Fireproof material, preparation method thereof and fireproof door

A fireproof material and fireproof board technology, applied in the field of fireproof doors, can solve the problems of short fire resistance time, easy to jump fire, poor heat insulation performance, etc., and achieve the effects of long fire resistance time, low production cost and high fire resistance temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

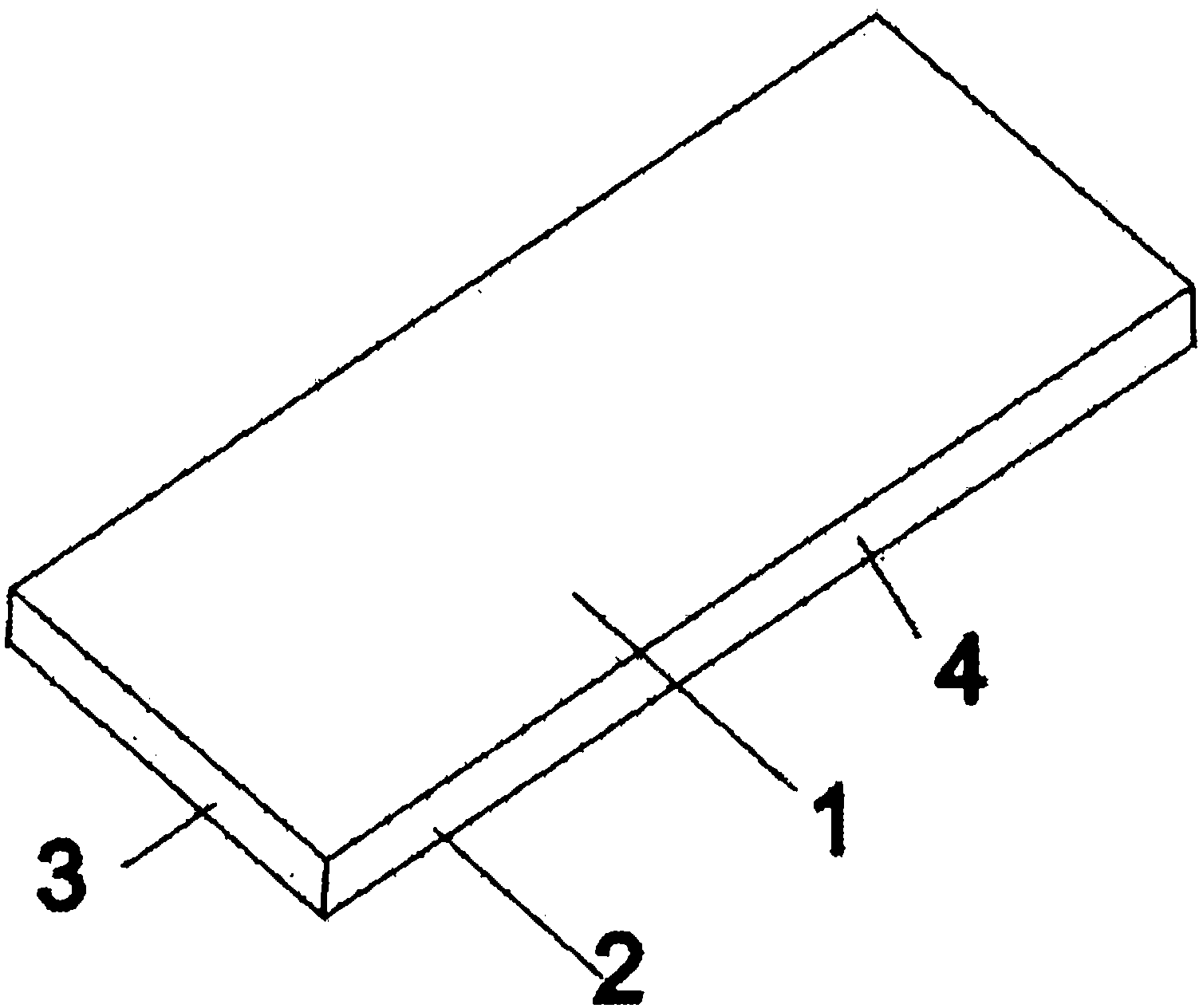

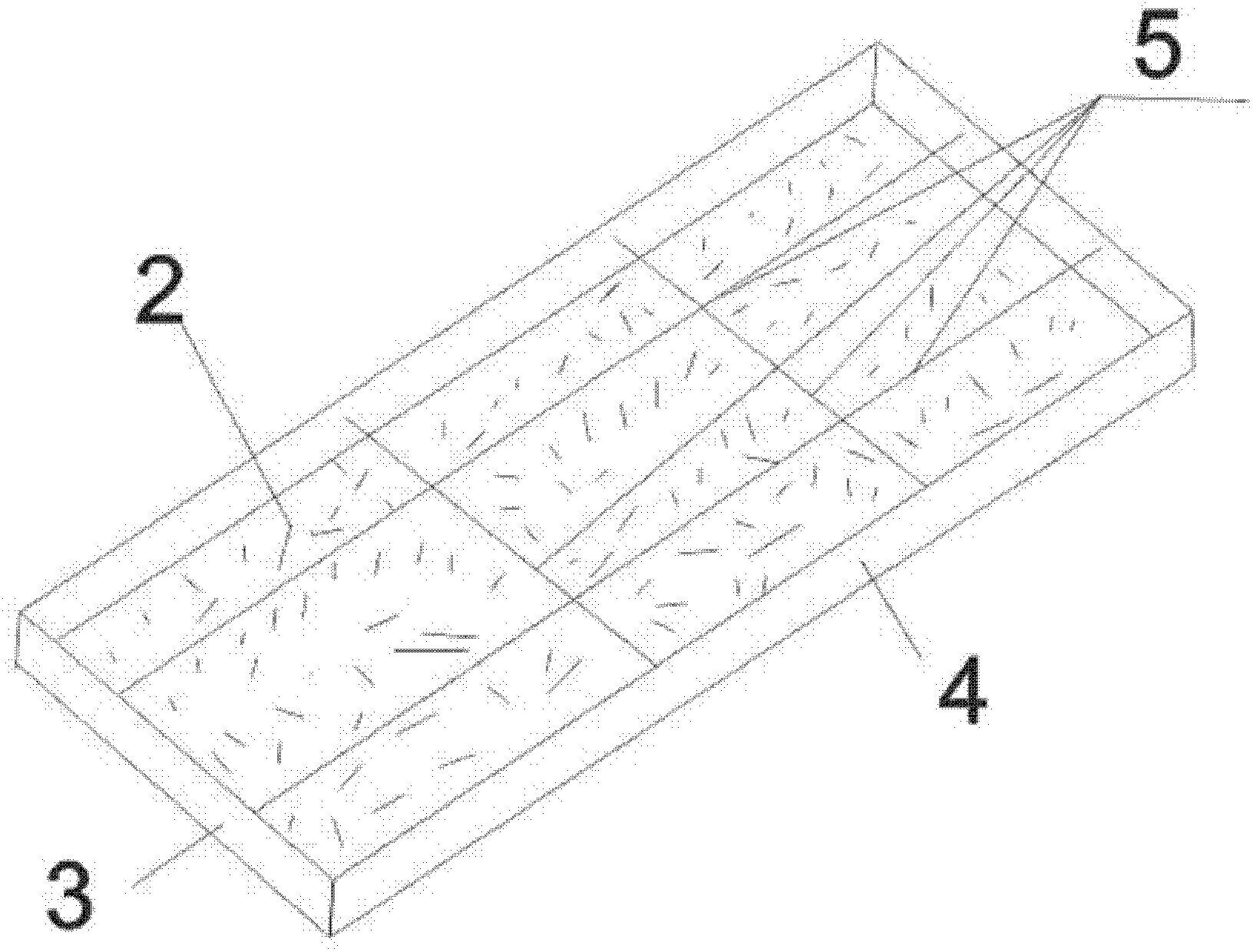

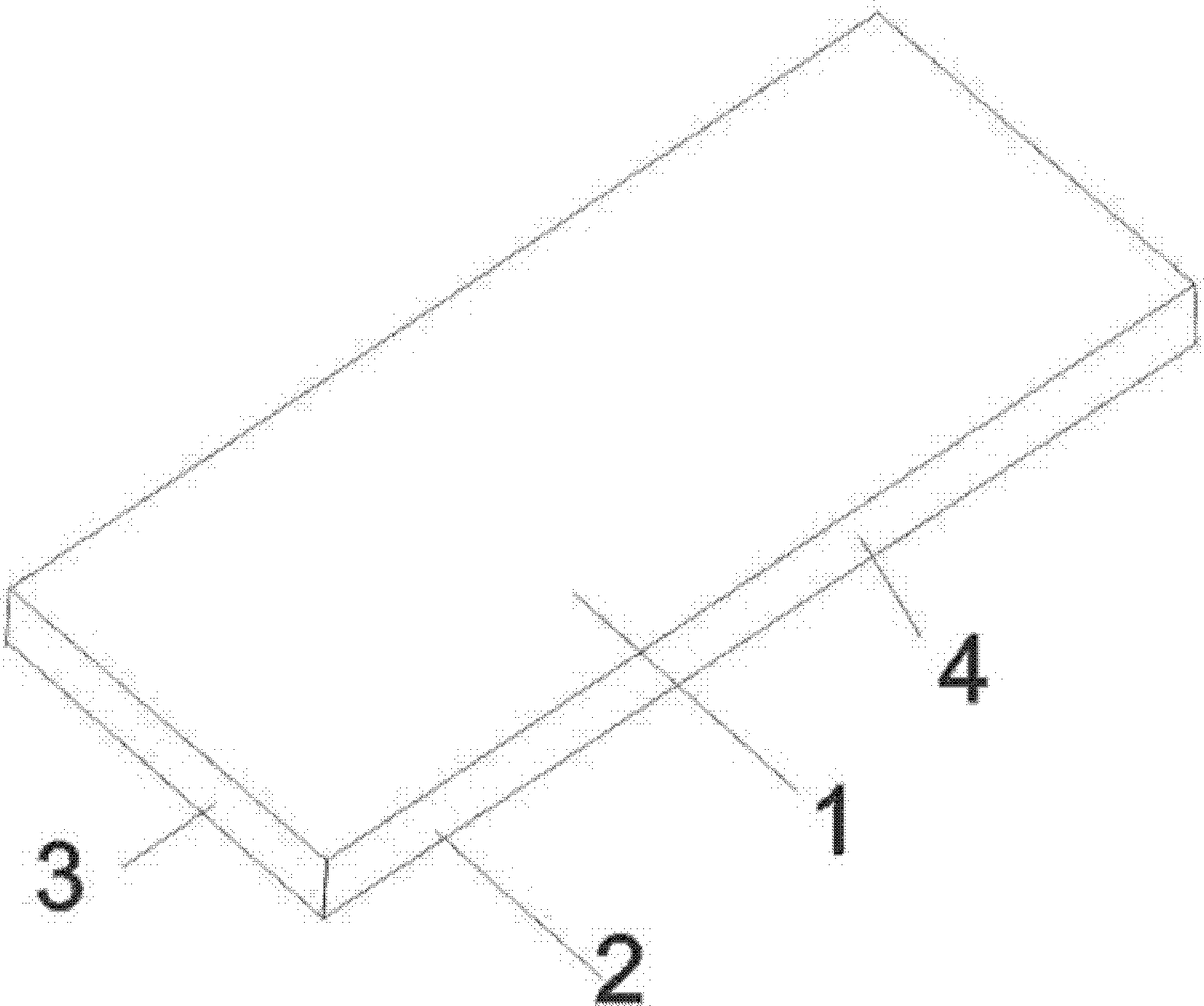

[0027] 1: Install the 3-8mm thick fireproof board backfire panel 2 and the rectangular edge banding frame (including the left and right side panels 4 and the front and rear side panels 3, and the front and rear side panels 3 are equivalent to the door. rear top edge and bottom edge) to form an open blank fire door leaf, a cavity is formed between the back fire panel 2 of the fireproof board and the rectangular edge sealing frame, and between the front and rear side panels 3 Pull two carbon fiber ropes 5, and the two ends of the two carbon fiber ropes 5 are respectively fixed on the middle part of the front and rear side panels 3, and two carbon