Method for preparing dispersion-strengthened copper with high strength and high conductivity

A technology of dispersion strengthening copper and high conductivity, applied in the field of powder metallurgy, can solve the problems of long production cycle, high cost of raw materials, difficult to control, etc., and achieve the effects of high production efficiency, high mechanical properties, and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

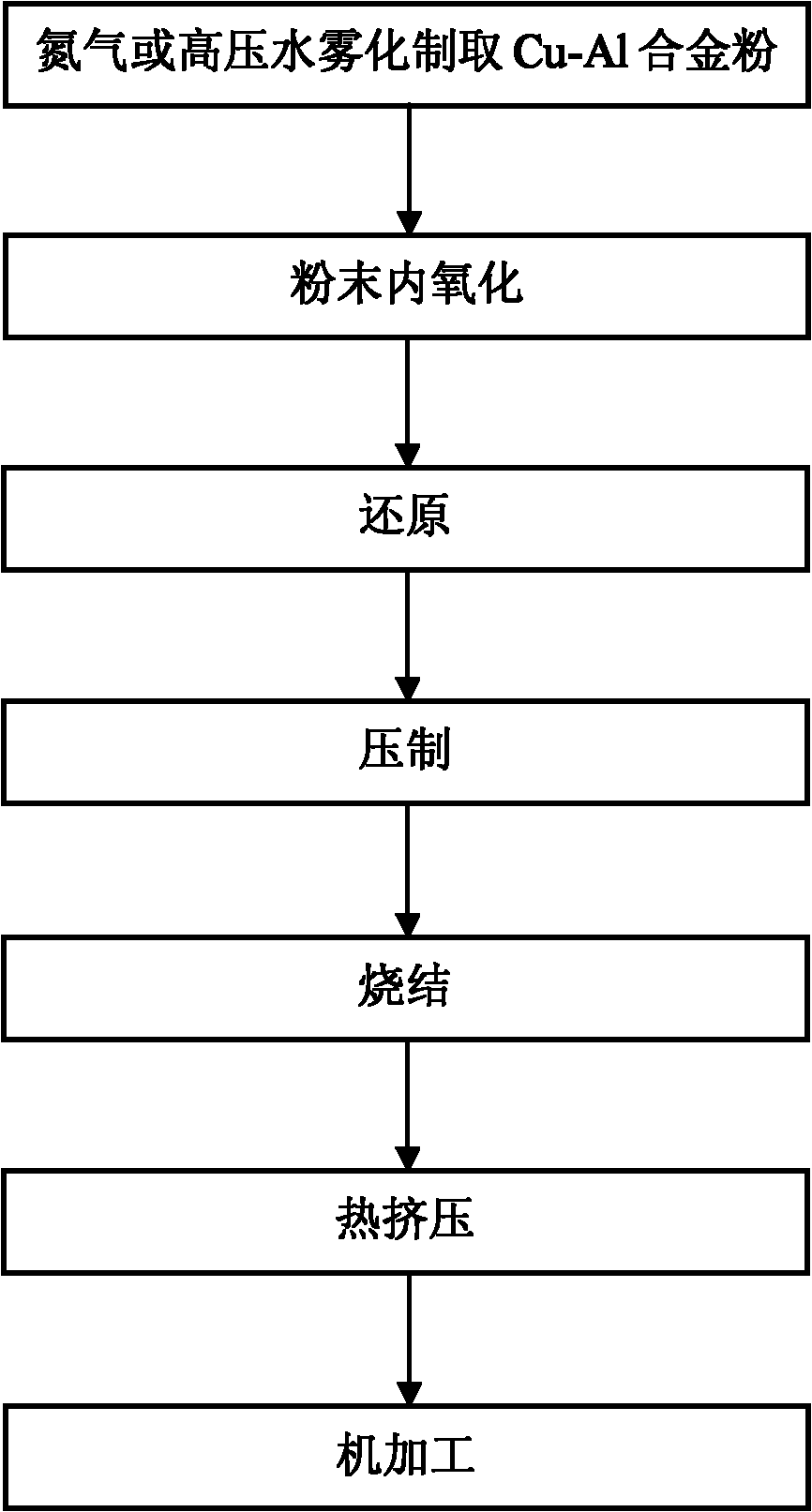

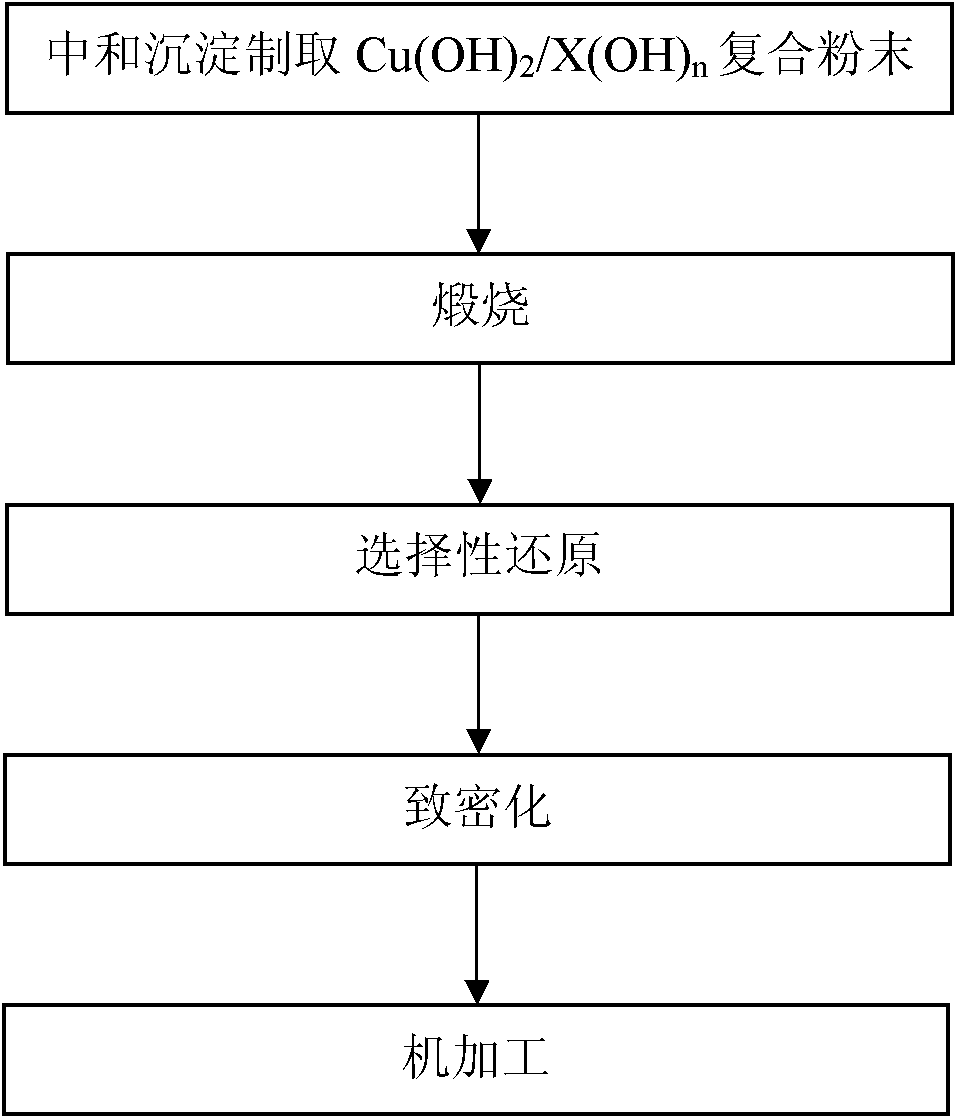

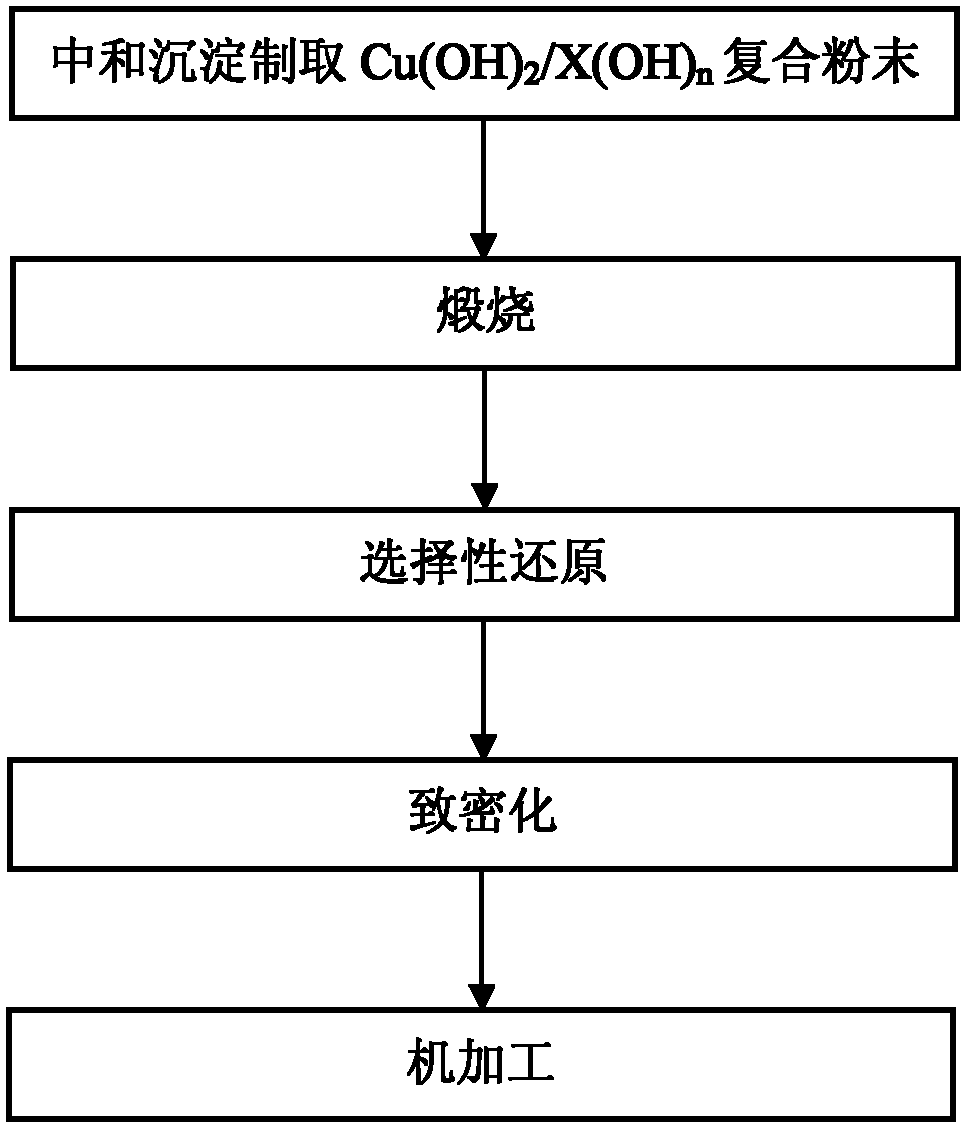

Method used

Image

Examples

Embodiment 1

[0032] Example 1: 0.1 wt% Al 2 o 3 Dispersion strengthened copper

[0033] 1. Cu(OH) 2 / Al(OH) 3 Preparation of composite powder: according to Al 2 o 3 The mass fraction of dispersion-strengthened copper is 0.1%, and Al(NO 3 ) 3 Mix and dissolve, then feed into the co-precipitation reactor at the same time with NaOH solution, and control the pH value of the solution to produce Cu(OH) 2 / Al(OH) 3 Precipitation, the precipitated material is filtered, washed and dried to obtain Cu(OH) 2 / Al(OH) 3 Composite powder.

