Method for preparing thermoset phenolic resin and method for preparing conductive slurry

A technology of phenolic resin and phenolic resin solution, which is applied in the field of preparation of low-temperature conductive paste, thermosetting phenolic resin, and phenolic resin. rate, the effect of increasing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

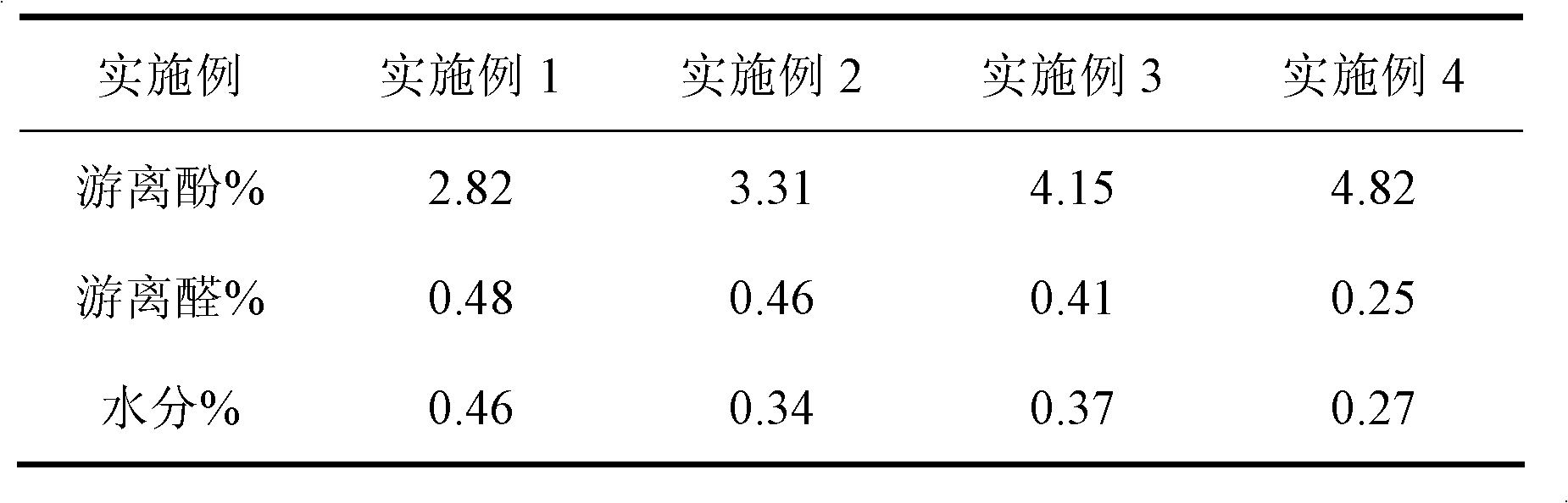

[0035]Add 40 grams of phenol, 41.4 grams of 37% formaldehyde, 0.85 grams of sodium hydroxide and 1.81 grams of barium hydroxide in the reaction bottle, and react at a constant temperature of 60°C for 5 hours, then add 27.6 grams of 37% formaldehyde and react at a constant temperature of 60°C After 5 hours, 4.17 g of 50% sulfuric acid was added for 10 minutes of neutralization reaction, and then 60 g of cyclohexanone and 20 g of toluene were added for extraction and washed twice with water, and the water phase was removed. The solution was transferred to a new reaction vial and vacuum desolvated at 115°C for 1.5 hours. Finally, ethylene glycol monobutyl ether is added for dissolution to obtain a thermosetting phenolic resin solution with a solid content of about 70%. Described phenolic resin is carried out the mensuration of free phenol, free formaldehyde and water content, and its result is shown in Table 1. Use the thermosetting phenolic resin solution as a bonding material,...

Embodiment 2

[0037] Add 40 grams of phenol, 41.4 grams of 37% formaldehyde, 0.85 grams of sodium hydroxide and 0.62 grams of magnesium hydroxide in the reaction flask, and react at a constant temperature of 70 °C for 4 hours, then add 20.7 grams of 37% formaldehyde and react at a constant temperature of 70 °C 4h, 7.76 g of 20% hydrochloric acid was added for 10 minutes of neutralization reaction, and then 80 g of cyclohexanone was added for extraction and washed twice with water, and the water phase was removed. The solution was transferred to a new reaction vial and vacuum desolvated at 110°C for 1.5 hours. Finally, ethylene glycol butyl ether acetate was added for dissolution to obtain a thermosetting phenolic resin solution with a solid content of 70%. Described phenolic resin is carried out the mensuration of free phenol, free formaldehyde and water content, and its result is shown in Table 1. Use the thermosetting phenolic resin solution as the bonding material, adopt conductive carb...

Embodiment 3

[0039] Add 40 grams of phenol, 34.51 grams of 37% formaldehyde, 0.6 grams of potassium hydroxide and 1.23 grams of barium hydroxide in the reaction bottle, and react at a constant temperature of 90 ° C for 3 hours, then add 20.7 grams of 37 % formaldehyde and react at a constant temperature of 90 ° C 3h, 3.13g of 50% sulfuric acid was added for 10 minutes of neutralization reaction, then 80g of cyclohexanone was added for extraction and washed twice with water, and the water phase was removed. The solution was transferred to a new reaction vial and vacuum desolvated at 108°C for 1.5 hours. Finally, diethylene glycol monomethyl ether is added for dissolution to obtain a thermosetting phenolic resin solution with a solid content of about 70%. Described phenolic resin is carried out the mensuration of free phenol, free formaldehyde and water content, and its result is shown in Table 1. Use the thermosetting phenolic resin solution as the bonding material, adopt the silver-coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com