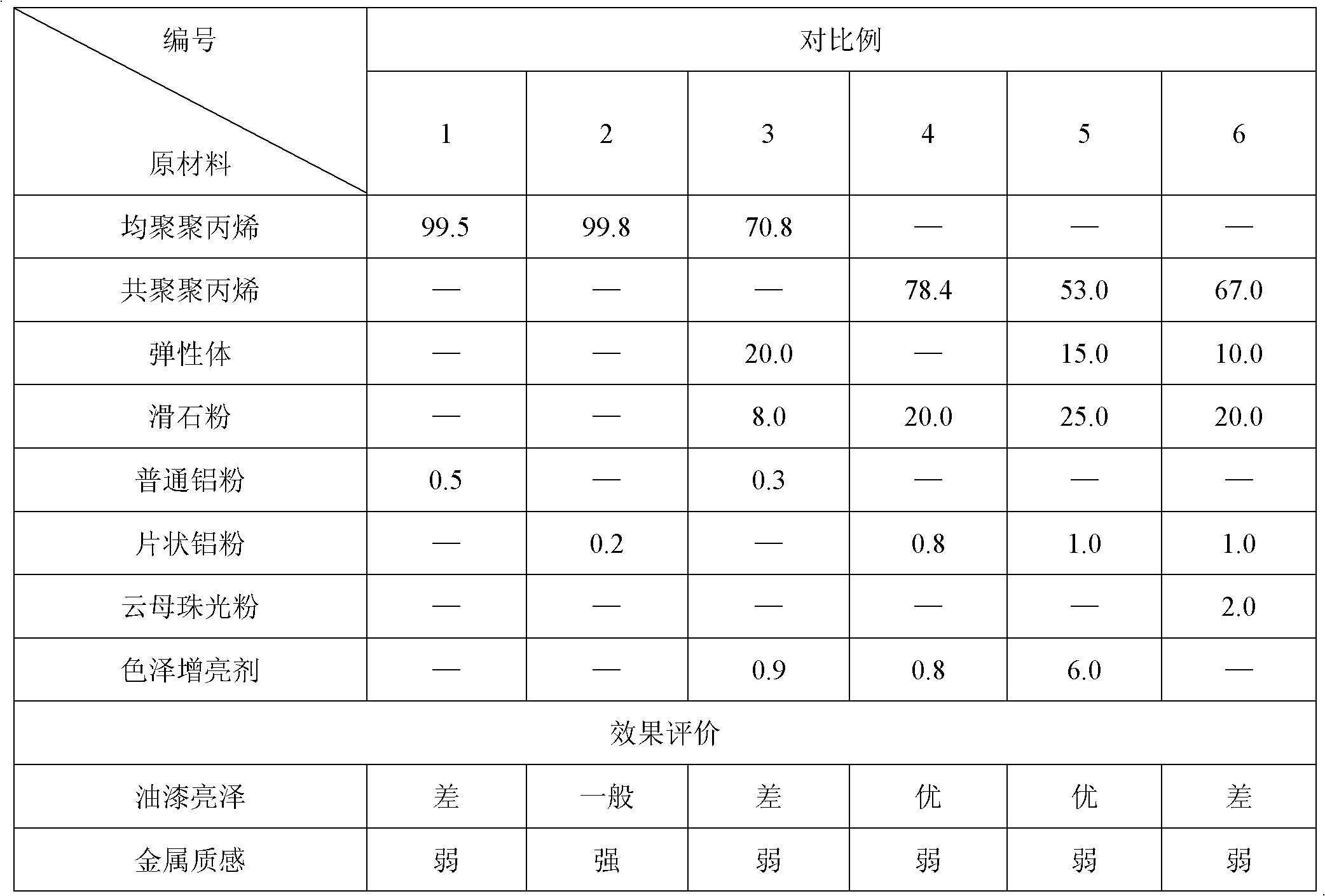

[0038] A spray-free polypropylene composition with a glossy metallic texture of paint, prepared by the following method:

[0039] According to the formula in Table 1, homopolypropylene, flaky aluminum powder (with a particle size of 5 μm), and titanium dioxide-coated mica (with a purity of 95% and a particle size of 10 μm) were weighed. Mix homopolypropylene, flake aluminum powder, and titanium dioxide-coated mica in a mixer for 1 to 3 minutes at a speed of 800 to 1500 rpm to obtain a premix; the premix is melted by a twin-screw extruder Extrusion, the temperature of each zone of the screw is 190-250 ℃, and vacuum granulation to make polypropylene with glossy paint and no spraying.

[0040] Evaluate the paint luster and metallic texture of the injection molded samples, and the specific evaluation grades are listed in Table 1.

Embodiment 2

[0042] A spray-free polypropylene composition with a glossy metallic texture of paint, prepared by the following method:

[0043] According to the formula in Table 1, homopolypropylene, ethylene-propylene copolymer, talcum powder, flake aluminum powder (50 μm in particle size), and mica coated with titanium dioxide (98% in purity and 50 μm in particle size) were weighed. Mix polypropylene and elastomer in a high mixer for 1 to 3 minutes, then add talcum powder, flake aluminum powder, titanium dioxide-coated mica and mix for 1 to 3 minutes at a speed of 800 to 1500 rpm to obtain The premixed material is melted and extruded by a twin-screw extruder, and the temperature of each zone of the screw is 190-250 ° C. Vacuum granulation is used to obtain the glossy and spray-free polypropylene.

[0044] Evaluate the paint luster and metallic texture of the injection molded samples, and the specific evaluation grades are listed in Table 1.

Embodiment 3

[0046] A spray-free polypropylene composition with a glossy metallic texture of paint, prepared by the following method:

[0047] According to the formula in Table 1, homopolypropylene, ethylene-octene copolymer, talcum powder, flake aluminum powder (100 μm in particle size), and titanium dioxide-coated mica (98% in purity and 80 μm in particle size) were weighed. The mixing method and preparation method were the same as in Example 2, and the paint gloss and metallic texture of the injection molded samples were evaluated, and the specific evaluation grades were listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com