Equipment for measuring gas particles in pipeline by laser speckle and method thereof

A technology of laser speckle and measurement equipment, which is applied in the direction of scattering characteristic measurement, fluid velocity measurement, and measurement devices, to achieve the effects of easy maintenance, high data collection efficiency and accuracy, and expanding the gas measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

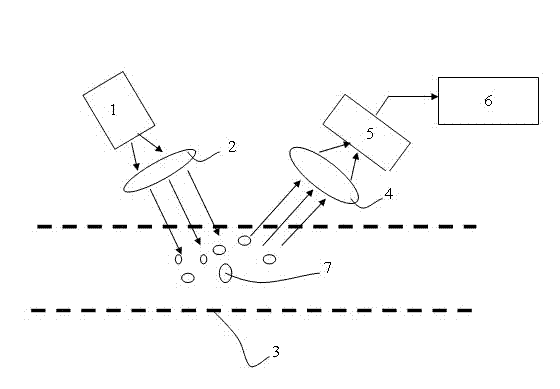

[0028] Example one, as figure 1 As shown, the first lens 2 and the second lens 4 are located on the same side of the gas pipeline 3 under test. At this time, the outgoing light of the laser light source 1 is beam-expanded by the first lens 2 and then enters the measured gas pipeline 3 at a certain angle. The scattering of the gas particles 7 interferes with each other and forms a speckle image on a path separated from the incident light direction at a certain angle. , the optical signal is still emitted from the same side of the gas pipeline 3 to be tested, and is collected by the second lens 4 and then received by the image receiver 5 and transmitted to the image signal processing unit 6 through the optical fiber. The gas speckle diagram formed in the above process is as follows image 3 shown.

Embodiment 2

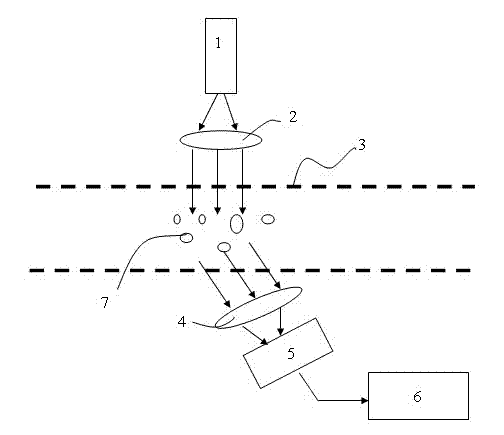

[0029] Example two, as figure 2 As shown, the first lens 2 and the second lens 4 are respectively located on both sides of the gas pipeline 3 under test. At this time, the outgoing light of the laser light source 1 is beam-expanded by the first lens 2 and then vertically incident on the gas pipeline 3 to be measured. When the gas to be measured moves at a certain speed, the nano-gas particles 7 on the path of the laser beam are illuminated and The scattered light is emitted, and the scattering of a large number of nano gas particles 7 interfere with each other and form a speckle image on a path separated by a certain angle from the direction of the incident light. It is then received by the image receiver 5 and transmitted to the image signal processing unit 6 through an optical fiber. The gas speckle diagram formed in the above process is as follows image 3 shown.

[0030] like figure 1 or figure 2As shown, the present invention is like the laser speckle pipeline gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com