[0034] 2. Calcination: Cu(OH) 2 / Al(OH) 3 The composite powder was placed in a calcination furnace with a calcination temperature of 300 °C and a calcination time of 2 h to obtain CuO / Al 2 o 3 Composite powder.

[0035] 3. Selective reduction: CuO / Al 2 o 3 The composite powder was reduced in a hydrogen protective atmosphere at a reduction temperature of 400 °C and a reduction time of 2 h to obtain Al 2 o 3 Nano-Al with extremely fine particles and un...

Embodiment 2

[0037] Example 2: 1.0 wt% Y 2 o 3 Dispersion strengthened copper

[0038] 1. Cu(OH) 2 / Y(OH) 3 Preparation of composite powder: according to Y 2 o 3 The mass fraction of dispersion-strengthened copper is 1.0%, the alkaline etching waste solution (copper content is 153 g / L), YCl 3 ·6H 2 O, hydrochloric acid is fed into the co-precipitation reactor at the same time, and the pH value of the solution is controlled to produce Cu(OH) 2 / Y(OH) 3 Precipitation, the precipitated material is filtered, washed and dried to obtain Cu(OH) 2 / Y(OH) 3 Composite powder.

[0039] 2. Calcination: Cu(OH) 2 / Y(OH) 3 The composite powder was placed in a calcination furnace with a calcination temperature of 400 °C and a calcination time of 1 h to obtain CuO / Y 2 o 3 Composite powder.

