Photoelectric active dithiophene benzodithiophene conjugated polymer and preparation method and application thereof

A polymer and group technology, used in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of molecular structure research and application that have not yet been reported, and achieve the effect of high photoelectric conversion efficiency and good hole mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

[0060] Example 1, 2,6-bis(trimethyltin base)-4,8-bis(2-hexyldecyl)-dithieno[2,3-d:2',3'-d']benzene Synthesis of [1,2-b:4,,5-b']dithiophene (7)

[0061] chemical reaction flow chart Figure 7 Shown, concrete reaction steps and reaction conditions are as follows:

[0062]Compound 2: Compound 1 (4mmol, 2.7g) was dissolved in chloroform (30ml), and liquid bromine (24mmol, 3.8g) in chloroform (20ml) was added dropwise at room temperature. After all the dropwise addition was completed, the mixture was stirred at room temperature for 20 hours. After the reaction was completed, the reaction solution was poured into 200 mL of saturated sodium thiosulfate solution. The organic phase of the mixture was extracted twice with chloroform, and the two extracted organic phases were combined for drying over anhydrous magnesium sulfate. Column chromatography with petroleum ether eluent gave the product as a white solid (3.52 g, 89%) after removal of the solvent.

[0063] 1 H NMR (400MHz, C...

Embodiment 2

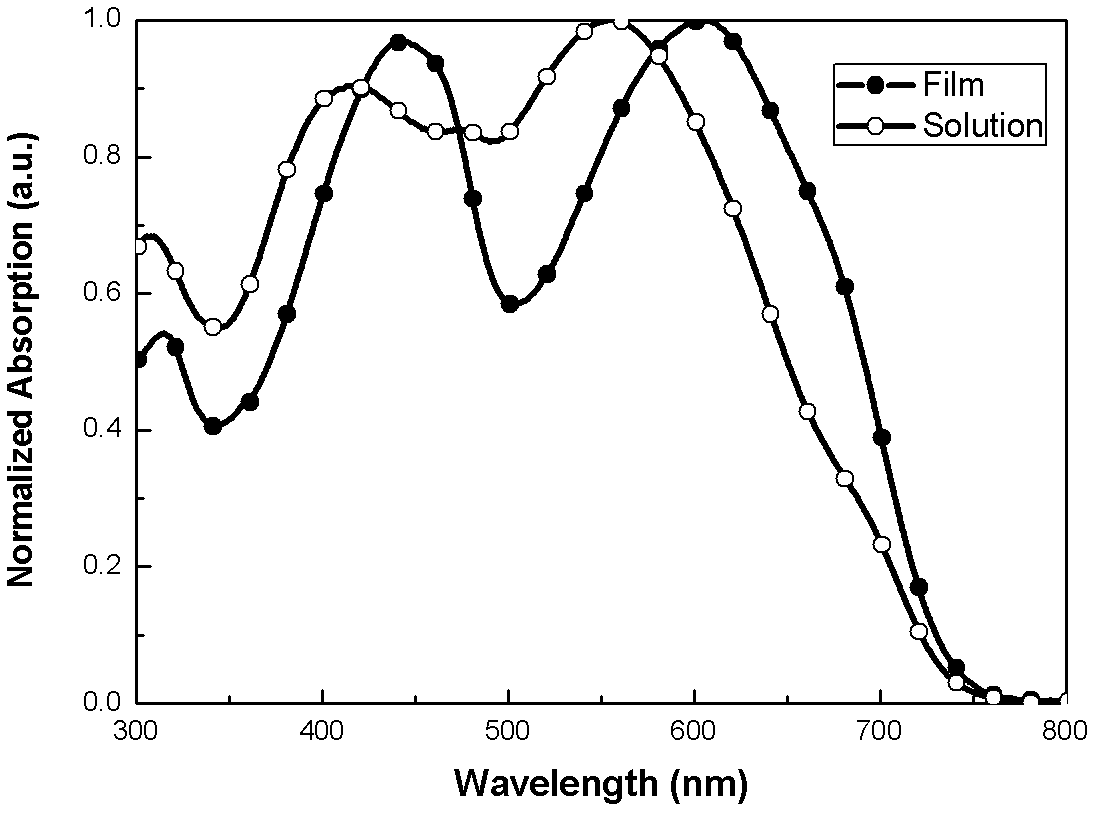

[0073] Example 2, poly{[4,8-bis(2-hexyldecyl)-dithieno[2,3-d:2′,3′-d′]benzo[1,2-b:4, ,5-b′]dithiophene]-co-[4,7-bis(5-(2-ethylhexyl)thiophen-2-yl)benzo[1,2,5]thiadiazole} (polymer Synthesis of PDTBDT-DTBT)

[0074] chemical reaction flow chart Figure 8 Shown, concrete reaction steps and reaction conditions are as follows:

[0075] Take the monomer 2,6-bis(trimethyltinyl)-4,8-bis(2-hexyldecyl)-dithieno[2,3-d:2′,3′-d′]benzo [1,2-b:4,,5-b']dithiophene (7) (0.555 g, 0.5 mmol) and the monomer 4,7-bis(5-bromo-4-(2-ethylhexyl)thiophene -2-yl) benzo[1,2,5]thiadiazole (0.341g, 0.5mmol), after dissolving it in toluene (25mL), exhaust the air with argon for 5 minutes, then add the catalyst tetrakis(triphenyl phosphine)palladium(0) (25 mg) and continued to evacuate the air for 25 minutes. Polymerization was then stopped after 14 hours at the reflux temperature of toluene. The polymer solution was cooled to room temperature, slowly poured into methanol (50 mL), and the precipitated ...

Embodiment 3

[0076] Example 3, poly{[4,8-bis(2-hexyldecyl)-dithieno[2,3-d:2′,3′-d′]benzo[1,2-b:4, ,5-b']dithiophene]-co-5-(2-ethylhexyl)-4H-thieno[3,4-c]pyrrole-4,6(5H)-dione}(polymer PBDF- Synthesis of Th-TPD)

[0077] chemical reaction flow chart Figure 9 Shown, concrete reaction steps and reaction conditions are as follows:

[0078] Take the monomer 2,6-bis(trimethyltin base)-4,8-bis(2-hexyldecyl)-dithieno[2,3-d2',3'-d']benzo[1 ,2-b: 4,,5-b′]dithiophene (7) (0.218g, 0.25mmol) and the monomer 1,3-dibromo-5-(2-ethylhexyl)-4H-thieno[ 3,4-c]pyrrole-4,6(5H)-dione (TPD, 0.105g, 0.25mmol), after dissolving it in a mixed solvent of toluene (8mL) and DMF (2mL), exhaust the air with argon After 5 minutes, the catalyst tetrakis(triphenylphosphine)palladium(0) (20 mg) was added and the air was continued to be exhausted for 25 minutes. Polymerization was then stopped after 15 hours at the reflux temperature of toluene. The polymer solution was cooled to room temperature, slowly poured into me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com