Electric actuator casing preventing paint from falling

A technology of electric actuators and boxes, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems affecting the appearance of equipment, reduce the possibility of paint peeling, simple structure, and reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

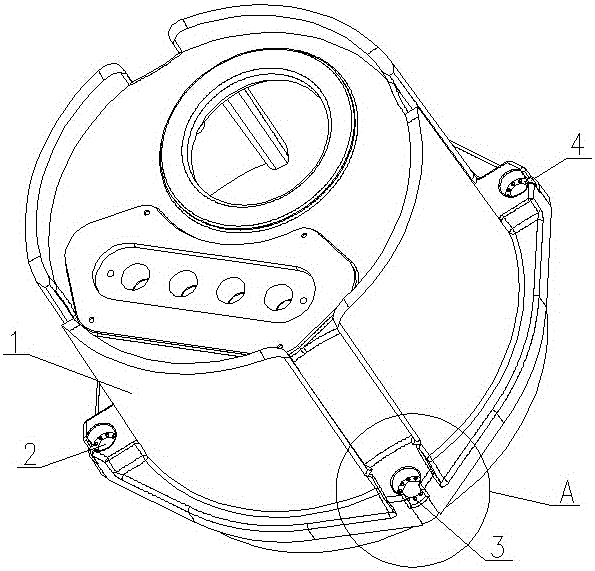

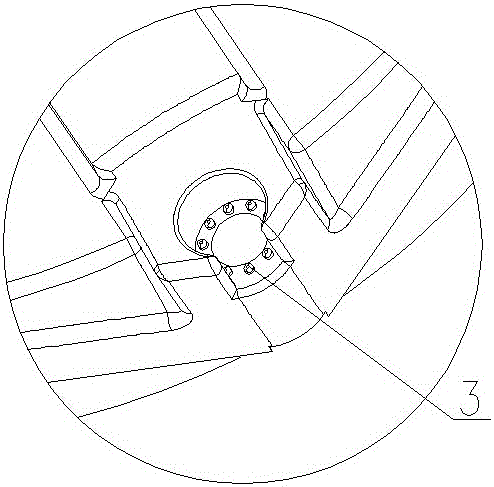

[0013] An electric actuator box that prevents paint from falling off, including a box body 1, a number of screw countersunk holes 2 are arranged around the connection of the lower end of the box body 1, and the step surface of the screw counterbore 2 is Several protrusions 3 are provided, and the plurality of protrusions 3 are evenly distributed around the counterbore hole 2 of the screw.

[0014] Further, the shape of the protrusions 3 is semi-spherical, and the number of the protrusions 3 is 6-12.

[0015] Further, a drainage groove 4 is provided on the side wall of the screw counterbore 2, and the opening direction of the drainage groove 4 faces outward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com