Novel method for capturing and separating carbon dioxide

A technology of carbon dioxide and a new method, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., to achieve the effects of environmental friendliness, low energy consumption, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

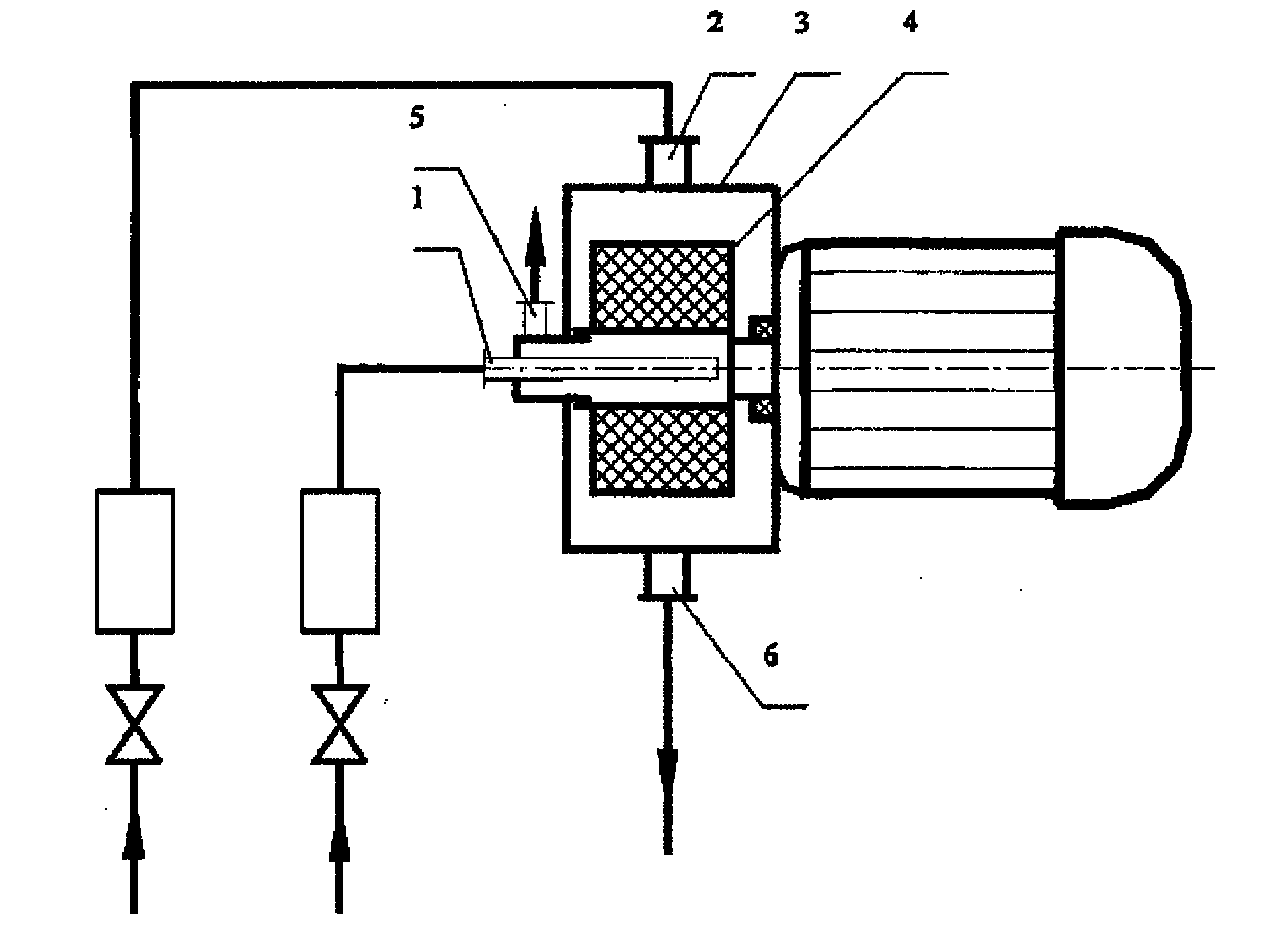

Embodiment 1

[0021] Raw material gas composition: nitrogen: 89.9%, carbon dioxide: 10.0% and the balance is inert gas.

[0022] The absorbent is [Proline Hydroxycholine Salt] ([Choline][Pro]). Adjust the temperature of the system to 20°C, adjust the pressure to 0.1Mpa, start the supergravity rotating bed reactor, adjust the rotor speed to 2825r / m, and then open the control valve of the liquid inlet of the reactor, and the absorbent is distributed by the liquid through the liquid phase inlet pipe 1 The device is sprayed to the inner edge of the supergravity rotating bed rotor 4, and the flow rate of the regulating liquid is 2.65L / h. 2 The mixed gas enters the high-gravity rotating bed reactor through the gas phase inlet pipe 2, and countercurrently contacts with the absorption liquid in the rotor of the high-gravity rotating bed, and performs CO under high-gravity conditions. 2 The trap is then discharged from the gas phase outlet 5 and enters the subsequent section. The gas flow rate is ...

