Vulcanizing-packaging method for polytetrafluoroethylene hose assembly and vulcanizing-packaged polytetrafluoroethylene hose assembly

A technology of polytetrafluoroethylene and hose components, which is applied in the direction of hoses, pipes/pipe joints/fittings, pipes, etc., can solve the problems of low fire resistance temperature, and achieve high fire resistance temperature, light fire resistance and high temperature resistance, and air tightness Good performance and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

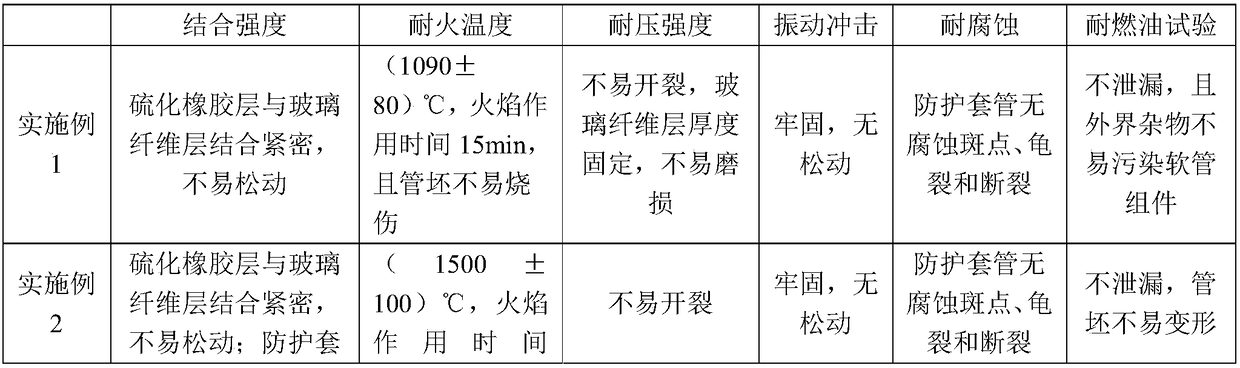

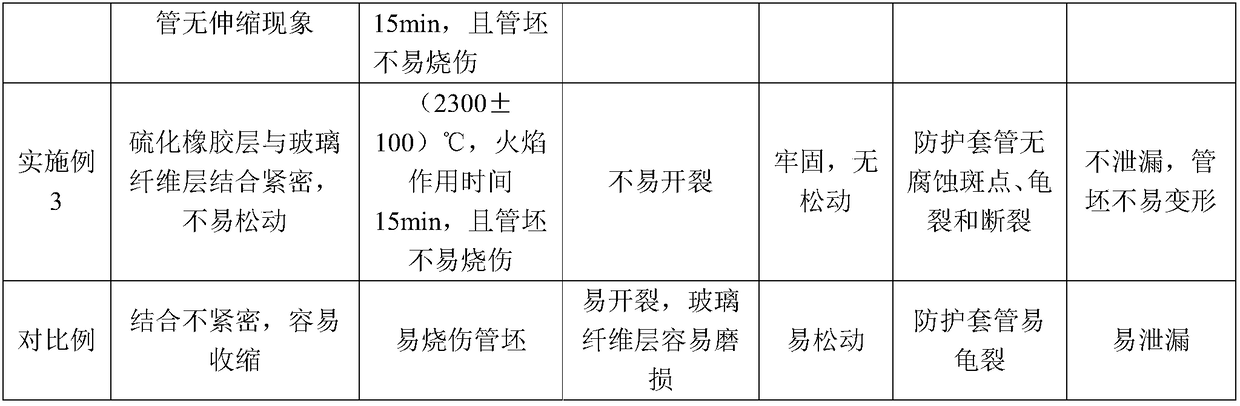

Embodiment 1

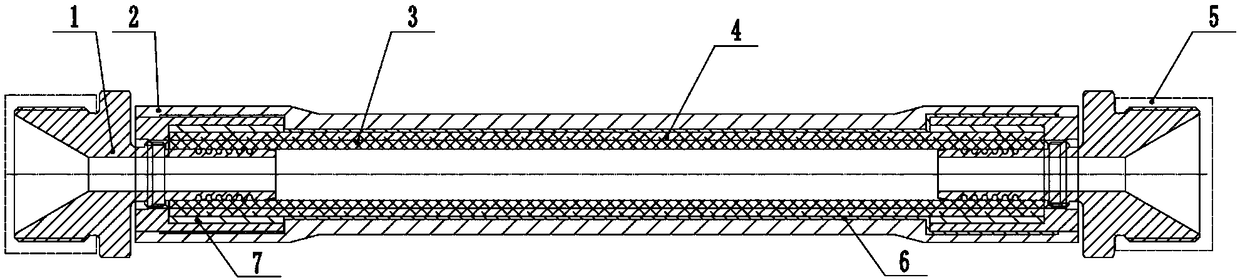

[0029] The vulcanized packaged polytetrafluoroethylene hose assembly of this embodiment is a high temperature and fire-resistant polytetrafluoroethylene hose assembly, such as figure 1 As shown, it includes a hose body and a crimping joint 1 arranged at both ends of the hose body as connectors. The main body of the hose includes an inner polytetrafluoroethylene hose layer (inner tube) 3 and a main road metal braided mesh sleeve (metal reinforcement) 4 wrapped outside the polytetrafluoroethylene hose layer. The main road metal braid A glass fiber layer 6 is provided outside the mesh sleeve, and a vulcanized rubber layer 2 is provided outside the glass fiber layer. The length of the vulcanized rubber layer 2 along the axis of the hose body is greater than that of the glass fiber layer 6, so that the rubber layer covers the glass fiber layer. The glass fiber layer includes a glass fiber fabric layer and a glass fiber thread layer wound around the glass fiber fabric layer. The cr...

Embodiment 2

[0043] In the structure of the polytetrafluoroethylene hose assembly of this embodiment, the thickness of the glass fiber layer is 1.5 mm. The thickness of the end part of the vulcanized rubber layer corresponding to the crimping joint is 2mm, and the thickness of the middle part excluding the corresponding part of the crimping joint is 1mm, and the others are the same as in Example 1.

[0044] The preparation method of the polytetrafluoroethylene hose assembly of this embodiment includes the following steps:

[0045] 1) Prepare the raw materials that meet the vulcanization process, then clean the outer surface of the main metal braided mesh sleeve of the PTFE hose assembly, and then apply glue on both ends of the main metal braided mesh sleeve.

[0046] The compound rubber is prepared, mixed with a rubber mixer, and then pressed to a suitable thickness. Then use a blade to cut into a rectangular parallelepiped of appropriate size.

[0047] Cut the glass fiber cloth into a rectangula...

Embodiment 3

[0055] In the structure of the polytetrafluoroethylene hose assembly of this embodiment, the thickness of the glass fiber layer is 3 mm. The thickness of the end portion of the vulcanized rubber layer corresponding to the crimping joint is 2.5 mm, and the thickness of the middle portion excluding the portion corresponding to the crimping joint is 1 mm, and the others are the same as in Example 1.

[0056] The preparation method of the polytetrafluoroethylene hose assembly of this embodiment includes the following steps:

[0057] 1) Prepare the raw materials that meet the vulcanization process, then clean the outer surface of the main metal braided mesh sleeve of the PTFE hose assembly, and then apply glue on both ends of the main metal braided mesh sleeve.

[0058] The compound rubber is prepared, mixed with a rubber mixer, and then pressed to a suitable thickness. Then use a blade to cut into a rectangular parallelepiped of appropriate size.

[0059] Cut the glass fiber cloth into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com