Synthetic method of (ethoxymethylene)-malononitrile

A technology of ethoxymethylene malononitrile and synthesis method, which is applied in chemical instruments and methods, preparation of carboxylic acid nitrile, preparation of organic compounds, etc., can solve the problems of large amount of organic solvent, high reaction temperature, and yield of target product. Unsatisfactory efficiency and purity, etc., to achieve the effects of improving purity, lowering reaction temperature, and lowering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

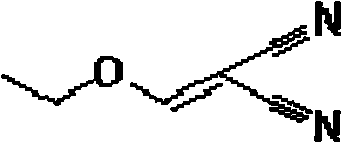

Image

Examples

Embodiment 1

[0026] 1) Preparation of ethoxymethylene malononitrile:

[0027] In a 5000ml three-neck flask, install a thermometer, a condenser, and a mechanical stirrer, add 2600g of triethyl orthoformate, cool in an ice-water bath to about 20°C, and drop 1050g of malononitrile quickly and intermittently, without obvious heat release, drop after 30 minutes After the addition is complete, 10 g of anhydrous zinc chloride is added, heated in a water bath to 70° C., and stirred for 3 h. After the reaction, the ethanol generated by the reaction was distilled off, and a dark red solid was obtained after cooling. After crystallization in refrigeration, suction filtration was obtained to obtain the crude product of ethoxymethylene malononitrile (directly proceed to the next step of refining without drying).

[0028] 2) Refining of ethoxymethylene malononitrile:

[0029] Add the above crude product of ethoxymethylenemalononitrile into a 5000ml three-necked flask, install a thermometer, condenser, ...

Embodiment 2

[0031] 1) Preparation of ethoxymethylene malononitrile:

[0032] In a 5000ml three-necked bottle, install a thermometer, a condenser, and a mechanical stirrer. Add 2,600g of triethyl orthoformate, cool in an ice-water bath to about 20°C, add 1,100g of malononitrile intermittently and rapidly, without obvious exotherm, and complete the dropwise addition after 50 minutes, then add 10g of anhydrous zinc chloride, and heat in a water bath to 70 ° C, stirring the reaction for 2.5h. After the reaction, the ethanol generated by the reaction was distilled off, and a dark red solid was obtained after cooling. After crystallization in refrigeration, suction filtration was obtained to obtain the crude product of ethoxymethylene malononitrile (no drying, directly proceed to the next step of refining).

[0033] 2) Refining of ethoxymethylene malononitrile:

[0034] Add the above crude product of ethoxymethylenemalononitrile into a 5000ml three-necked flask, install a thermometer, condens...

Embodiment 3

[0036] 1) Preparation of ethoxymethylene malononitrile:

[0037] In a 5000ml three-necked bottle, install a thermometer, a condenser, and a mechanical stirrer. Add 2600g of triethyl orthoformate, cool in an ice-water bath to about 20°C, add 1160g of malononitrile intermittently and quickly, without obvious exotherm, and complete the dropwise addition after 40 minutes, then add 11g of anhydrous zinc chloride, and heat in a water bath to 70 ° C, stirring the reaction for 4h. After the reaction, the ethanol generated by the reaction was distilled off, and a dark red solid was obtained after cooling. After crystallization in refrigeration, suction filtration was obtained to obtain the crude product of ethoxymethylene malononitrile (no drying, directly proceed to the next step of refining).

[0038] 2) Refining of ethoxymethylene malononitrile:

[0039] Add the above crude product of ethoxymethylenemalononitrile into a 5000ml three-necked flask, install a thermometer, condenser, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com