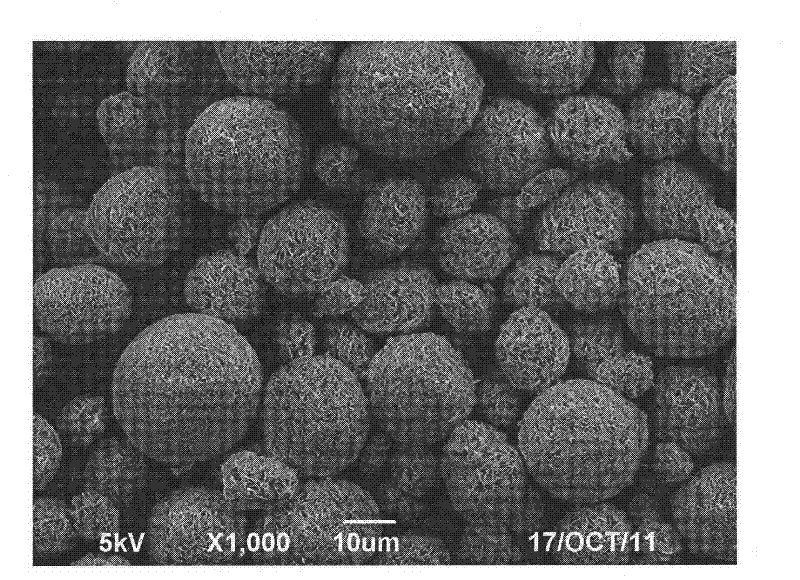

Preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al

A spherical lithium cobaltate, preparation technology, applied in the direction of cobalt carbonate, electrical components, battery electrodes, etc., can solve the problems of poor anti-overcharge performance, lower specific capacity, etc., achieve stable performance, low production cost, simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Use pure water as the bottom liquid, raise the temperature to 40-50°C, start stirring, control the stirring speed at 150r / min, add 25% ammonium bicarbonate, and adjust the alkalinity of the bottom liquid to keep it at 5.

[0031] Preparation of cobalt salt mixed solution: Add magnesium sulfate and aluminum sulfate into the cobalt salt solution with a metal ion concentration of 60g / l, stir to dissolve, mix evenly, and then add nano-sized TiO 2 and lauryl amidopropyl amine oxide, the addition ratio is 0.05% of the cobalt salt solution, stirring to keep TiO 2 suspended state.

[0032] Among them, Co:Ti=120:1, Co:Mg=400:1, Co:Al=250:1.

[0033] The cobalt salt mixed solution and the ammonium bicarbonate solution with a concentration of 25% are continuously pumped into the bottom liquid in parallel, and a precipitation reaction occurs at 40-50°C. The alkalinity of the reaction system is controlled at 10, and the solid content of the slurry is controlled at 260-300g / l.

...

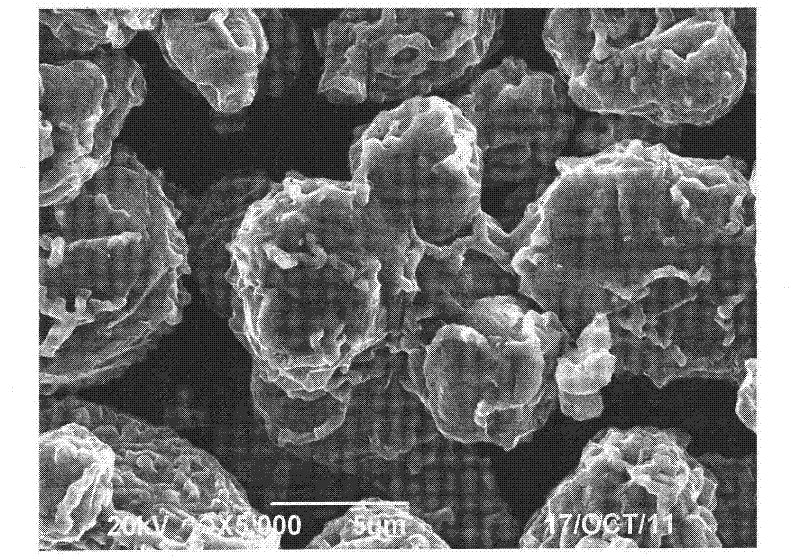

Embodiment 2

[0040] Use pure water as the bottom liquid, raise the temperature to 50-60°C, start stirring, control the stirring speed at 180r / min, add 30% ammonium bicarbonate, and adjust the alkalinity of the bottom liquid to keep it at 15.