fiber ropes 5 are also pulled between the left and right side panels 4. Two ends of a carbon fiber rope 5 are respectively fixed in the middle of the left and right side panels 3, and the four carbon fiber ropes 5 form a "#" shape. The carbon content of the carbon fiber rope is 95%-98%, the ash content is less than 0.5%, the maximum tem...

Embodiment 2

[0034] 1: Install the 3-8mm thick fireproof board backfire panel 2 and the rectangular edge banding frame (including the left and right side panels 4 and the front and rear side panels 3, and the front and rear side panels 3 are equivalent to the door. rear top edge and bottom edge) to form a blank fire door leaf, a cavity is formed between the back fire panel 2 of the fireproof board and the rectangular edge sealing frame, and three Aluminum silicate refractory fiber rope 5, the two ends of the three aluminum silicate refractory fiber ropes 5 are respectively fixed in the middle of the front and rear side panels 3, and three aluminum silicate refractory ropes are also connected between the left and right side panels 4. Fiber ropes 5, the two ends of the three aluminum silicate refractory fiber ropes 5 are respectively fixed in the middle of the left and right side plates 3, and the six carbon fibers 5 form a grid shape.

[0035] 2. Clean the mixer, and add 70 parts of black m...

Embodiment 3

[0041] 1: Install the 3-8mm thick fireproof board backfire panel 2 and the rectangular edge banding frame (including the left and right side panels 4 and the front and rear side panels 3, and the front and rear side panels 3 are equivalent to the door. rear top edge and bottom edge) to form an open blank fire door leaf, a cavity is formed between the back fire panel 2 of the fireproof board and the rectangular edge sealing frame, and between the front and rear side panels 3 Pull two carbon fiber ropes 5, and the two ends of the two carbon fiber ropes 5 are respectively fixed on the middle part of the front and rear side panels 3, and two carbon fiber ropes 5 are also pulled between the left and right side panels 4. Two ends of a carbon fiber rope 5 are respectively fixed in the middle of the left and right side panels 3, and the four carbon fiber ropes 5 form a "#" shape. The carbon content of the carbon fiber rope is 95%-98%, the ash content is less than 0.5%, the maximum tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com