Process for coproducing melamine and ammonium sulfate

A technology of melamine and ammonium sulfate, applied in ammonia compounds, inorganic chemistry, organic chemistry and other directions, can solve the problems of steam entrained ammonia gas and acid mist environmental pollution, large steam consumption and high production cost, and achieves significant economic benefits and equipment investment. Less, the effect of production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

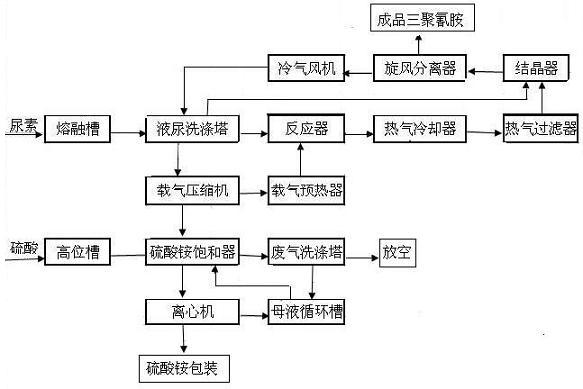

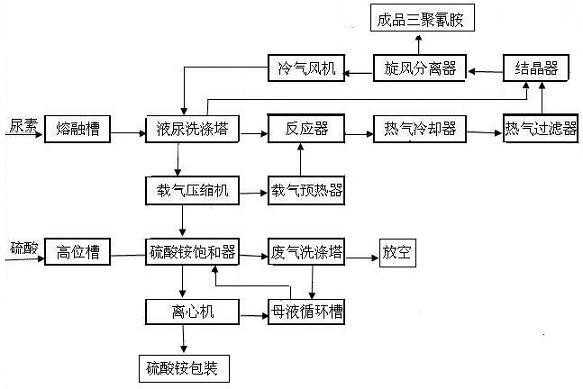

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

[0008] Such as figure 1 As shown, the raw material urea is sent into the urea melting tank, heated and melted by 0.45MPa saturated steam, the melted urea enters the liquid urine washing tower, and is mixed with the high-temperature liquid urine coming down from the washing tower, and the mixed liquid urine is boosted by the liquid urine pump It is divided into two routes: one route is sent to the fluidized bed reactor through the nozzle as the reaction raw material, and the other route is cooled to 132-136°C by the liquid urine cooler and enters the top of the liquid urine washing tower, where it is contacted with the circulating gas for washing and cooling. The liquid urine that enters the reactor after being pressurized by the liquid urine pump reacts to generate melamine under the high temperature of 0.12-0.20MPa and 380-390°C through the action of a catalyst. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com