Embodiment 2-19

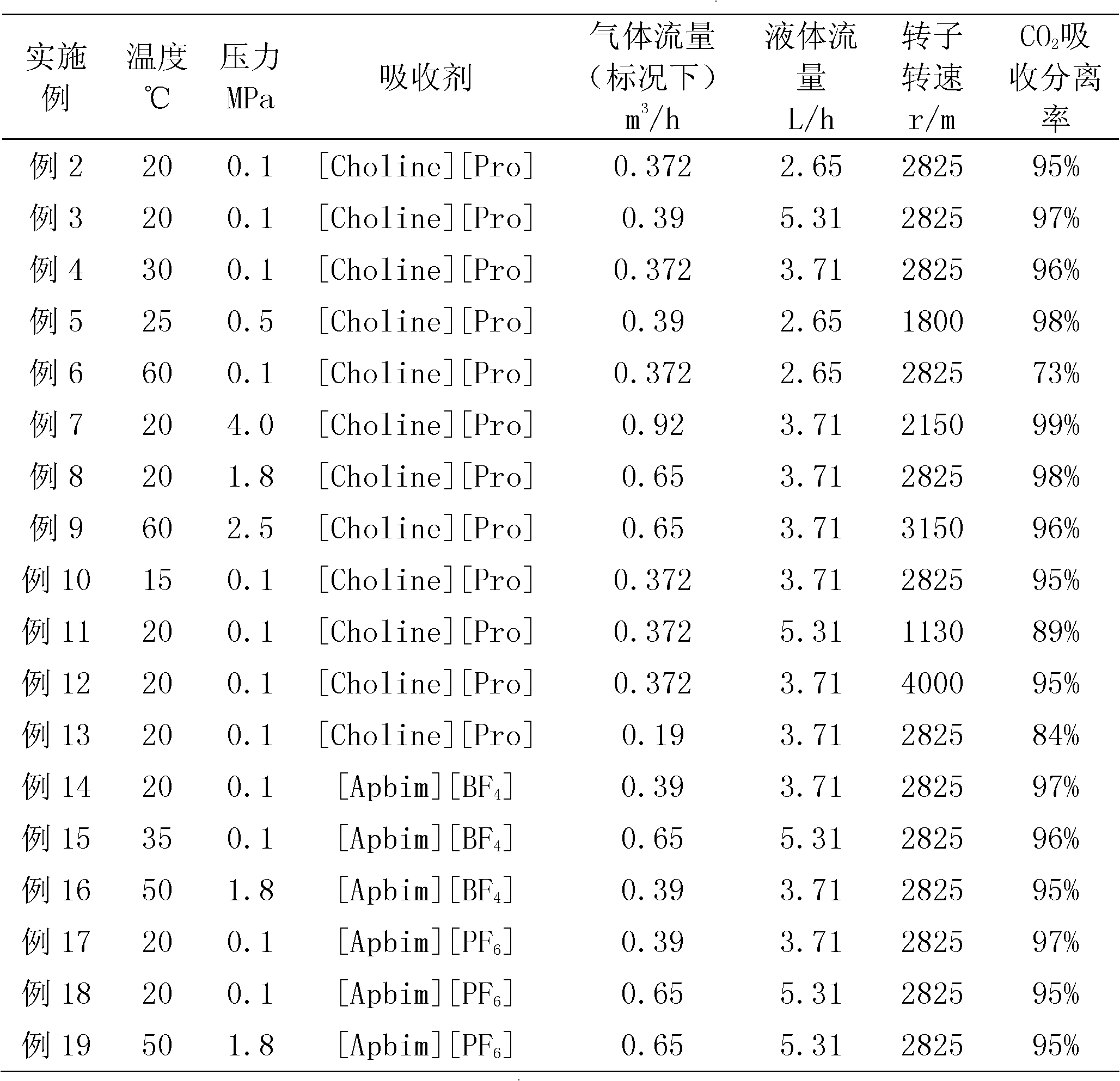

[0024] Process flow and step are with embodiment 1, and the flow rate of temperature, pressure, gas-liquid, rotor speed and test result of each embodiment are shown in Table 1.

[0025] The absorbent is ionic liquid [proline hydroxycholine salt] ([Choline][Pro]), [1-(3-propylamino)-3-butylimidazole tetrafluoroborate] ([Apbim][ BF 4 ]), [1-(3-propylamino)-3-butylimidazolium hexafluorophosphate] ([Apbim][PF 6 ]) and other ionic liquids with amino groups as functional groups or mixtures thereof.

[0026] The volume flow ratio of the absorbent to the mixed gas is 50-500:1.

[0027]Table 1 Process conditions and experimental results of each embodiment

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com