[0040] 3. Selective reduction: CuO / Y 2 o 3 The composite powder was reduced in a hydrogen protective atmosphere at a reduction temperature of 600 °C and a reduction time of 1.5 h to obtain Y 2 o 3 Na...

Embodiment 3

[0042] Example 3: 2.0 wt% ZrO 2 Dispersion strengthened copper

[0043] 1. Cu(OH) 2 / Zr(OH) 4 Preparation of composite powder: according to ZrO 2 The mass fraction of dispersion-strengthened copper is 2.0%, and ZrCl is added to the acidic etching waste solution (copper content is 176 g / L) 4 Mix and dissolve, and then enter the co-precipitation reactor at the same time as the alkaline etching waste solution (copper content is 172 g / L), and control the pH value of the solution to produce Cu(OH) 2 / Zr(OH) 4 Precipitation, the precipitated material is filtered, washed and dried to obtain Cu(OH) 2 / Zr(OH) 4 Composite powder.

[0044] 2. Calcination: Cu(OH) 2 / Zr(OH) 4 The composite powder was placed in a calcination furnace with a calcination temperature of 500 °C and a calcination time of 1.5 h to obtain CuO / ZrO 2 Composite powder.

[0045] 3. Selective reduction: CuO / ZrO 2 The composite powder was reduced in a hydrogen protective atmosphere at a reduction temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com