[0041] Preparation of cobalt salt mixed solution: Add magnesium chloride and aluminum chloride into the cobalt salt solution with a metal ion concentration of 80g / l, stir to dissolve, mix evenly, and then add nano-sized TiO 2 and coconut acid diethanolamide, the addition ratio is 0.25% of the cobalt salt solution, stirring to keep TiO 2 suspended state.

[0042] Among them, Co:Ti=300:1, Co:Mg=600:1, Co:Al=200:1.

[0043] The cobalt salt mixed solution and the ammonium bicarbonate solution with a concentration of 30% are continuously pumped into the bottom liquid in parallel, and a precipitation reaction occurs at 50-60°C. The alkalinity of the reaction system is controlled at 20, and the solid content of the slurry is controlled at 220-260g / l.

...

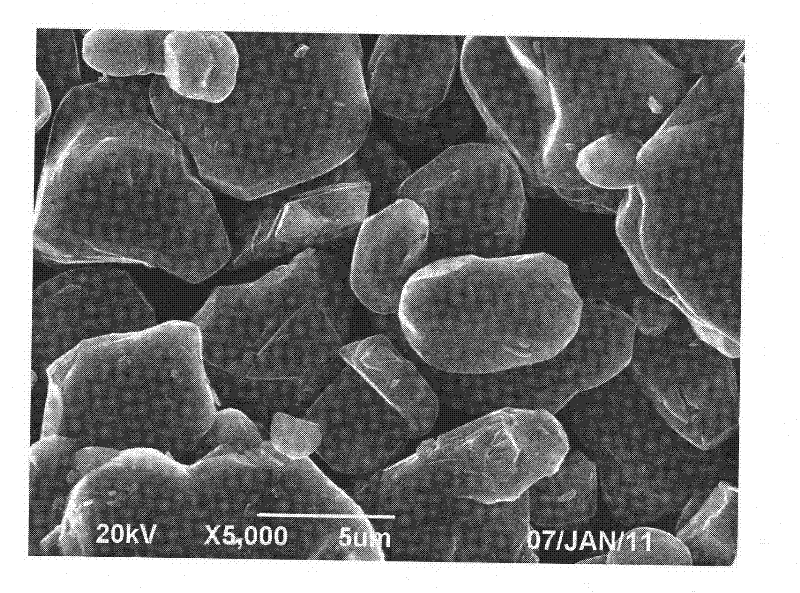

Embodiment 3

[0048] Use pure water as the bottom liquid, raise the temperature to 60-70°C, start stirring, control the stirring speed at 120r / min, add 20% ammonium bicarbonate, and adjust the alkalinity of the bottom liquid to keep it at 25.

[0049] Preparation of cobalt salt mixed solution: Add magnesium nitrate and aluminum nitrate to the cobalt salt solution with a metal ion concentration of 100g / l, stir to dissolve, mix evenly, and then add nano-sized TiO 2 and potassium lauryl ether phospholipid, the addition ratio is 0.43% of the cobalt salt solution, stirring to keep TiO 2 suspended state.

[0050] Among them, Co:Ti=600:1, Co:Mg=200:1, Co:Al=120:1.

[0051] The cobalt salt mixed solution and the ammonium bicarbonate solution with a concentration of 20% are continuously pumped into the bottom liquid in parallel, and a precipitation reaction occurs at 60-70°C. The alkalinity of the reaction system is controlled at 30, and the solid content of the slurry is controlled at 180-220g / l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com