Light-diffusion anti-glare nano polycarbonate material as well as preparation and application thereof

A technology of polycarbonate and light diffusion, applied in the direction of light source, point light source, lighting and heating equipment, etc., to achieve the effect of improving stability, extending service life and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

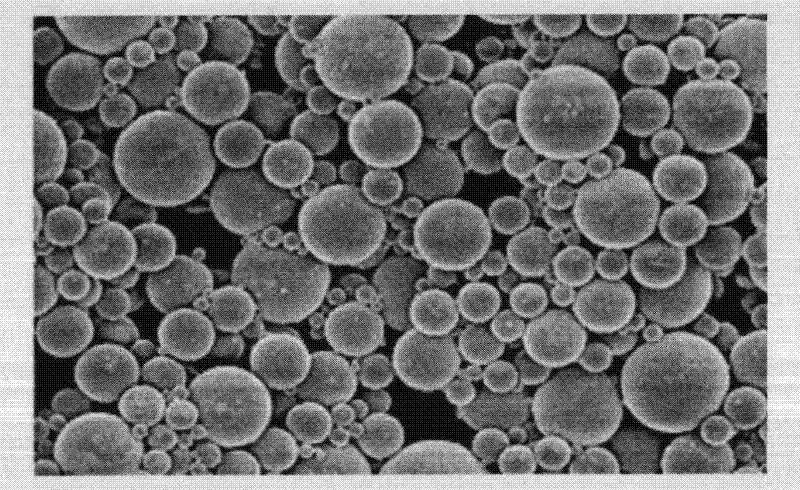

Image

Examples

Embodiment

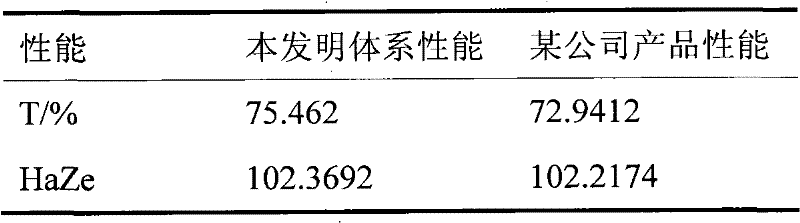

[0037] 1. Formula system of the present invention

[0038] A light-diffusing anti-glare nano-polycarbonate material, which consists of the following components in parts by mass: 100 parts of polycarbonate, hindered phenolic antioxidant: β-(4-hydroxyphenyl-3,5- Di-tert-butyl) 0.1 part of n-octadecanyl propionate, phosphite antioxidant: 0.1 part of tris (2,4-di-tert-butylphenyl) phosphite, polyorganic acid as light diffusing agent 1 part of silicone particles (0.5 parts of polyorganosiloxane particles with an average particle diameter of 10 μm, 0.5 parts of polyorganosiloxane particles with an average particle diameter of 25 μm), lubricant: 0.2 parts of pentaerythritol stearate , the melt index of polycarbonate is 12.4g / 10min, and the refractive index of polyorganosiloxane particles is 1.44.

[0039] 2. Production process of the present invention

[0040] After fully drying the raw materials, weigh 5000 grams of polycarbonate resin (the melt index of the copolymer is 12.4g / 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com