Ultra-thin type polyester film for capacitor and production method thereof

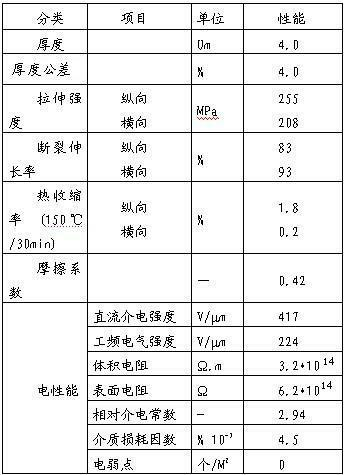

A polyester film, ultra-thin technology, used in fixed capacitor parts and other directions, can solve problems such as large production capacity, poor thermal performance of the film, and low production line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

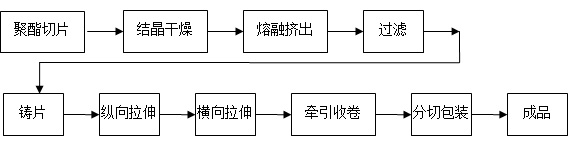

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as figure 1 As shown, the present invention will be further described in conjunction with the examples, but the present invention is by no means limited to these examples.

[0021] Implementation 1: Preparation of special slices:

[0022] 4000-4500PPM SiO with an average particle size of 100nm 2 After surface treatment, 250-280PPM magnesium acetate is added, and the two are stirred together by high-speed centrifugal and assisted by ultrasonic waves, uniformly dispersed in ethylene glycol to form a slurry, and then esterified, polycondensed, cast belt, Pelletizing to obtain modified PET slices, in which SiO 2 The average particle size is 1.0um.

[0023] Additive pre-mixing process:

[0024] ①Premixing→ ②Grinding→③Filtration→④Concentration confirmation,

[0025] Wherein step ①: SiO 2 Pre-prepared into 15% EG slurry, stirred at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com