Method for strengthening micro-mixing by using low-frequency intermittent magnetic fields in microchannel

A magnetic field strengthening and intermittent technology, applied in the field of microelectronics, can solve the problems of weak magnetic field and inability to achieve enhanced mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following Example.

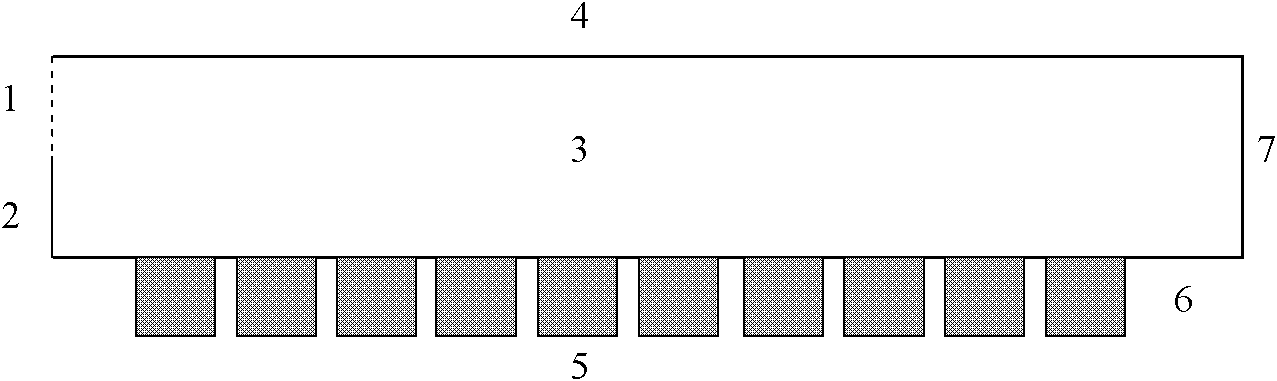

[0050] Step 1: Using electroplating and other micromachining techniques, an array of soft magnets is integrated on one side of the microchannel, and the soft magnets are arranged equidistantly. The microchannels have a width of 100-200 μm and a length of 1-3 mm. 10 soft magnets are processed on one side of the microchannel to form a soft magnet array. The soft magnet material is nickel-iron alloy. The size of the soft magnets is 100×100 μm, and the distance between the soft magnets is 50 μm. The soft magnet generates a magnetic field under the excitation of an external uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com